Posted by Peter Simpson 3 on 21/11/2022 10:04:40:

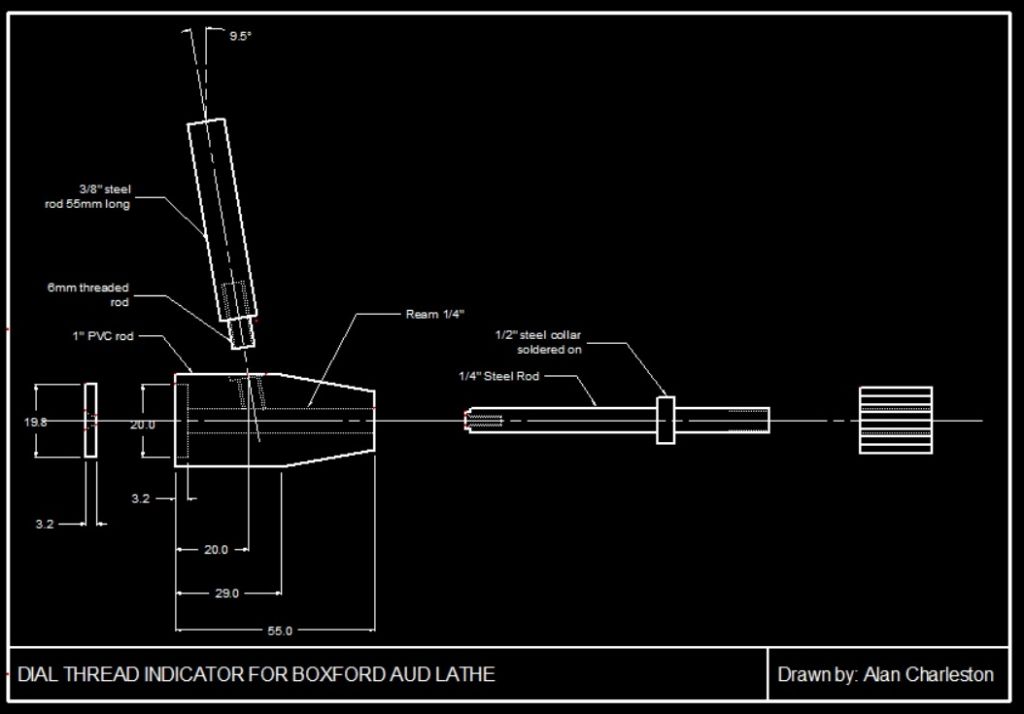

My Boxford lathe has a screw cutting gear box but does not have a thread dial indicator. These indicators look to be as rare as hen's teeth and rather expensive. Looking at photos of the indicator the only issue I would have in making an indicator would be machining the gear wheel that engages with the lathe lead screw. Could anybody give me some tips as where to start and what equipment would be required to produce a suitable gear wheel.

Is it a metric lathe? Thread Dial Indicators match well to turn per inch thread systems, but not to pitch thread system like metric. For that reason metric lathes don't always come with a TDI. Instead, the cutter is reversed out without disengaging the half-nut, and the cutter never loses sync with previous cuts. The same system works on Imperial lathes.

The advantage of a TDI is speed, because, after a cut, the half nuts can be disengaged so the carriage can be manually reversed as fast as the operator can manage. Then there's a delay while he waits for the TDI to align, at which point he engages the half-nuts for the next cut. It can go wrong, misreading the TDI or by catching the half-nut slightly early or late. I'm not sure the metric method is that much slower in practice, but it depends on the thread being cut.

The first problem cutting a gear, is deciding how many teeth are needed! This depends on the lead-screw pitch.

After that, the gear need not be particularly wonderful : just 'good enough' to engage without damaging the lead-screw. Not much power is absorbed turning a dial, so the teeth just have to fit well enough to turn it. They're usually made of brass, but I think aluminium or plastic would be adequate.

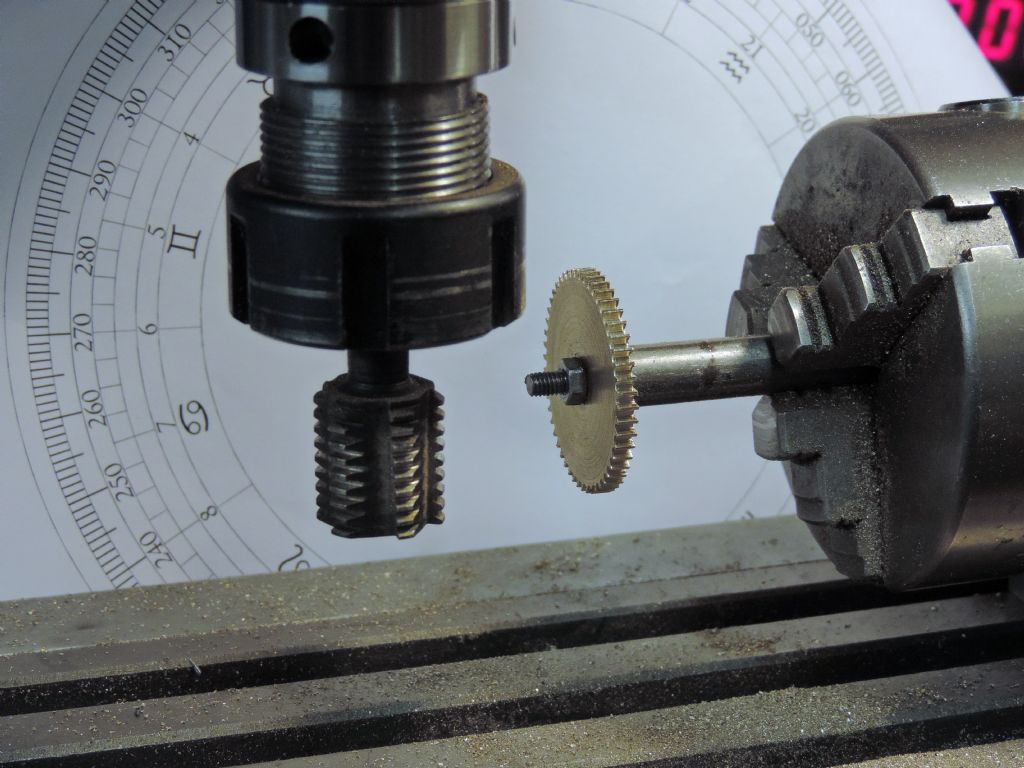

Easiest way is to buy one! Next easiest is a 3D printer. After that, I'm a fan of rack cutting, which is described here. This example was made by Neil:

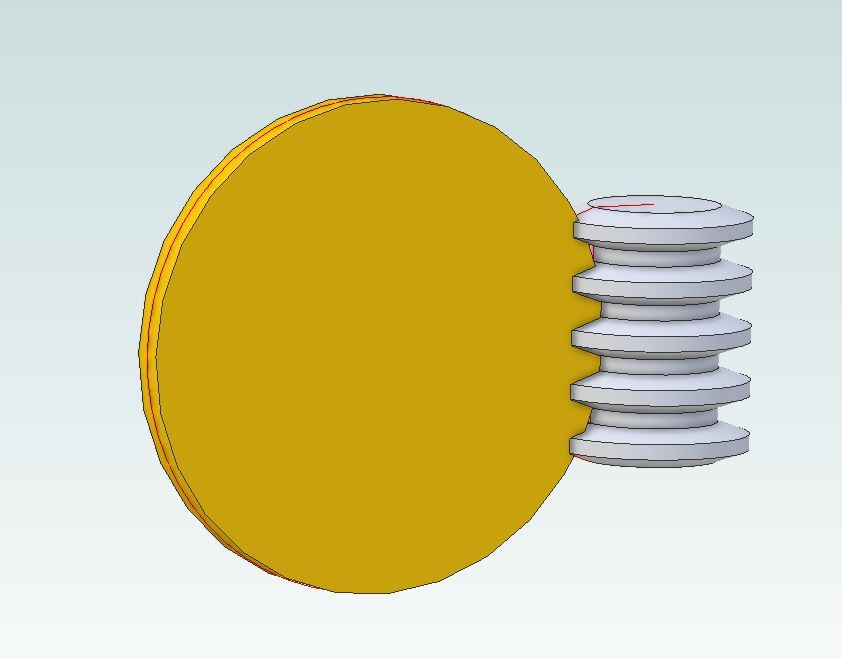

The cutter is made by turning a thread of the required pitch, and then grooving it to provide cutting edges and reliefs. This image from Jason shows the how the gear teeth are developed, several teeth each pass, and they are involutes.

Dave

Grizzly bear.