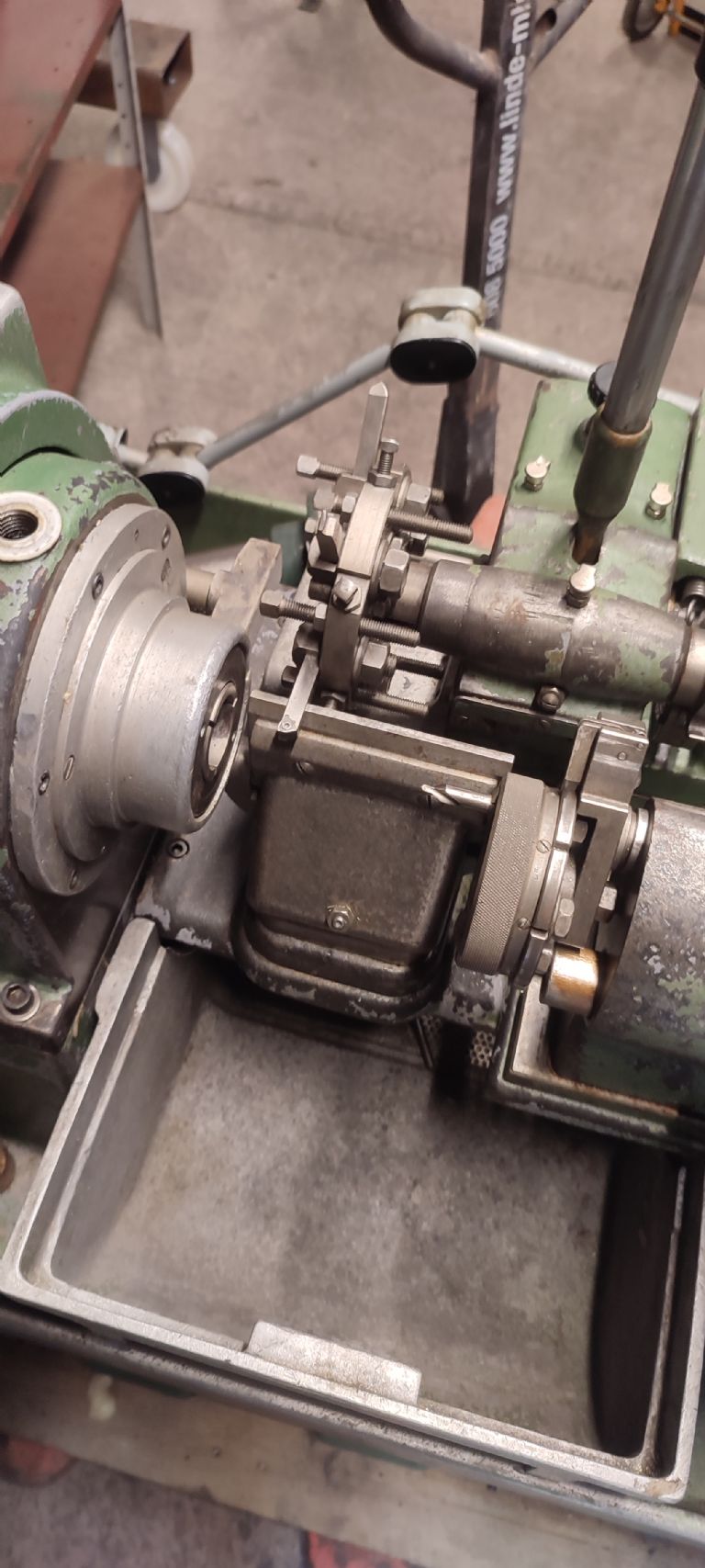

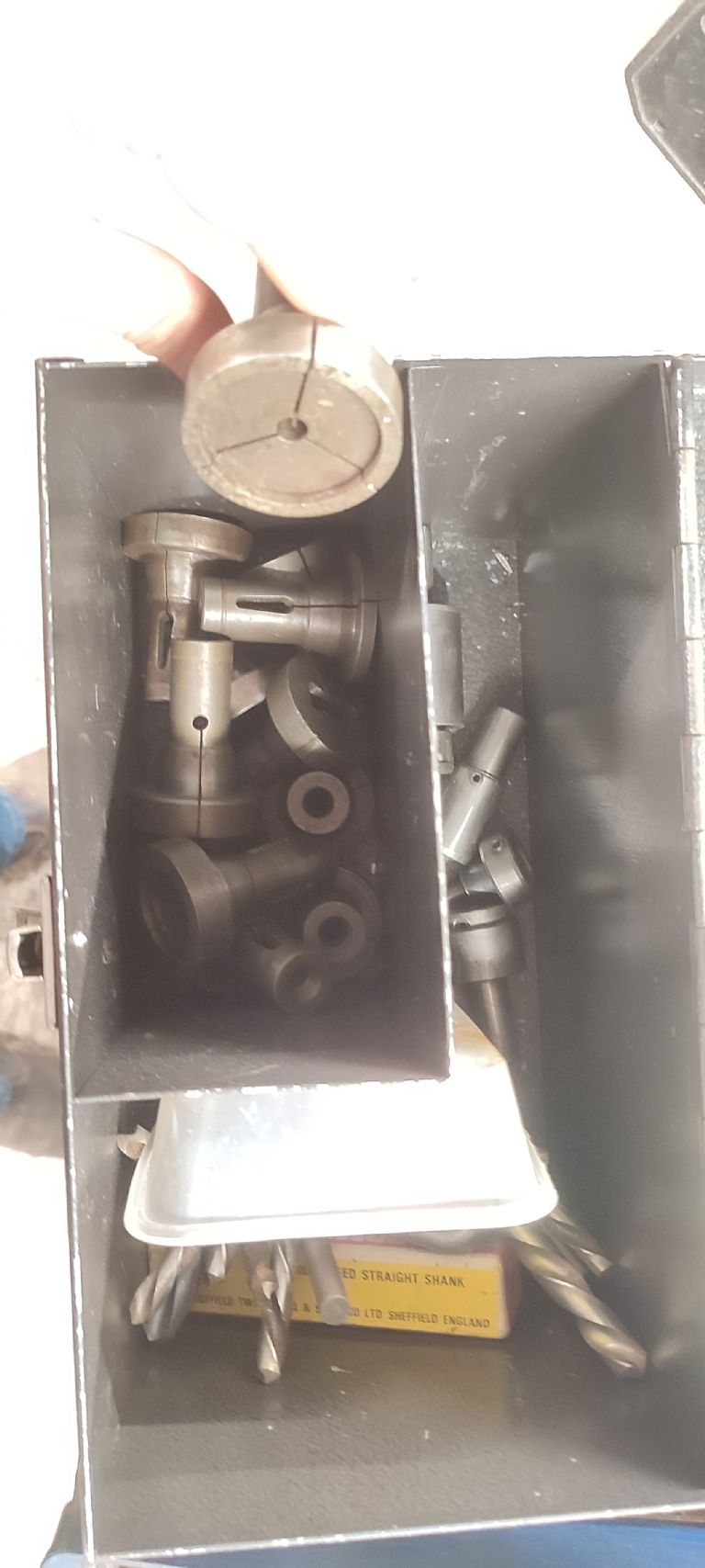

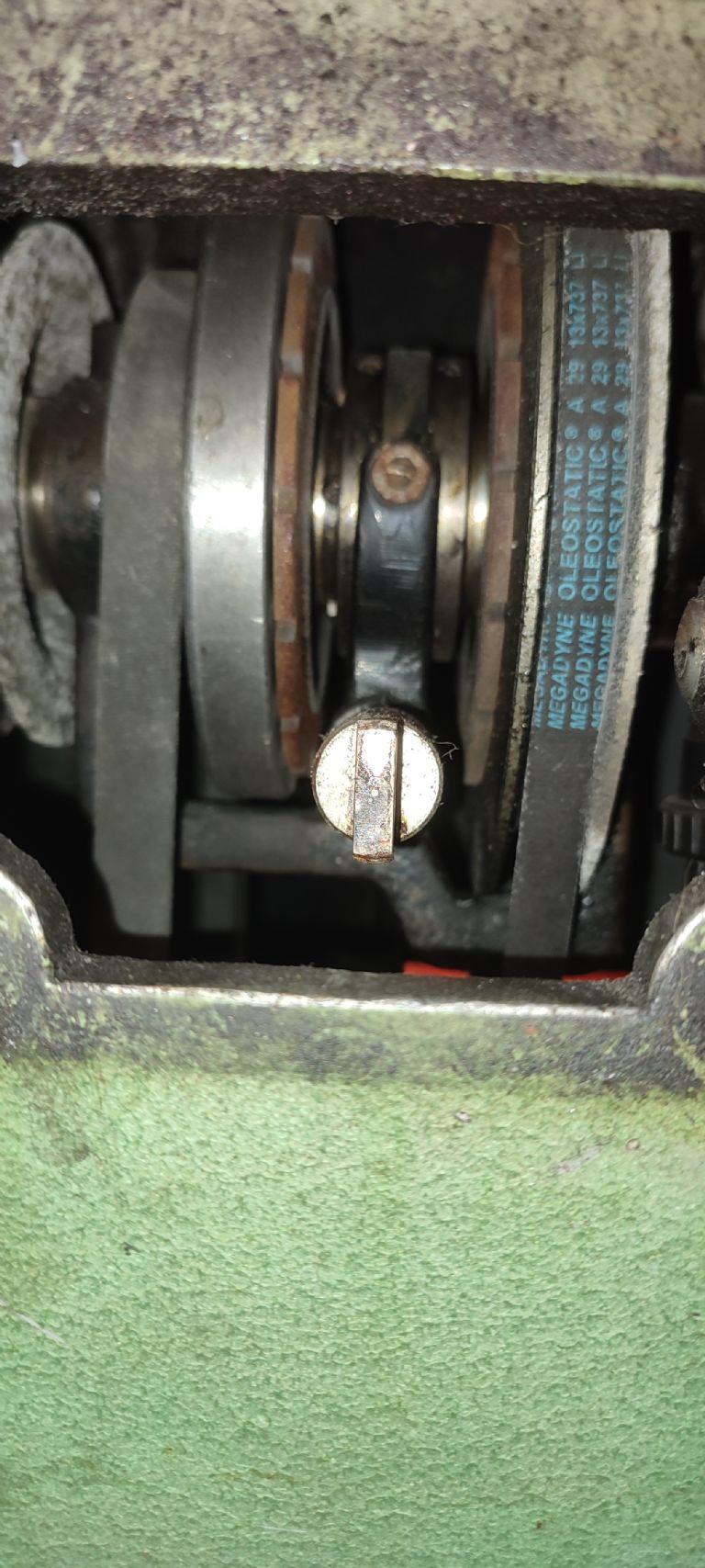

Jacob regarding the clutch, as it hasn’t been used in a while I would move the headstock belt to give the fastest speed you can get and try again, be brutal with it, really brutal. A spray of WD40 or something may help, if the clutches engage too easily they tend to slip so most people seem to set them on the tight side. Regarding feeds, you don’t need the spindle running to bleed the system, just the auxiliary motor, the 3 in 1 motor as it drives the hydraulics for feed, air compressor for the bar feed and coolant pump, this is located directly under the tailstock. Undo the little valves a couple of turns and move little lever at front to vertical or left and leave it there and eventually if you have oil in the system it should work, if it doesn’t it is quite easy to get it all out, usually it’s only the air compressor that gives problems and if it is beyond repair it is easy to just plumb in to the shop airline with a suitable pressure reducer, cannot remember actual pressure but is about 5 to 10 psi. Thinking about it it may be an idea to clean the hydraulic oil reservoir out and treat it to some new oil. For changing belt position on headstock you will find a lump of 3×2 timber handy to just lift the motor while you move the belt.

websnail.