Hi all,

a bit of advice please, I hope this is the right section for this question.

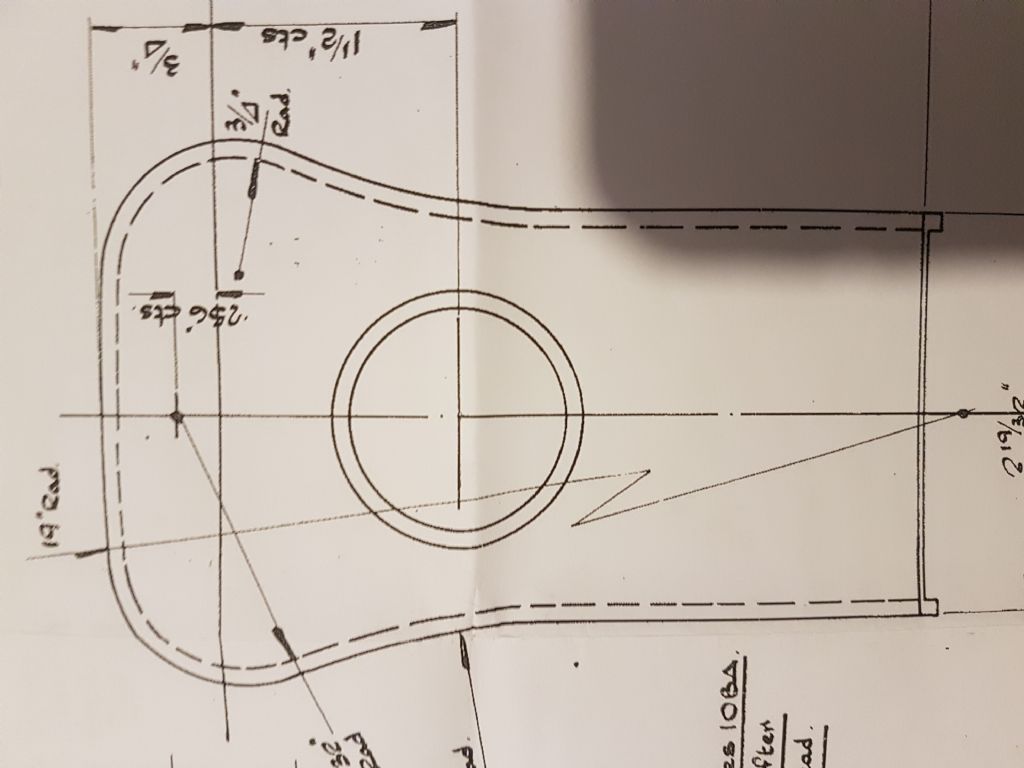

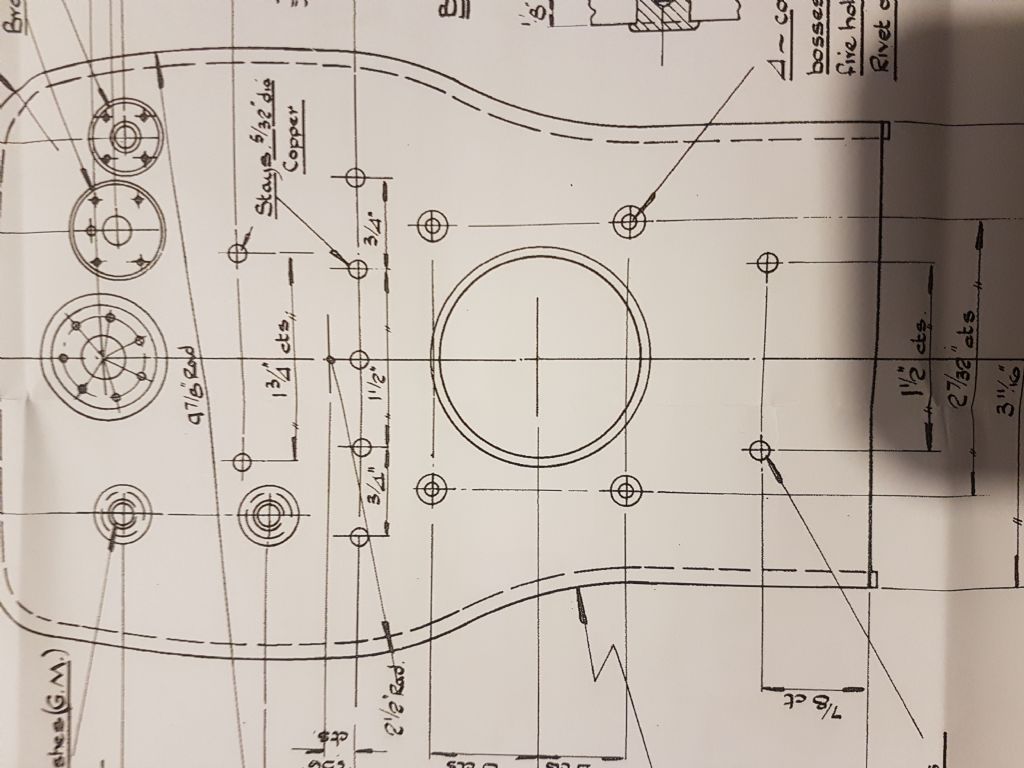

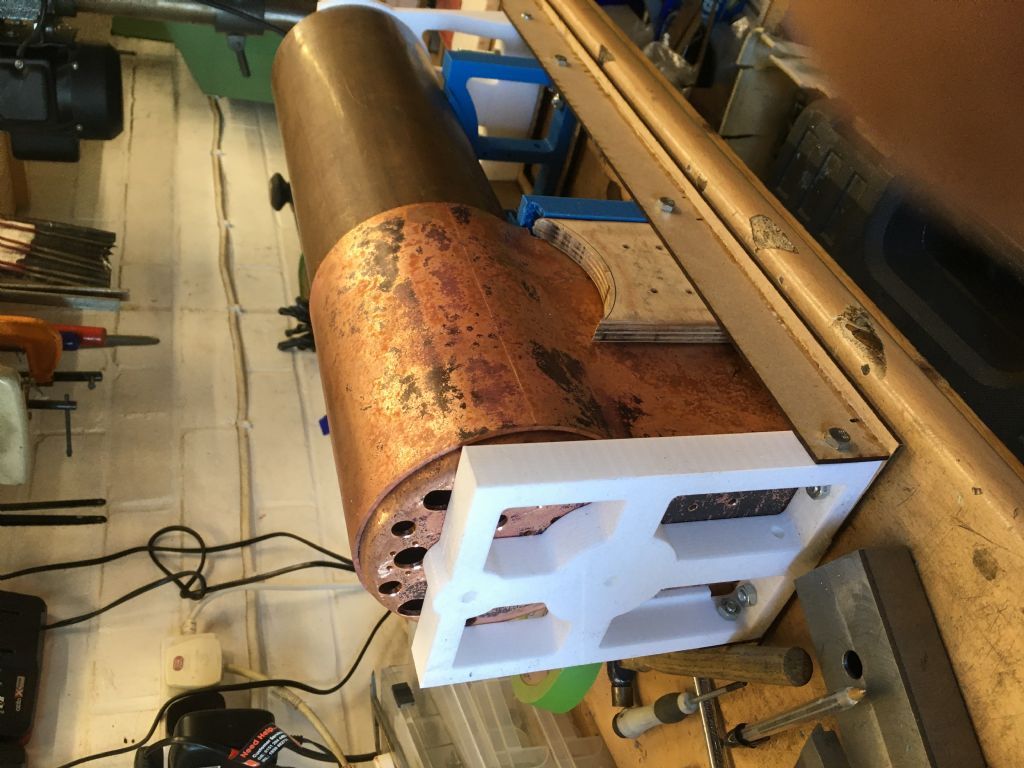

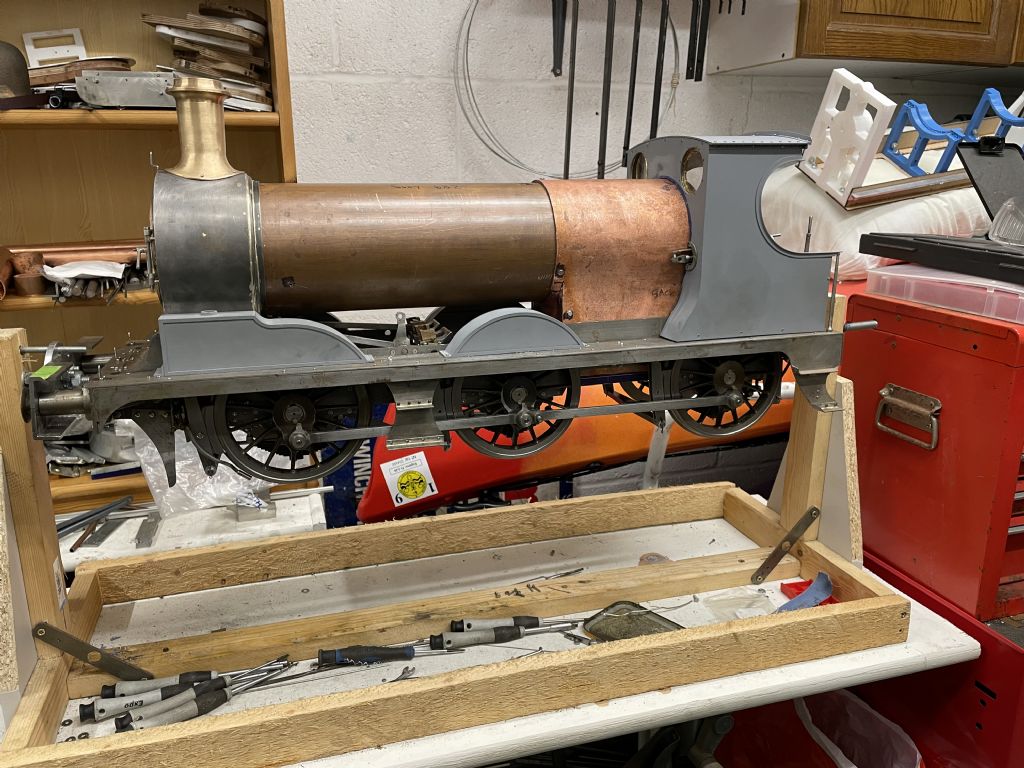

I am planning on making the Reeves 2-6-2 Prairee in 5" guage. It is a super detailed plan and copies the shape of the belpaire boiler quite well.

The tubeplate is a typical round with a flange and in such cases I have turned a steel former and followed the normal procedure of clamping the annealed plate between two plates, beating reannealing etc.

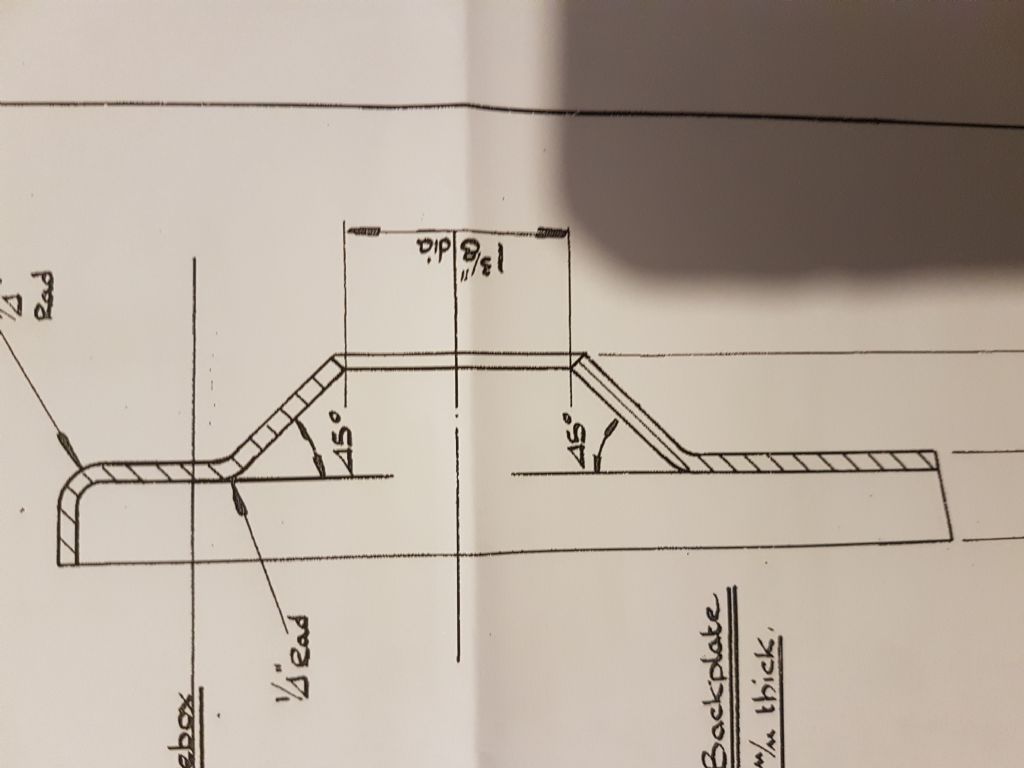

The throatplate follows typical design with a flanged hole for the taper and an opposite outside flange for the firebox wrapper. The firebox backplate and the backplate are to me unusual in that the firebox back has an outward facing flange for the firehole that mates with an outward flange on the boiller backplate, so no firehole tube.

So there are three plates that have outside flanges in one direction and flanges in the opposite direction. All these are typical belpaire shape.

I have in my mind the method of forming the plates, form the holes first and use that as a register in the clamping plate on a forming plate with a matching male section to hold the plate for forming. So any plate is going to take quite a lot of hammering. I don;t have acces to a steel bandsaw and don't fancy cutting steel formers.

What alternatives are there to steel please? I have a wood bandsaw and router, available. There is a hardwood timber yard not too far away and I have offcuts of MDF but I am doubtful if MDF will be strong/firm enought.

Thanks

Phil H1.