Hello everyone,

I know I am kind of resurrecting an old thread here, sorry in advance if that's the wrong approach.

I recently got the Bullfinch Brazing torch, and I would appreciate your input with a problem I am having:

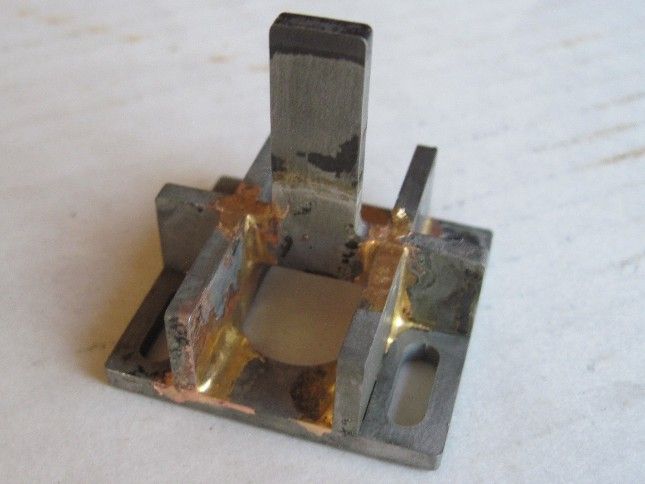

I am trying to braze some 8mm threaded bar to a section of 30x30x3mm mild steel

The steel is drilled 8mm and the threaded bar is sitting in hole. The steel is set on, and partially surrounded with fire bricks, but I am struggling badly to reach a temperature where the brass brazing rod runs into the joint.

Is the steel section too big for this torch?

Or would it be a flux issue? (I ordered brass brazing flux, but the company sent me silver solder flux-I am temporarily using this)

The steel gets red hot easily enough, but the rod doesn't melt (or at least certainly doesn't flow) by touching the steel – only when the flame is directly applied to it.

Would appreciate your thought,

Thanks,

Á D

Bill Phinn.