Yes on using something on both ends of the beads, yes on one side of the metal needing to be the oppisite of the other. No on it being a 2 part mold, that would be more appropreaite to the shaping of the press of the brass sheet.

I do however hear what you're saying I think, but would worry about how heavy that would make the tool. I;m a girl…bad forearms…lifting heavy stuff isn't goinig to happen.

Are you saying that filing is a possiblity? Isn't that gong to be hard to do? Also I'm not sure I could afford a block of brass. But I totally agree that bending/folding is going to be hard.

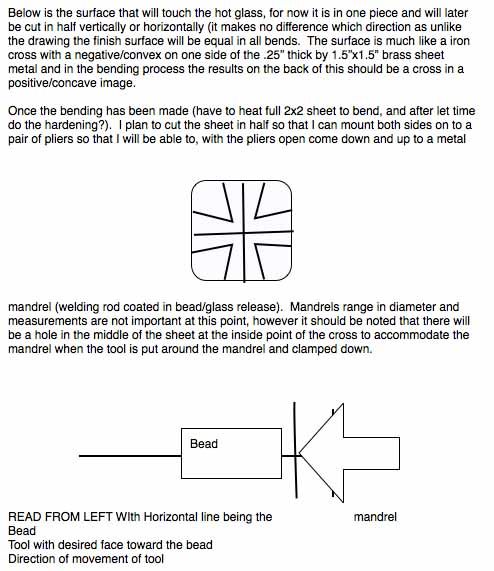

I thought of the optic mold type of thing that MikeW mentioned early on but abandend it because 1) I don't have access to the lathing/cutting/shapping tools and 2) because a bead is made on a long mandrel with the bead anywhere on the mandrel but far enough for your hand to hold away from the flame. This means you may be able to get the end of the bead pressed, but the end toward your hand isn't going to do that. It was back to metal press tool that would be able to clamp around the mandrel.

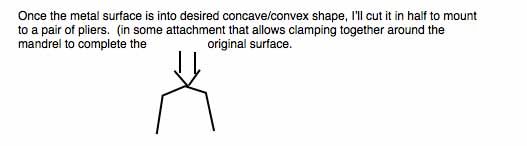

Sounded simple at first, I can see it (except for the attachment to the pliers) but can't explain it. On the soldiering, he said said hard silver soldier and Handi flux. I think I'm going to have to go to double or triple sheets of more bendable brass and attach them together. That gets me out of the metal folding/bending and leaves me with how to soldier them together…but then again maybe that last bit is how I'll have to do it…soldier the layers together. I think I'll go work with a piece of paper to see if simple folds would work. I've figured out how to cut a wood block but would need to find a woodworker. It's alway something. I'll definitely take a picture and post if this ever comes to fruitition.

Thanks for the helps.

pj newt.

, but it did lead to the next thought).

, but it did lead to the next thought).