Bump: So that Brian's last post is not lost in the festivities. Happy New Year everyone.

Brian,

It looks like you find yourself in the same situation as I was about 40 years ago when I was attempting to make a Minnie boiler. No matter how I tried, I did not seem able to get the work up to temperature before I exhausted the flux, which was the correct high temperature type for C24, as it was then.

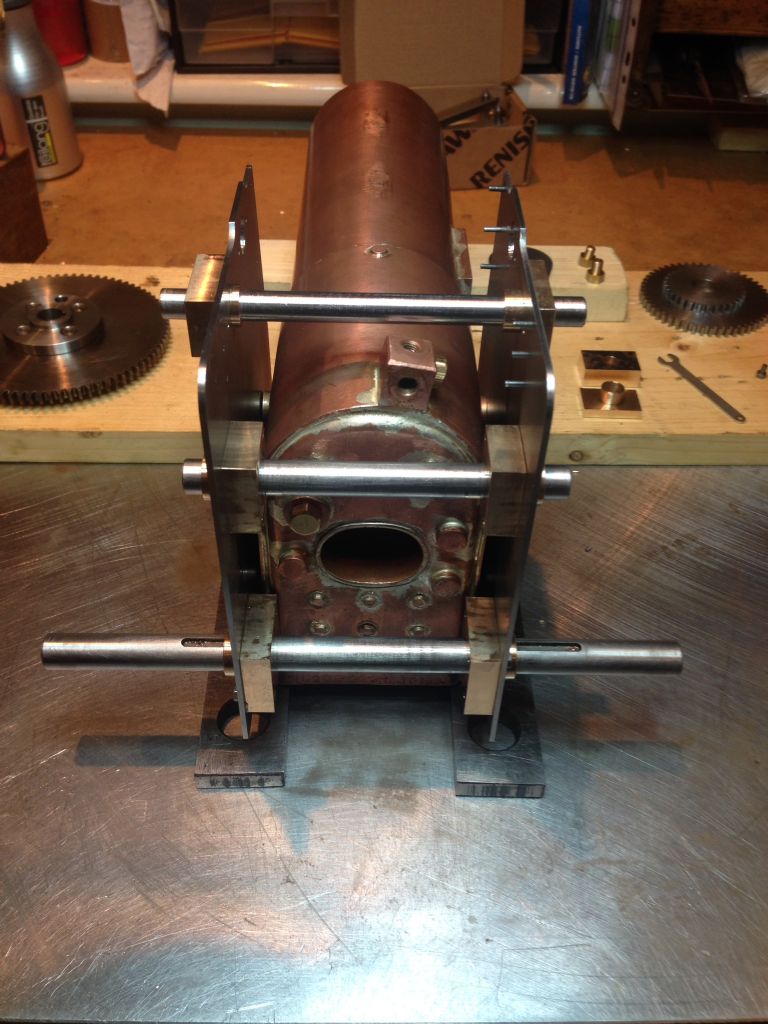

I still have the shell – throat-plate, barrel, thickening plates, and pump pad, which I managed to assemble and silver solder OK with some help at night-school using oxy / acetalene – (very scary – for me) – which gas do you turn off first?.

The firebox did not, however, want to be silver soldered by me with my propane set-up which was a Bullfinch 1250 / 38mm dia / 12.6 kw / consuming 907 grams of gas per hour and which also kept blowing out! I had a makeshift hearth with lots of coke (as suggested by Mr Mason in his book) to surround the work and conserve the heat.

I gave in and bought a boiler which may not be an option for you as the prices have increased quite a lot since I paid £25 at Reeves in the early 70's.

I did some research last year (Sievert and Bullfinch websites) into propane torches, hearths and methods in preparation for a second attempt. Apart from a lot of successful small test pieces, some more Sievert burners and remade firebox plates – no further progress.

Your Sievert 2941 / 28mm / 7.7 kw output is quite a bit smaller than I was trying to use. I'm not saying that this is not enough – I just don't know, those more skilled at this may say – why are you wasting so much gas.

Another bit of information to bear in mind is the maximum off-take possible from different sized bottles:

A 3.9kg bottle – 25000 btu or 7.3 kw :: 11kg bottle 50000btu or 14.6 kw. etc.

Silver soldering a boiler, even a small one, is a difficult and potentially costly skill to learn.

I hope someone will be along soon to offer some practical advice, which I will also gladly welcome.

Regards

Phil

Brian Abbott.