Back home this afternoon and have the following to report. I am so sorry if I am misleading everyone.

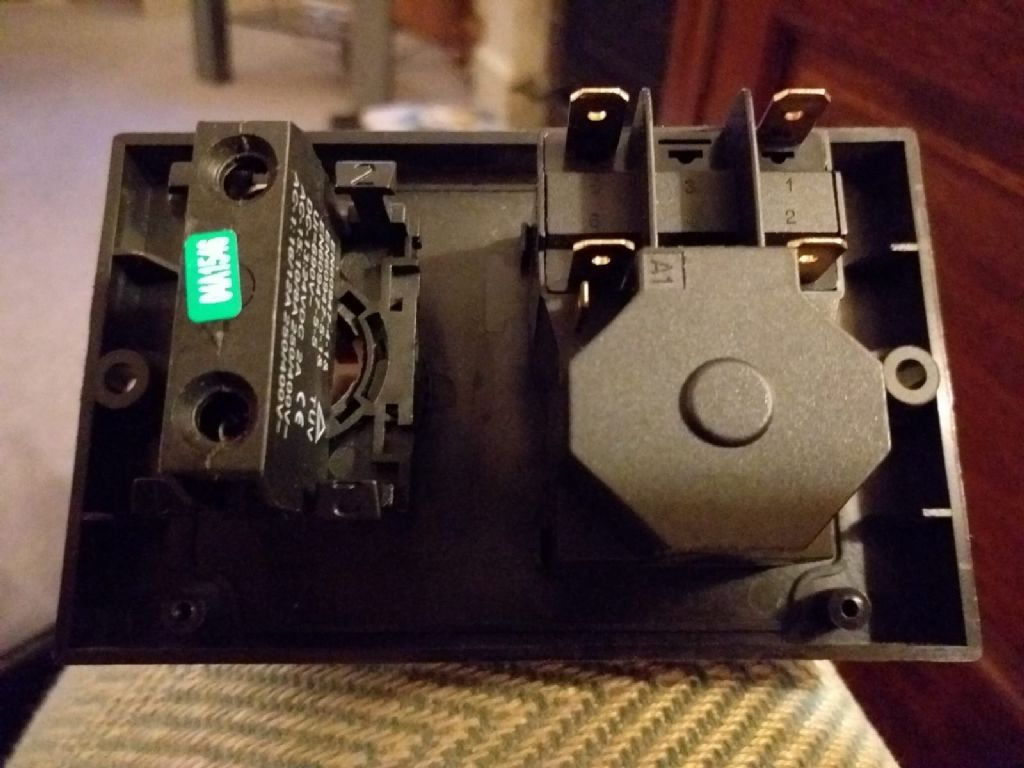

With everything as is, ie nothing disconnected or pressed in, I got the following. The digital meter reads 1. but will, when placed against terminals read various Ohms before very quickly reducing down to O. It moves very quickly so it is not easy to read the fractions to three places. If I connect the two probes together it will read 0 Ohms..

Terminals 4 to 8 – 4.22 Ohms reducing to 0. Reading can fluctuate a bit but possibly down to my technique.

3 to 7 – no reading. Meter did nothing.

2 t ditto ditto

1 to 5 ditto ditto

Across the reset button, both in and out, nothing happened in terms of physical action, that I could feel, so no reading possible.

With the coil pressed in.

Terminal 4 to 8 4.2 or 3.7 Ohms. There was variations on the start of readings.

3 to 7 no reading. Meter did nothing.

2 to 6 ditto ditto

1 to 5 ditto. ditto

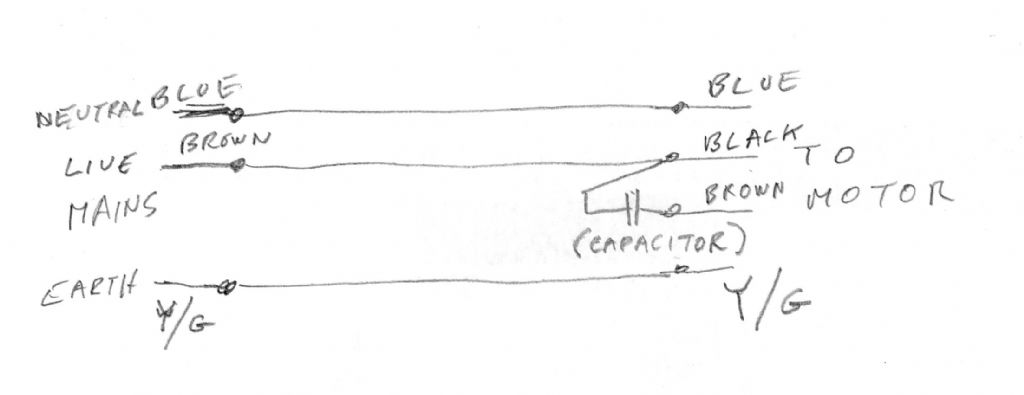

Over the capacitor terminals I got readings of 2.66 Ohms.

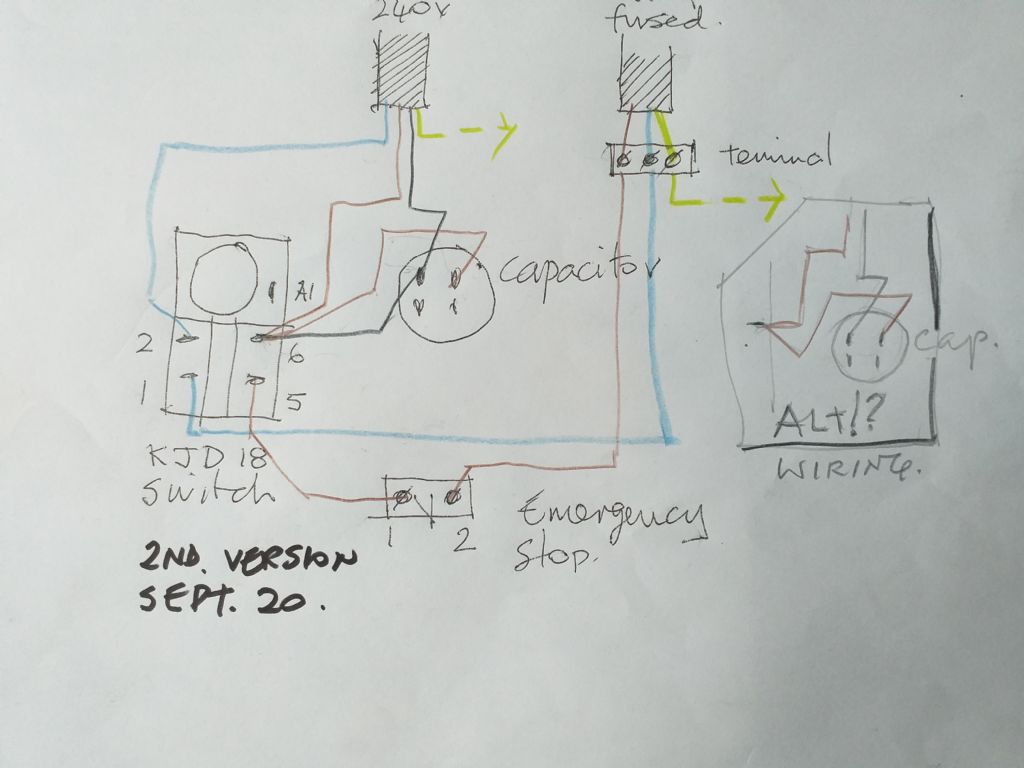

Les, you noted a NVR switch may possibly be used. If this present stuff is all too mixed up, I would be happy to go down that route; all things being equal. Looking at my saw bench which has an NVR it seems OK with the reset button wired in but no allowance of a capacitor.

I could possible separate the coil and contacts as there is very little to show connected between them, but I would need to be very careful of the return or hold back spring on the top, but cannot see where things would spill (or spring) out of.

I have ordered a replacement reset button which should be here in a few days as the 'was new' switch is definitely not right. It is not functioning even as it did last time when I tried it. Hope I being more helpful this time around and my information is less misleading.

Marsh

Marischal Ellis.