Brian’s Horizontal Stirling Engine

Brian’s Horizontal Stirling Engine

- This topic has 13 replies, 6 voices, and was last updated 26 June 2020 at 20:57 by

Paul Kemp.

Viewing 14 posts - 1 through 14 (of 14 total)

Viewing 14 posts - 1 through 14 (of 14 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- how many times do you have to accept cookies before the nag gets out of the way

- 5

- 24 January 2025 at 20:34

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issues

Newsletter Sign-up

Latest Replies

- Had Another Go

- ME 4761 – Sirius Piston Valve C**k up Corner

- Motor query for 3 phase VFD conversion

- Stanley knives

- Puzzle

- how many times do you have to accept cookies before the nag gets out of the way

- Hemingway Kits

- NEW LOOK – Model Engineer & Workshop

- Brian’s 1″ Minnie Traction Engine

- What Did You Do Today 2025

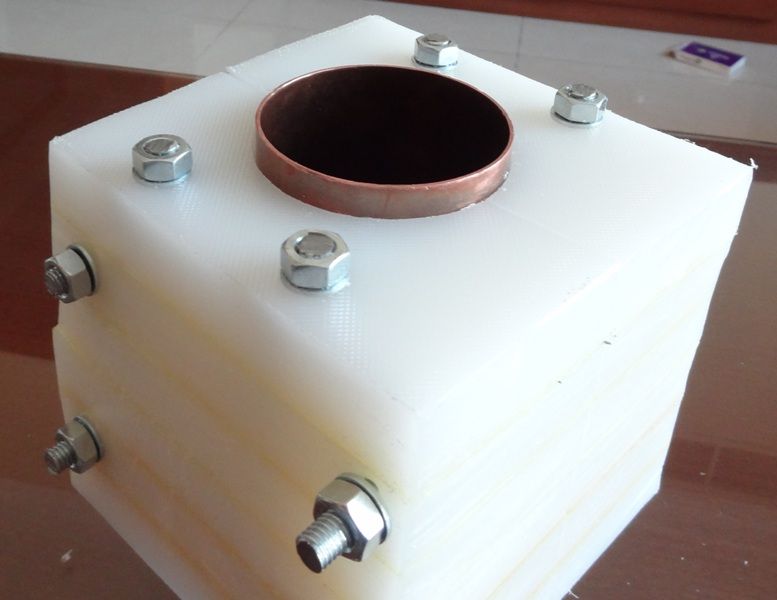

diameter wheel made from HDF laminate flooring with 3mm of lead on the outside of the rim.

diameter wheel made from HDF laminate flooring with 3mm of lead on the outside of the rim.