Chris is good at asking simple questions that provoke complicated answers!

Inserts aren't made in the huge variety of shapes and sizes they are to suit hobby users. Rather they are made in a wide choice of configurations to allow production to be optimised. Getting tooling right is much more critical when manufacturing thousands to a price, and considerable effort is often put into setting up to maximise profit. Typical factors leading to an optimum choice of insert material, size, geometry, angle and rake include:

- The material being cut, for example Aluminium cuts better with a sharp insert, mild-steel prefers a blunt edge.

- The characteristics of the machine available – no need for hefty inserts on a weedy machines, no sense in pussy-footing with a big one.

- Chip control – in production it's better for cutters to consistently produce small chips of metal rather than long spirals of sharp swarf because managing swarf is a serious problem when a machine makes a ton or two of it per day.

- Power consumption. Generally the more brutal the cut, the less power is needed remove a given amount of metal. But the insert has to be sufficiently strong and heat resistant to cope with the stress. Industrial cutting with carbide considers 850C to be "moderate heat", and it's not unusual to go as high as 1500C. This effects insert choice, because reducing a £1M electricity bill by 5% is well worth doing.

- Coolant. Some inserts crack or otherwise react badly to particular cooling methods, and it's often preferable to machine dry.

- Type of cut. Facing, lengthwise, chamfering, profiling, and whether or not a shoulder or other tight operation is needed all influence insert choice. Inserts shaped for best finish tend not to last as long as inserts designed for roughing out, and the latter will also remove metal faster for less power. Round nosed cutters are good for extended tool-life and deep cuts, but are more likely to chatter than small nosed cutters, which are also capable of better finish. Positive rake tools reduce cutting forces (useful on slender jobs) and provide more clearance, which is useful when boring because the sides of the job curve in towards the tool. Negative rake inserts are stronger and last longer, but have less clearance and put lots of force on the job.

- Cost! It may be cheaper to change cheaper inserts than it is to use the best available. The economics depend on the job. Not sure myself it's a good idea for hobbyists to spend big money on long-lasting inserts when dropping them is a hazard.

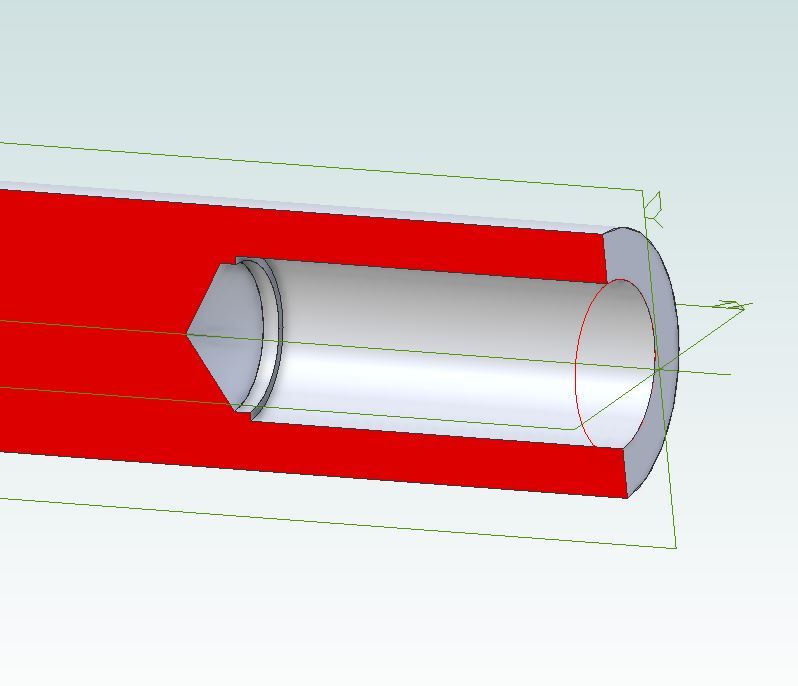

Most of this complexity is irrelevant in the average home workshop! In practice, I mostly go for small noses, (low cutting force and good finish), but for most work the choice is non critical. My favourite boring bar carries a triangular insert, handy because it's easy to tell when a blind bottom is being turned flat. My smallest boring bar, which will nearly gets into a 10mm hole has a rhombic insert: it cuts perfectly well but it's easier to use on through holes, unless a small trench at the bottom doesn't matter. With care the rhombic and triangular cutters both do much the same job. I also have a large boring bar fitted with a square insert. It bores large through holes quickly, but is useless for blind ones.

The kind folk at ArcEuroTrade (and others) sell the type of holders and inserts most useful to hobbyists. Unless something special is being done, I don't see much advantage in plunging into grown-up catalogues and selection criteria. For a long time I only had a 6mm set of right, left, facing and boring holders with rhombic inserts: later I found value in having triangular and square inserts as well, but I managed perfectly well with rhomboids for a couple of years.

Insert holders are another game again. They range from quite expensive to faint on the spot extraordinary. I think the best are engineered for best possible strength and anti-vibration properties. Jolly good in an industrial context, but I'm not sure a chap with a Sherline would get much value from inserts and holders designed for 1500°C cutting and several kilowatts at the spindle.

Dave

Edited By SillyOldDuffer on 12/11/2019 17:43:57

John Haine.