Posted by Brian Abbott on 23/04/2017 21:01:15:

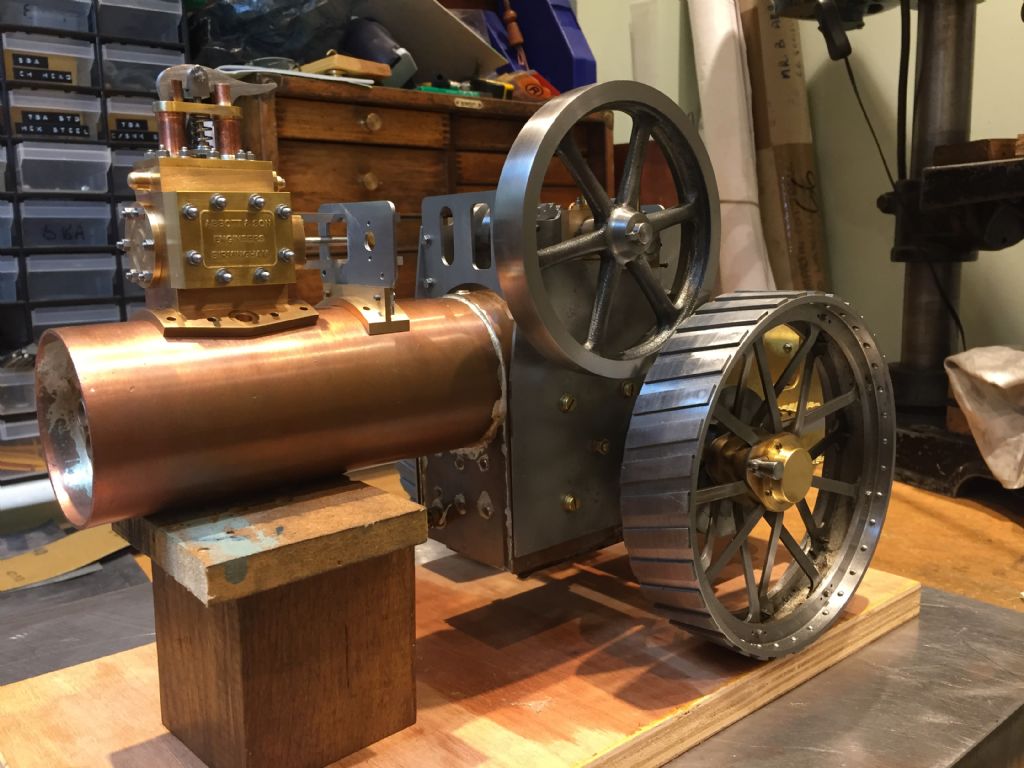

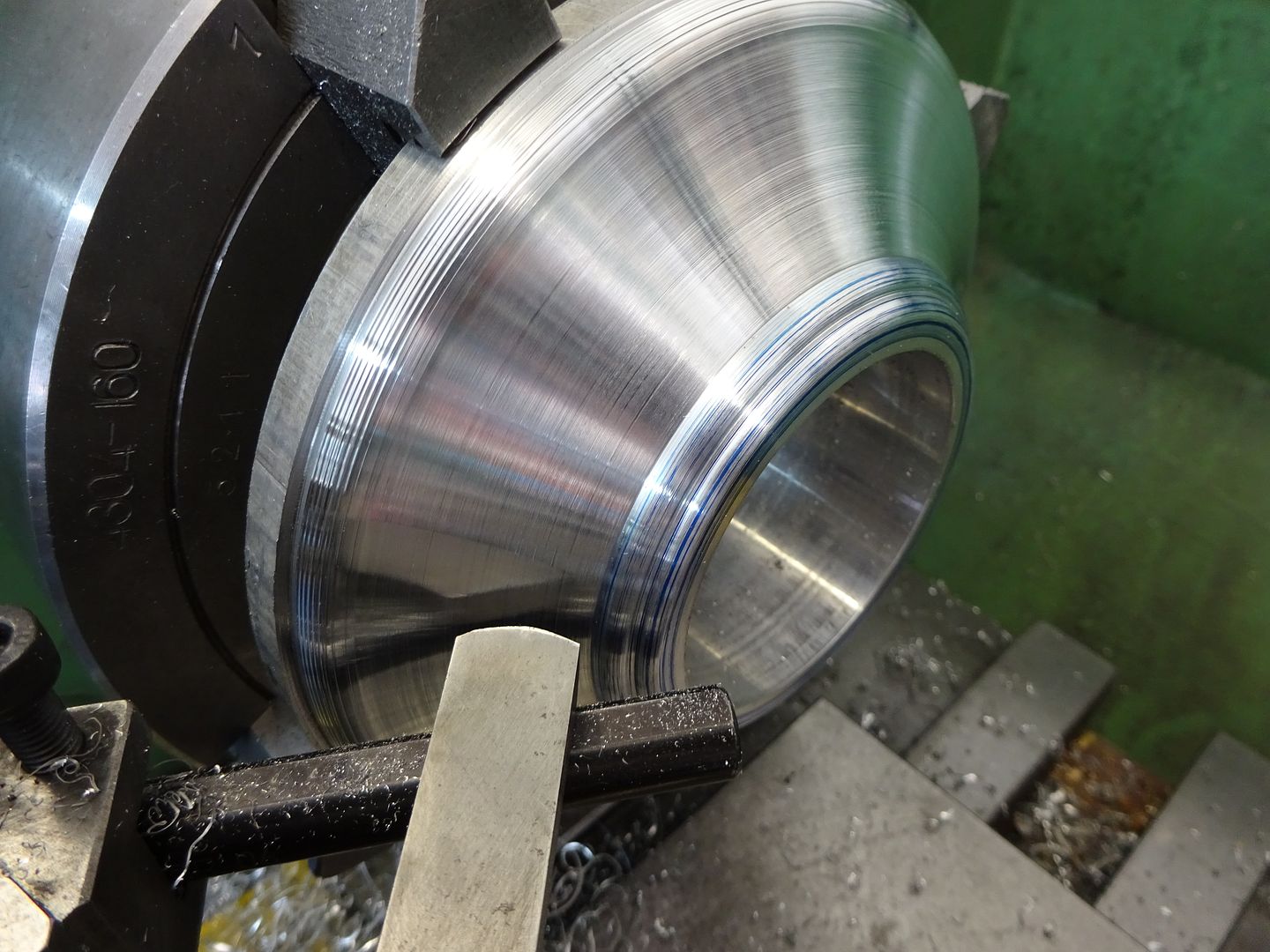

Hello,When i turned the liner on my minnie cylinder i left it about .001" undersize.

On rechecking now its fitted i have a slight taper, measures 0.624" at one end to 0.625" at the other.

Very annoying, the finish is really good and the plan was to give it a quick polish to remove the last little bit.

Do you think lapping would true this up ?hanks.

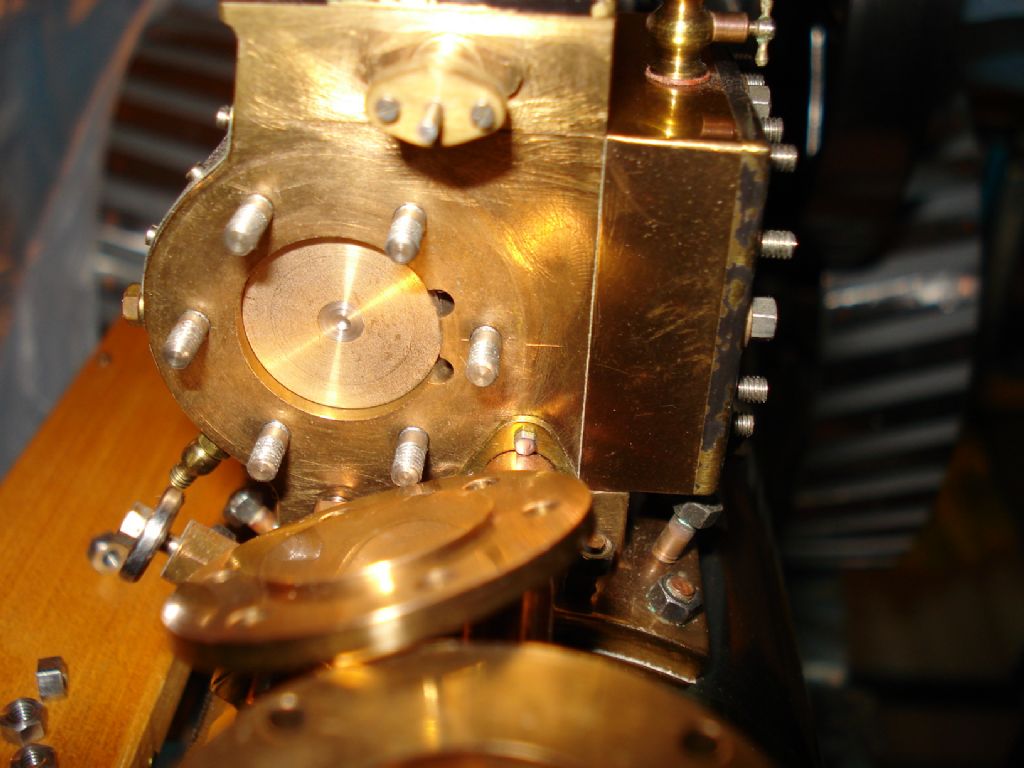

Hello Brian, I had a similar dilemma with the bore, and unsure of the standard of finish necessary. I decided to polish it to size and finish by lapping anyway and before drilling any ports into it.

I made a brass lapping tool about 2" (50mm) in length and as true to 5/8" dia and parallel as poss with shallow grooves spaced 3/16" apart along the length to carry an abrasive (T-cut original) mixed with White Spirit.

It took me a few hours, but the results were excellent and allowed me to make the piston a real good smooth fit.

Brian Abbott.