Welcome to the wonderful hobby Tom.

Whereabouts are you in the land.

If in darkest Norfolk, or surrounds, you are more than welcome to spend a day or more perusing my collection of books.

What did you make with your previous machines?

Ditto your new toys?

I started off with an original Unimat and thought I could build LBSC's Tich!

Well that turned into a laugh, BUT fortunately a kindly soul at the JLS, my namesake, whispered some very sage advise in my rear, and I soon had an Emco V10P with mill.

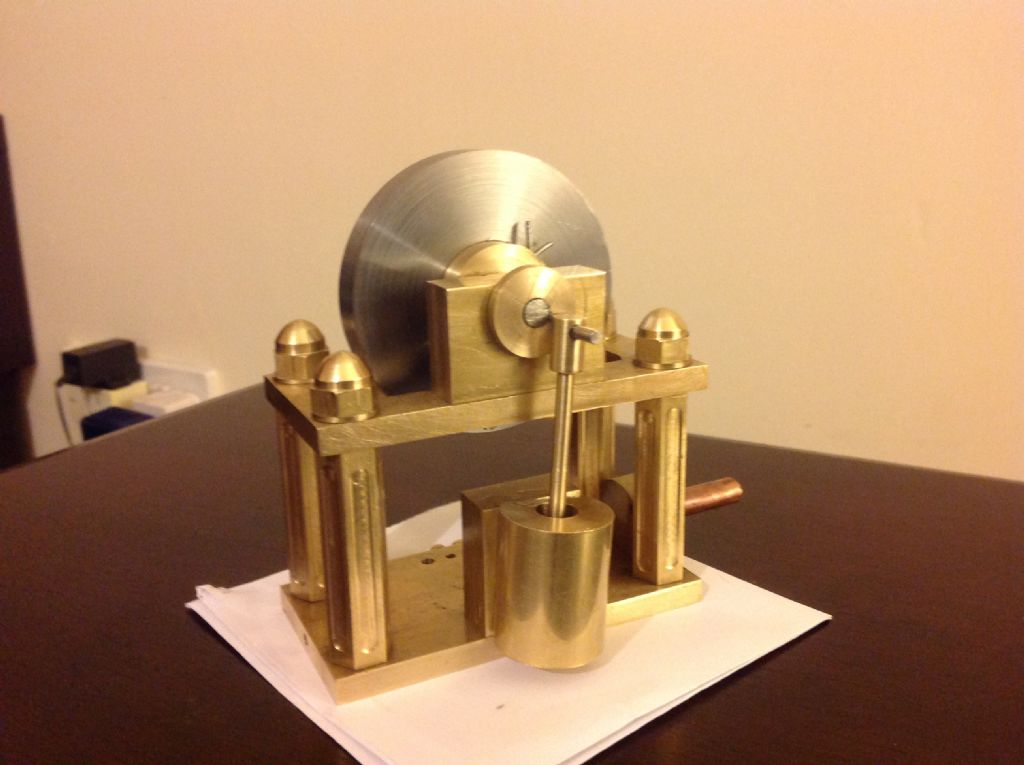

My first stationary engine was the ubiquitous oscillator, powered by a Stuart Turner boiler.

Seeing that little thing spin around with steam exiting everywhere was exilirating.

There are books on building just about everything, covering steam and ic engines to tools, for hand or lathe use.

Only you will know where your preference lies once you start making swarf.

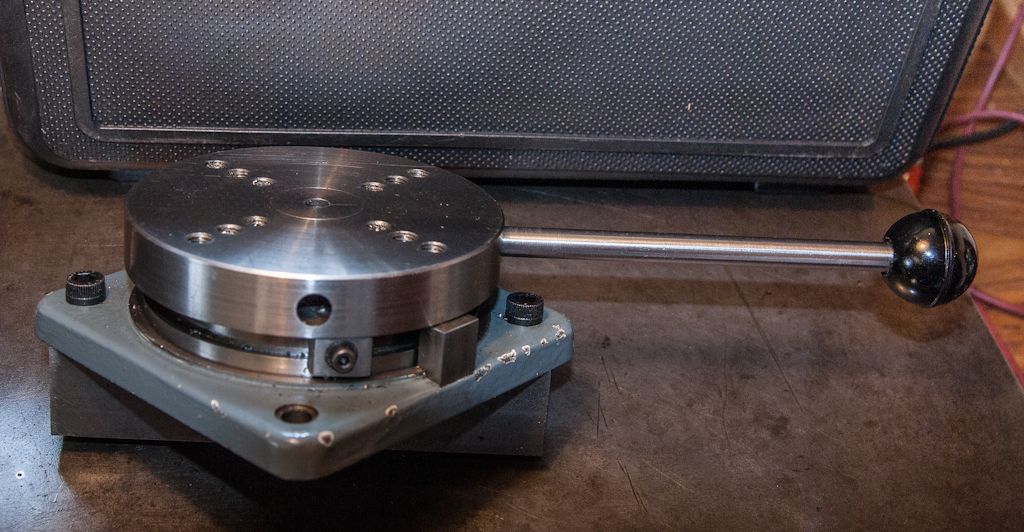

May I suggest a simple hand/lathe tool/accessory that will get you using your machines first, before agonizing over which direction to take.

My first serious project was the Geo. H. Thomas tapping/staking tool, and it taught me a lot more about working metal than reading all the books available.

Start with something easy to gain experience on how your machines operate.

Oh, and do find a container and mark it 'Scrap'  It will come to your rescue on many a time in the future.

It will come to your rescue on many a time in the future.

Geoff – Good to see newcomers entering the hobby.

edit: c changed to v in fourth sentence, but original still valid

Edited By OuBallie on 14/03/2014 09:28:16

Tom Gullan.

It will come to your rescue on many a time in the future.

It will come to your rescue on many a time in the future.