Quite a bit of progress, but I haven't been posting it.

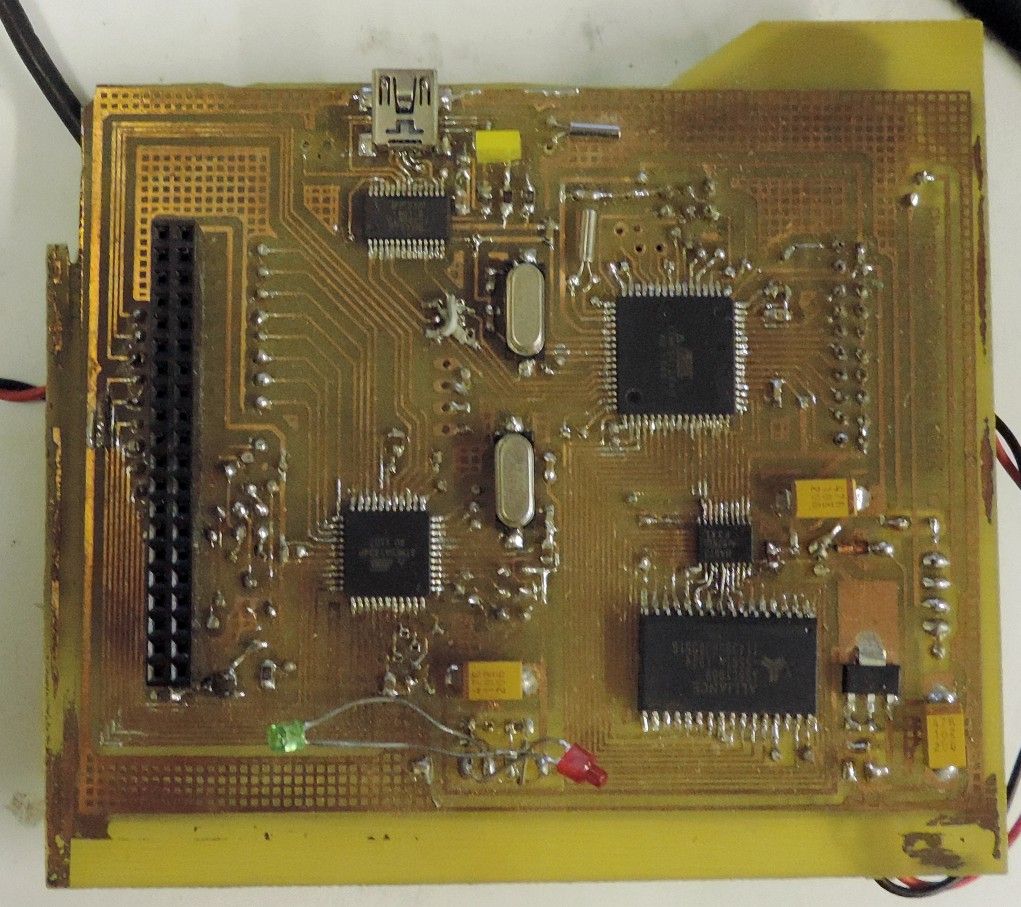

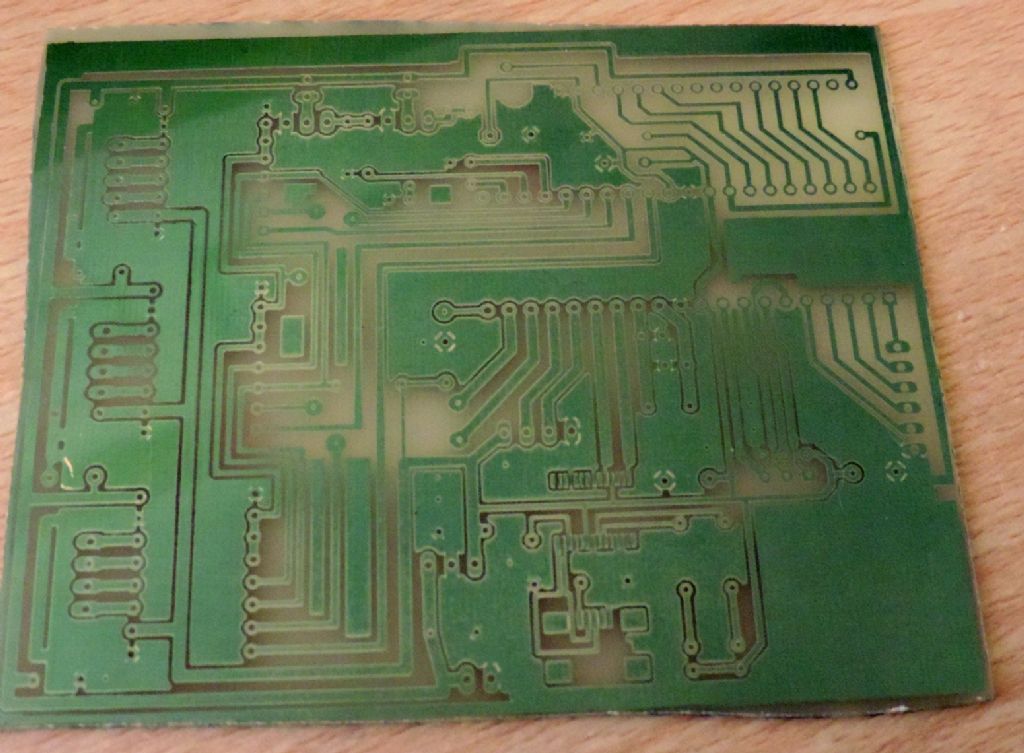

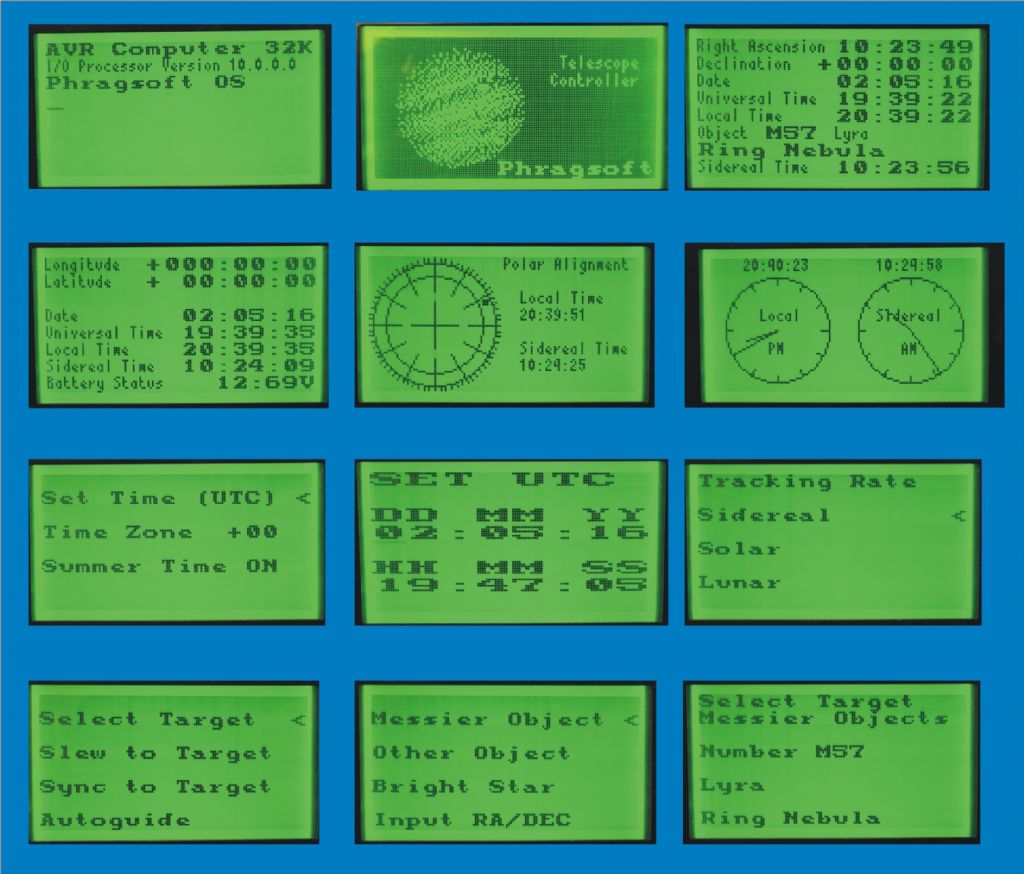

I have redesigned the PCB as instead if a 16×2 alphanumeric display, I will use a 64×128 green graphic display from an old project instead which can display a lot more information, including proper lists of targets.

I have a nice project box made up, with five colour-coded XLR socket on the back: RA, DEC and focus steppers, guide port and dew heaters. On the front the display, chunky brightness control (for ease of use in a hurry), power and an XLR socket for the control handset. The handset is a nice small project box with five coloured push bottoms – I found out why they were cheap on eBay – the bodies have a tendency to melt during soldering!

Found a lovely little unipolar stepper for focus and it had six solder pads, two joined together. I split them and it's magically become a bipolar stepper so I can run it from a polulu, but that's right down the road.

Not much more I can do with hardware until get some molex connectors – I don't want a board tied to the box with dozens of wires. The steppers are fitted to their 'gearboxes' and just await wiring. So for the time being I've started on the software side.

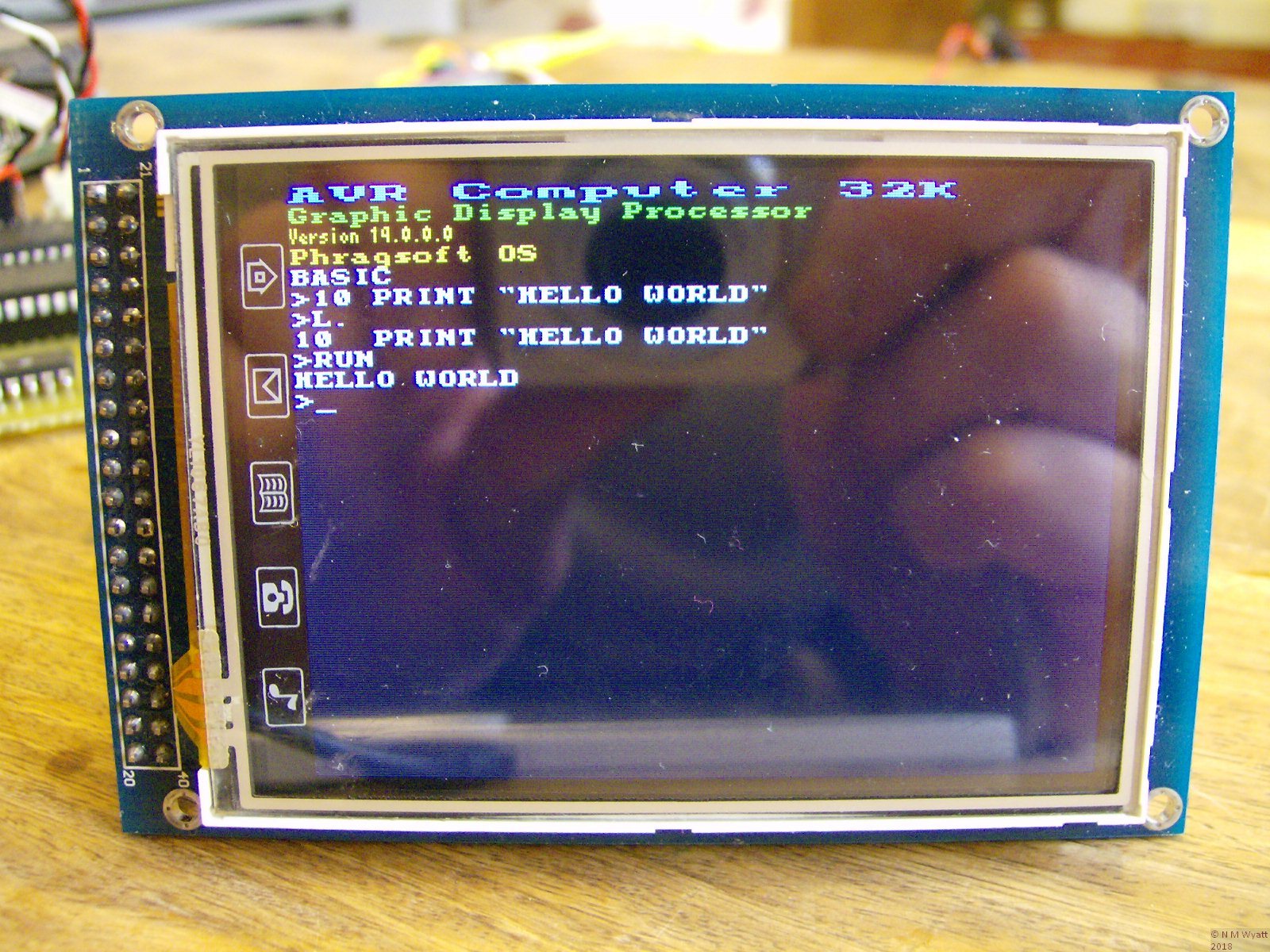

Here's a pic of my 'splash screen' for now.

Neil

Neil Wyatt.

Neil Wyatt.