Using conventional spanners on hardware for which they were not intended, (Such as A/F on BSW / BSF ) is inviting rounded corners and bruised / cut knuckles! As many will testify, slackening a fastener with already rounded corners, using the "correct" spanner can be very difficult, if not impossible.

In extremis, I have carefully filed the flats of a damaged fastener to accept a spanner of another type producing a closer fit. Effectively, this removes the rounded corners, but results in a hybrid with a thread of one form and the head size of a different thread form. But where needs must and all that!

The only "slack" fitting spanners or sockets which are safe to use on BSW/BSF, A/F and Metric hexagons are Metrinch or other flank drive tools.

These, as the description suggests, drive on the flanks of the flats and not on the corners. Sometimes they will slacken fasteners which have resisted all efforts using correctly sized spanners, and on fasteners with damaged corners..

They take some getting used to, since the fit seems to be very slack, but they do work, and are often my first (And therefore only ) choice for slackening or tightening a recalcitrant fastener.

The convention, of using the same size hexagon on a BSF fastener where then thread is one size different from the BSW dates from BS 28

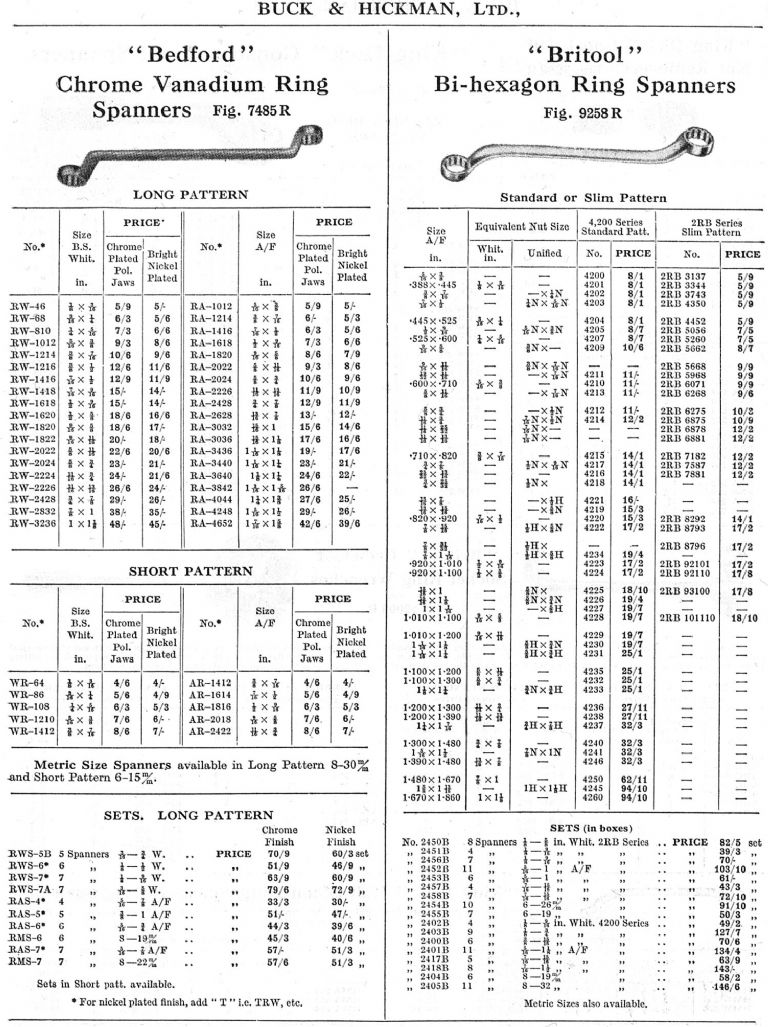

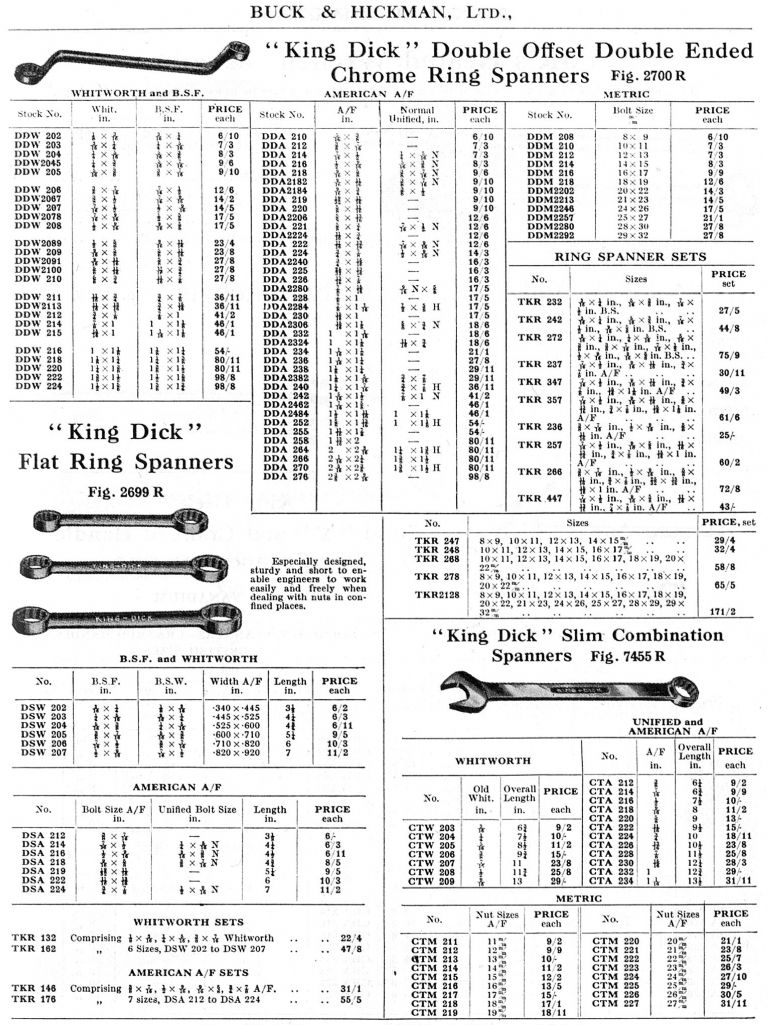

The various BS ( 28, 190 and the later 1083 ) specify the equivalent hexagon sizes. The Britool catalogue 106, illustrates the change by references 5 and 6 on page 128 . The change came about as a means of saving material during WW2, when steel was in short supply.

Howard

Michael Gilligan.

Michael Gilligan.