Good question.

I think this is a case of asking too much of the mill and cutters. Maybe also the Aluminium is soft and gummy, tearing rather than cutting, causing the motor to work extra hard.

Hole-saws are best for thinnish sheet metal rather than going deep, because swarf builds up in the slot, and having to drive lots of teeth puts a heavy demand on the motor.

Taking the cut slowly (lowish feed-rate) with plenty of paraffin or WD-40 and frequently stopping to clear swarf might help. About 500 rpm by my rule of thumb, but experiment with faster and slower. The mill's motor probably delivers more power and torque at higher rpm, but what suits the motor may not suit the saw.

So I'd change technique. Instead of trying to saw a large hole in one go, I'd twist-drill as big as I can – 13mm because I'm too mean to buy a Blacksmith's Drill.

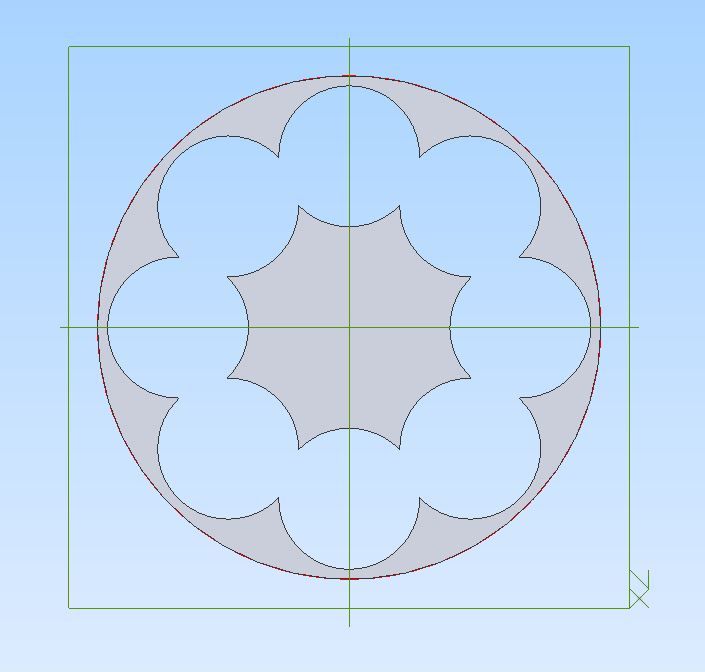

Then bore the 15mm hole out to whatever size is needed with a boring bar. For this a boring head is needed:

Though they cost a few bob, boring heads are a valuable accessory. Boring does both deep and wide holes. As there's only one cutter, which can be adjusted to take very find cuts, it doesn't overload the motor. The holes are also considerably more accurate and straighter than anything done with drill or hole-saw. Main disadvantage is the time taken. If you want to make big holes quickly, a large powerful machine is needed to drive the cutter. Otherwise we have to slow down!

Jason's method is a good compromise: chain drilling lots of small holes removes metal quickly and then the boring bar only has to tidy up, which doesn't take long. The mill works inside it's comfort zone throughout, and swarf collecting and mincing in the slot isn't a problem.

Dave

David Brown 9.