My Replies in bold but I will also ask Diane to get Chris to comment

Part 1: No dimension is given for the width of the top face. Somehow I ended up at 1.688, (11/16" ). But, it's not too critical.

Yes does seem to be missing but 1 11/16" looks to be ok on a non critical part

Part 2 is more involved and has a lot of errors I'll try to explain them. They are only for those components that I have tried to make, so there could be others!

Liner.

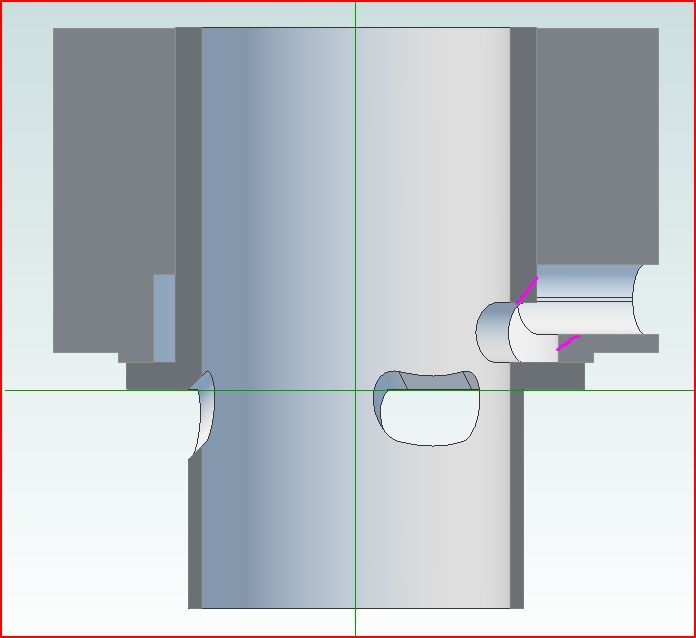

The 0.075 dimension for the top of the exhaust port from the underside of the flange is smaller than the dimension of the exhaust port! I think it should be the thickness of the flange.

Agree looks like the flange thickness

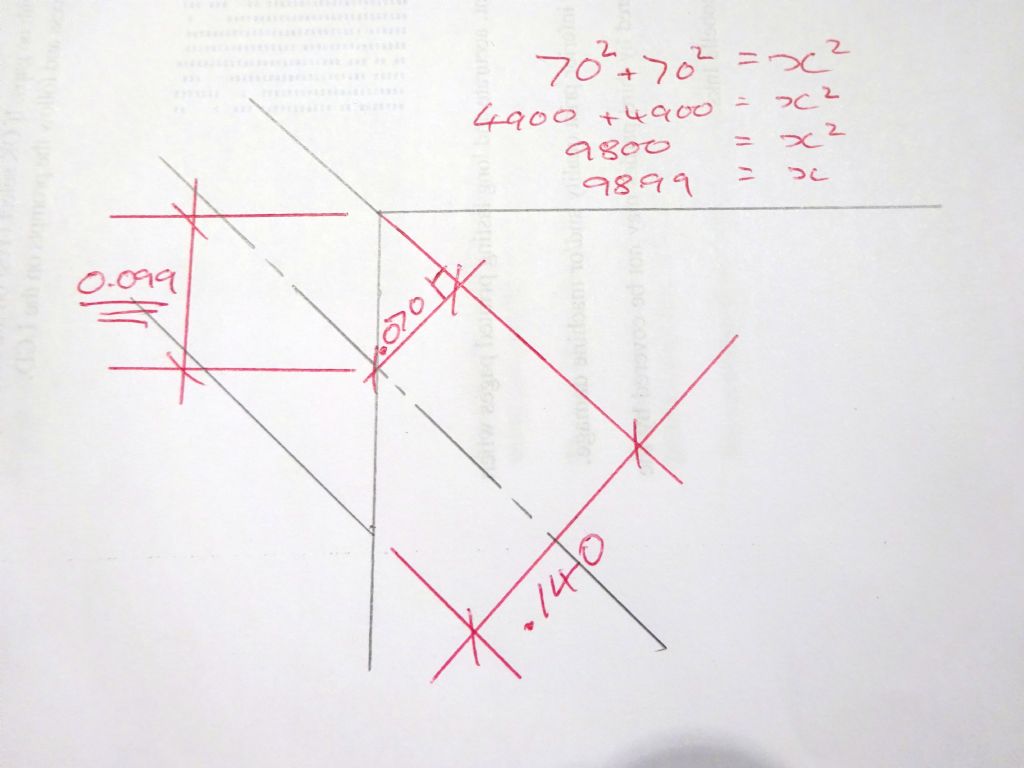

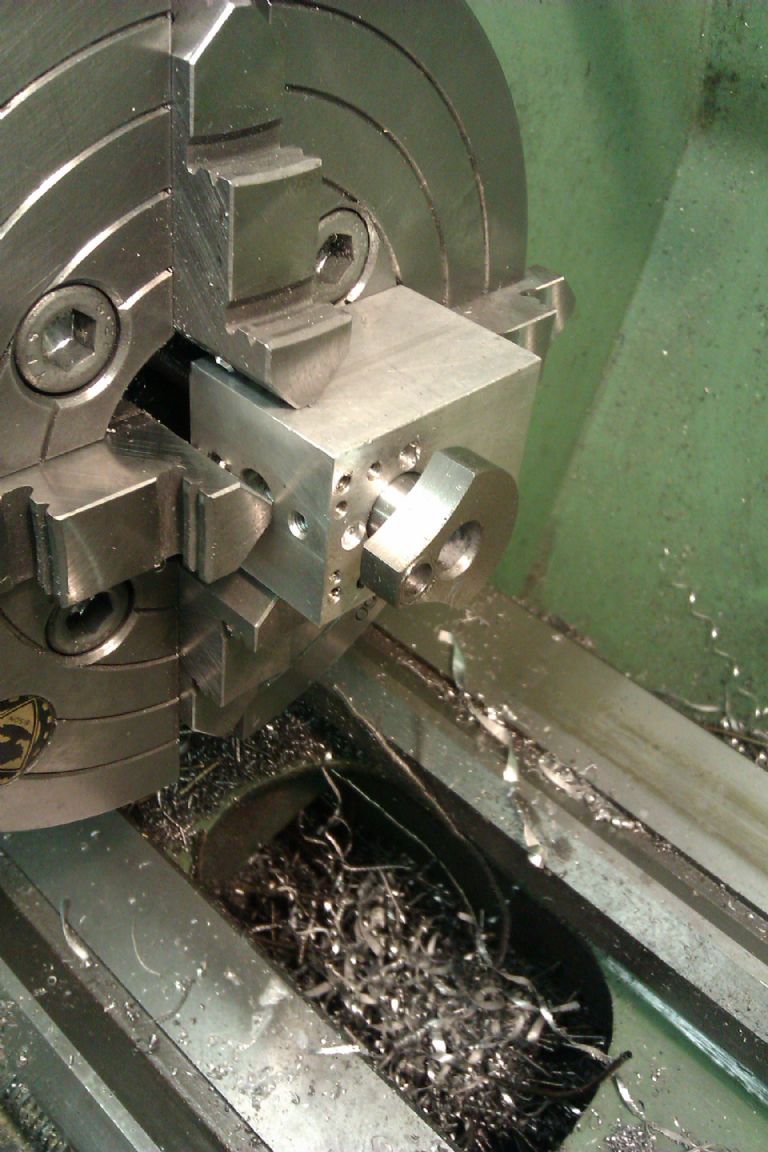

Transfer Port: No dimension is given for the top of the port where it enters the bore. Or do we have to guess that it's level with the bottom of the exhaust port? Also do we guess where to start cutting – at an angle – so as to get the cutter to just hit the corner of the flange and enter the bore just level with the exhaust port? What size cutter would I use? The photos show the set up the author used. It's a simple set-up with the liner clamped to a vee block. How did he rotate it to cut the three ports as slots?

Yes it would be nice to have height of transfers, hard to decide if top of port lines up with bottom of exhaust or passes through junction of flange and OD of liner. 3.5mm or 9/64th cutter would be about right both readily available in FC-3 type which are quite cheap. I would say they are straight slots and not cut radially, simple bit of indexing in the 3-jaw prior to milling would give the spacing

Cylinder Fins: The bottom of this component is not like the GA! If it's made to drawing then the exhaust port bottom edge is 0.08 above the bottom edge of the exhaust port in the Liner. That's half the height of the port! I have made mine to match the GA

Yes quite a difference there though the photo No24 is as per drawing

Cylinder Jacket: Having made this to drawing I found that it was well nigh impossible to get the four M3 screws holding it to the crankcase in place and then tighten them. The photos show cap head screws. I have tried all types of screws but, in the end, gave up. My solution was to machine four scallops in the top flange to allow the screws to be inserted and the hex key – with a 'ball' end' – to be used to tighten them. Of course, this means that the four long screws used to fasten the head and fins in place will need to be placed 'fore and aft' and 'across' the engine, but I don't think that will be a problem.

Can't agree with this as the photos definately show hex head bolts. but if you want to use cap heads then grind yourself up some short keys for final tightening the rest can be done with ball ended drivers

It would have been very useful to have had a Materials List in Part 1. This should have included the sizes and lengths of the screws.

I tend to just by boxes of 200 cap heads at a time and cut them to suitable length which works out a lot cheaper than buying small quantities of various lengths.

PaulG.

. But, it's not too critical.

. But, it's not too critical.