Blast-pipe – Chimney Proportions

Blast-pipe – Chimney Proportions

Home › Forums › Traction engines › Blast-pipe – Chimney Proportions

- This topic has 44 replies, 12 voices, and was last updated 23 April 2021 at 21:57 by

Nigel Graham 2.

-

AuthorPosts

-

25 March 2021 at 00:18 #535934

Nigel Graham 2

Participant@nigelgraham2Thank you very much Steve.

Yes, the World Wide Web let the "new old" version of the spread-sheet through and it's now filed among lots of other engineering spread-sheets.

You are right on my wanting a straightforward approach because the more sophisticated design techniques appear to be for locomotives, whose characteristics are much more tightly controlled, may well be quite different from those of traction-engines, and even further away for a steam-wagon like mine.

The typical traction-engine and overtype steam wagon copies the locomotive's very short exhaust pipe and often fairly high exhaust pressure; but differs by having the jet and choke inside a long and usually diverging chimney.

Whereas my wagon is likely to send very low pressure fog through a very long pipe, to a capacious locomotive-pattern smoke-box but traction-engine style tall chimney – though of relatively large-diameter and parallel above the venturi!

I am sure now though that the choke I made is far too large, but can be modified to take an inserted smaller one. The effect of a sudden step up in diameter from its exit to the chimney itself, remains to be seen. It may not actually matter, but if necessary I might be able to make a diverging liner.

'

One thing I have discovered from my collection of early engineering books is that the grate itself can be significant depending on the fuel. Among their advice (for full-size), are typical bar and gap widths for coal and coke, noticeably different.

Whether this makes much difference in miniature I do not know, but with ordinary house coal shortly to be banned, at any rate in the familiar bags at shops and filling-stations, we may have to consider the grate proportions as well as draughting, for burning processed smokeless-coal.

Or whatever we can find. (Charcoal? – Its calorific value is not much less than coke, but apparently both are lower than that of coal!)

25 March 2021 at 15:41 #536058stephen goodbody

Participant@stephengoodbody77352Glad to hear Nigel, and please keep us posted on how things work out.

I suspect that you may need to extend the liner further up the chimney from the choke, but it would also be an interesting experiment to firstly try it without and see what happens. That's an experiment I may do with the Allchin one day, when time allows, having made the liner as a stack of interlocking sections, each approximately 4 inches long, which, together with the choke, are held in place by gravity, some centering rings, and the chimney's taper. By removing the chimney from the engine and turning it upside down, out come the liner sections one-by-one followed eventually by the choke. Hence, I can reduce the length of the liner in increments of about 4 inches at a time – it would be interesting to see what effect that has on the smokebox vacuum and draught when the engine’s working hard.

As a further thought, one other feature you may want to consider is regarding the blower. My Allchin's original blower was little more than a single 3/32" diameter nozzle centered within the blast pipe and therefore jetting centrally up the chimney. This made a lot of noise but produced very little draught and would not draw sufficient air through the fire to keep our local coal burning.

During the redraughting exercise I made up a four-jet blower using removable jets, each having a much smaller hole than before, probably around 1mm if memory serves, and mounted in a circle surrounding and centered on the blast nozzle. I based the jet dimensions and the mounting PCD on the principals advocated by Laurie Lawrence in the ME magazine, probably in the early1980's. The results, coupled with the overall redraughting exercise, were dramatic – the engine now has an almost-silent blower that draws the fire superbly.

I was so pleased with the Allchin’s blower that I recreated the same arrangement on my 3” scale Hunslet loco which has very similar draughting dimensions to the Allchin. Should you be interested, there’s a video on YouTube of the Hunslet’s first steaming and you can gauge the performance of the blower, and its effectiveness on our hard-to-burn coal, from around the 12’:20’’ mark onwards.

The video and some pictures of the smokebox arrangement are under the thread "Elidir – 3 inch scale Hunslet", should you be interested, or you can get to the video directly at: https://www.youtube.com/watch?v=5FbTqFqHD-M

Finally, it would also be good to know more about what you're building – a large-scale model of a compound overtype wagon sounds intriguing!

Best regards

Steve25 March 2021 at 22:34 #536145Nigel Graham 2

Participant@nigelgraham2Howard –

Interesting! I will confess I am not an expert on the internal acoustics of i.c. engines!

I had applied the general rule that sound-speed increases with the density of the medium, but that does assume relatively stable and static conditions, such as in the open air or the sea; not in high-pressure, high-temperature gas itself travelling at very high speeds.

'

Steve –

I've had a run through the spread-sheet you sent.

Rather to my surprise due to the very different conditions, it gave diameters fairly close to my initial sums based on the cylinder bore, as in the literature I found on model-locomotives.

The results were also encouraging in chimney height, giving a minimum of about 15" – the actual one is about 21" high. I may have to make a profiled liner though, for the numbers to do their thing.

So thank you very much.

26 March 2021 at 08:15 #536165 Jon LawesParticipant@jonlawes51698

Jon LawesParticipant@jonlawes51698Julian, I am certain you wouldn't tell someone that their ignorance is bliss in person. You are coming across as quite sanctimonious, especially when on this forum and the other forums we both visit your manner is highlighted as being abrasive and yet you do not learn or improve.

You are a mine of valuable and useful information which I have learned a great deal from, please keep sharing and keeping debates going, but please try not to belittle others in the process.

27 March 2021 at 23:17 #536614Nigel Graham 2

Participant@nigelgraham2Steve –

Sorry, I ought have replied a bit more coherently but messages seem to appear on my computer a bit out of order.

I am afraid I can no longer view You-Tube videos. Something – Google I think – places massive barriers trying to force their will on me.

'

My thoughts for the blower on my wagon are as yours for your Allchin – a proper one with 4 small jets, probably adapted from Norm Norton's design for his 'Britannia'. He angled the jets to converge on the centre of the choke.

'

The wagon is a Hindley, which I chose because it was built in Dorset, I "found " it in a history-magazine, it is unusual and if I had succeeded years ago would have been the first replica. I was going to build a Foden 'C'-type but everyone has one of those. I don't blame them.

It is Hindley's "Light Delivery Van", 1 to 3 Tons, so though the model is one-third full size it is only about 5ft long by slightly under 2 ft wide; approximated to whichever advertising photograph I measured – none was exactly like another – and narrowed slightly to fit through the front door of my first house.

The firm also built a "Standard", 5-7T, an under-type with front-mounted, vertical boiler; and the "Colonial" – same thing with wider wheels and bigger water-tank for export to the Empire. They are not so pretty though!

The LDV has a patent boiler I don't think was as unique as Hindley and the Patent Office thought. It feeds wet steam through an ordinary globe-valve as regulator in a fully-exposed pipe, to an enclosed, inverted-vertical compound engine behind the boiler, and between the seats.

So it's neither under-type nor over-type but, what, … an in-between-type?

Two-speed transmission, chain-drive to the back axle differential. With no drawings, I used a general text-book on traction-engines to guide designing the axle. For the differential, I fitted a BMC front-wheel-drive car unit with a through-shaft, and replaced the crown-wheel with a motorcycle sprocket. I found years later the diff. should be on the back of one wheel, not part-way along the axle… but I won't tell anyone if you don't.

Western Steam made the boiler to the approximately-scaled outline, and I asked Helen Verrall to install superheater flues to give me the non-prototypical option. I've provided for piping the steam to and from the superheater, if I fit one, not too obviously for LBSC's old friend, Inspector Meticulous. It would be a long steam-circuit between regulator and cylinders.

One thing I have used, not shown on any of the steam-lorries' contemporary publicity, is Hindley's Patent Wheel intended to reduce vibration. It's a rather cheeky patent claim, since all it does it place a very thick wooden rim between the rose-pierced plates and smooth steel rims. If this rather speculative model actually works I may have the wheels rubbered, TE-style.

The originals did not seem to have canopies as standard, but as an optional-extra. Good God, Man, no moral fibre – they'll be wanting windscreens next! It's of traction-engine style and does improve the look of this otherwise rather Spartan vehicle.

'

The entire project, including a spectacular failure from trying to make a six-inch scale version when my experience was still only helping build the club's railway locomotive, has dragged for too many years; through my first home of my own, second then the present, third (so rebuilding my workshop each time); plus many spells of despair when at one point I nearly scrapped it! After the first attempt stalled, my girlfriend suggested I try again at a more sensible scale.

I first bolted the wheels to the chassis in my first home, a terraced cottage. I wheeled it outside like a barrow (not yet with its Ackermann steering) for roadside photographs in the sun. The Council had even kindly provided a scale-bar, two yellow lines.

A young boy asked what it was. I told him, as simply as I could as its concept was probably unknown to him.

He replied, "Cor I wish I could build something like that!"

I said something like, "Maybe one day you will!"

27 March 2021 at 23:45 #536616noel shelley

Participant@noelshelley55608Hi Nigel, it may be of little help, but if my memory serves me well such archives as there are of Hindleys was sold at weeting steam rally in 2000 as part of the effects of the late Ronald H. Clarke. I have no idea who bought them, but I will ask a man who may know. Good Luck Noel.

28 March 2021 at 00:14 #536618noel shelley

Participant@noelshelley55608Julian, Ignorance is bliss, and sometimes I'm very happy ! Thankyou and Goodnight. Noel.

30 March 2021 at 17:09 #537123stephen goodbody

Participant@stephengoodbody77352Hi Nigel,

Thanks for providing the background information on your wagon, that sounds like a fascinating project.

I'm not at all familiar with E.S Hindley and Son, but a quick search on the internet has given me some information on the company and a picture of the Light Steam Delivery Van. I certainly like the look of those patent wheels!

As an aside, and although you've probably already thought of this, there's an argument to say that, when a long superheater circuit is used, the regulator may be better placed at the hot-header end rather than the boiler end. The reasoning is that, should a slug of water get past the regulator, it will flash to steam in the superheater which may over-speed the engine. Shutting the regulator won't help as the engine will continue to run until the flashed-steam has been expended.

Conversely, the arguments against having the regulator on the hot-header side are: (a) the superheater is always at boiler pressure, decreasing its life and increasing the chances of a leak, and, (b) the regulator has to be designed to withstand a higher operating temperature than otherwise, and (c) if water was carried over, and the regulator shut, and steam prevented from escaping through the cylinders perhaps by putting the engine in mid-gear, then the unrelieved pressure trapped in the superheaters will potentially become great and may cause them to rupture. The latter concern could be resolved by installing a safety valve for the superheaters, however.

I'm not sure which side of the argument I would come down on and, as you know, most superheated railway locomotives have the regulator at the boiler-end of the superheater. Additionally, the consequences of water carryover for a model are likely less than for the full-size, and so I'm not sure that arguments based on the full-size risks would necessarily be relevant for our models in this regard. It would however be possible to do some rough calculations to estimate the volume of steam generated by a given volume of water carry-over and see if this presented a potential risk.

That said, provided the water level is properly maintained in the boiler, the risk of priming (water carry-over) is perhaps generally less for a railway locomotive than for a traction engine or wagon because the locomotive isn't subject to the bumps and jolts and quick grade-changes that is the case for a traction engine travelling along a field or road. However, when priming happens and water gets carried into the superheater the results can be extremely dramatic, as I believe was unfortunately witnessed with LNER A2 "Blue Peter" a decade or so ago.

None of the above is intended to imply a problem with your arrangement or be otherwise melodramatic, however it may be worth a look if you're still at the stage where adaptations are feasible.

Best regards

Steve

Edited By stephen goodbody on 30/03/2021 17:12:17

31 March 2021 at 23:28 #537365Nigel Graham 2

Participant@nigelgraham2Noel –

Thank you! I have a copy of Clarke's Overtype Wagon book, but that was not much help of course except as a general deign guide.

I did manage to obtain my initial information from the contemporary reviews in the trade magazine, Commercial Motor, and that usefully included broadside photos and the wheel-base.

I've also since had some help from elsewhere including some good photos whose originals were the manufacturer's own publicity shots in the factory yard.

Coming back one year from having displayed the project to date at the Model Steam Road Vehicle Rally, I detoured to the Hindley factory, in its by-then sadly derelict state, to photograph the wagon as near as I could in her ancestral home. A fence and bund prevented entry but I could still include the same buildings in the background. 'Tis all gone now. Just houses. I attracted the attention of a patrolling Police Officer, who was intrigued by it. At least it was not on double yellow lines, as when I took the first photos of its chassis (on a side-road)

'.

Stephen –

Thank you for those observations on super-heaters. The Hindley boiler has a cylindrical firebox that extends quite a way above the barrel, and with the water also above it. This, the point of its patent, was to allow working on steep hills without seriously affecting the water-level. So it gives a comparatively high steam-space that may be fairly resistant to priming.

If put a super-heater between the regulator (a simple globe-valve on the boiler top) and engine, the steam would descend about 6 inches, and negotiate a horizontal pipe maybe 10 inches long to reach the wet header. Coming back would entail a parallel route as the HP steam-chest is up near the boiler top.

I envisaged running the pipes under deep cladding, partly to hide them as they are not to prototype, but also to keep the steam warm; but we now have a considerable length of plumbing including the heater elements. What might that do?

It might store enough steam to give the regulator a rather slow response, especially to closing.

When the engine cools down, the super-heater and its pipes may trap an appreciable amount of water. Some of that water will boil on raising steam, and find its way to the engine. Naturally the drain-cocks will be open, and I intend fitting drains to the valve-chests as well as cylinders; but will this help warm the engine through or just add more water to be cleared?

Might it be sensible to add a drain-cock to the super-heater's return, where it starts its climb to the engine; possibly automatic (sprung to open when the steam pressure falls). I already thought of a discreet, manually-operated drain in the exhaust's the blast-pipe elbow, because that pipe also forms an extended U-bend.

Or am I over-thinking, and the hysteresis effects, and amounts of condensate trapped in both systems, will actually be negligible?

Reading your arguments carefully, I think the regulator being on the wet end would be the better arrangement, and the priming risk might be reduced a bit by fitting a "pepper-pot" or disc shield below the take-off point. The physical arrangement so far is just a large threaded bush, my idea being to fit into that a screwed flange with studs and nuts for the elbow into which the regulator is screwed. Hindleys seemed to have built their engines around stock pipe-fittings, and these parts are prominent.

Leading from that, the regulator being on the boiler side would also allow better disguising of the super-heater pipes. The original was not superheated. Instead, the steam exited the boiler top, turned through a large-radius bend into the valve, then passed through a horizontal and short but apparently un-lagged pipe up in the air, to the engine.

In fact it doesn't look as if the boiler was lagged either, but it's hard to tell.

'

"…. still at the stage where adaptations are feasible."

Oh, it's been at that for years!. It's one adaptation after another. There is not much on the poor thing that has not been adapted or replaced at some point, when after hours making some convoluted lump of steelwork I realise a far better way, usually much later when trying to fit the next lump in the same space!

I spotted only today, two empty rivet-holes in the smoke-box – thanks to modifying its rather basic mountings a lock-down or two ago. No idea why I put a tapped hole for a grease-cup in the fixed rear wheel's hub, though.

1 April 2021 at 00:11 #537370duncan webster 1

Participant@duncanwebster1According to the interweb, water has a density of 1000 kg/m^3, steam at 6 barg (~90psi) has a specific volume of 0.272 m^3/kg, this means a density of 3.68 kg/m^3, so just divide the volume of your pipework by 272 and you'll get the volume of water if it were all to condense

1 April 2021 at 15:02 #537482stephen goodbody

Participant@stephengoodbody77352Hi Nigel,

You've got a really interesting project there! If it were me, and given your willingness for adaptations(!), I think I'd approach this as follows:

1. Keep the regulator at the boiler end, but take precautions to prevent water ingress. The safest bet is to have the steam takeoff as high above the water level as you possibly can. Estimate the effect of hills, camber, and water-sloshing on the headspace between the water level and the steam takeoff point. Perhaps add a steam dome if there appears to be a risk of water carry-over and if that's possible in your design.

2. Add at least one low-point drain to the superheater circuit to allow condensed water to be removed after a run. This could be a simple screwed plug, or a manual valve, or an automatic snifting valve held shut under steam pressure but open to atmosphere otherwise. If using a snifting valve, make sure it's accessible for removal and maintenance.

3. Thoroughly lag the steam pipes wherever they're outside of the boiler to prevent condensation before the superheater and loss of all that superheat after. Even if the pipes are under the boiler cleading, if the superheater did its job then the surrounding temperature will still be much less than the temperature of the steam within.

4. If possible, configure the setup to allow the superheater to be bypassed in the future. Assuming there is a shorter and more direct route from the regulator to the cylinders, it would be interesting to determine if the superheater provides any real benefit given the amount of external piping and complexity it involves. If the benefit is marginal, then you can choose to eliminate the superheater circuit and save some maintenance hassle in the future!

I hope the above is somewhat helpful Nigel, but won't be in any way offended should you disagree with or ignore some or all of it! I would certainly like to hear how things go however, so please keep us posted.

Best regards

Steve

Edited By stephen goodbody on 01/04/2021 15:04:39

1 April 2021 at 17:29 #537508Howard Lewis

Participant@howardlewis46836Purely some asides.

Locomotives often had the regulator in the dome, but were probably not superheated. Certainly, later locos had what our North American cousins called Front End Throttles, implying that the Regulator was in the smokebox with the superheater header, so probably downstream of the superheater tubes . Which would be exposed to the hot gases, all the time. Possibly more damaging if the regulator were pre superheater, reducing the throughput of steam to absorb the heat. Locomen never seemed to worry about condensation in the superheater tubes when lighting up from cold. And I've never heard it mentioned on the steam locos on the Romney Hythe and Dymchurch Railway., almost all of which which I am sure are superheated

One other thought, poor steaming may not be caused by poor draughting in the smokebox and chimney. If the grate cannot acess enough air, the fire will not burn brightly.

Remember 71000 Duke of Gloucester. Apparently a poor steamer until someone just tore large holes into the ashpan, short circuiting the dampers, and admitting extra air.

I believe that some Great Western Firemen used the dampers as an additional means of controlling steam production, but could be wrong.

You already have the boiler, but the Sentinel vertical boiler had a good reputation as a steam raiser., so maybe a study of the Sentinel boilers (and firebox and draughting ) may be of some help..

Howard (Smileys – grrrr )

Edited By Howard Lewis on 01/04/2021 17:30:24

1 April 2021 at 23:20 #537567Nigel Graham 2

Participant@nigelgraham2Duncan –

Thank you for the formulae – would be interesting to examine the numbers though thinking about it, I suspect the amount of condensate would be negligible compared to what happens in the cold cylinders anyway on first opening the regulator.

'

Steve –

Thank you for those ideas. It should be quite easy to experiment as you say, because the prototype steam feed to the engine was a short pipe with flanged joints, up on top of the boiler and meeting the engine only just behind the driver's left shoulder. The way my project's grown has given a wide annular channel between the boiler-barrel and smoke-box wall. I have fitted that with three interpenetrations – one for the blower, and two for the super-heater, blanked-off simply with screws.

The steam take-off is right at the top of the boiler, which itself was designed to keep the water-level fairly stable when driving up and down hills. (Such as the one rising from their factory, in a steep-sided valley!) I think mid-glass on my boiler is about 4 inches below the boiler-top.

A manufacturer's photo of a sample wagon awaiting its platform, shows the take-off was a swept bend rising a few inches above the flange – about an inch on the model – before turning horizontal to meet the regulator. From that valve, a short level pipe in the air above the cylinders reached a displacement-lubricator and lever-operated device I interpret as a starting-valve, on the HP slide-valve chest.

The route is so direct that with discreet lagging, it may indeed not make much difference to fit a superheater. The 4 flues are rather small so the elements probably won't be more than 6mm bore.

A super-heater drain need be no more than a screwed plug, though a little plug- or drilled-screw valve won't fall into the grass, and can be used when the engine is resting hot. (It's not only workshops that have those kleptomaniacal elves.)

Incidentally I found a neat little cock in a come-in-handy box, for the injector water – I think it was originally a motorcycle petrol-tank valve, of 90º-turn plug rather than slide form. That, its stainless-steel extension-spindle, guide-bracket and handle, all fit neatly on a vertical length of steel angle simply screwed to the chassis.

As on other components, where possible I use tapped holes to avoid barely-accessible nuts and washers.

'

Willingness to adapt things? Not sure about that!

It's very frustrating, wasting a lot of metal, time and electricity.

Resignation would be more accurate, as I found when I drew (in TurboCAD) a basic layout plan earlier this evening. I may need move the steering-column, gear-box and drop-link … and it would fall right onto one of the boiler-mountings I have just spent several days painfully and slowly making and fitting.

Is there a demand for surplus chassis bolt-holes, used once only by a careful driller?

I need too, make a better steering-wheel and replace the temporary, second-hand worm and wheel a bit too small for the purpose. That drawing showed the new, larger and stronger steering-wheel I was going to make, for easier control, would be too over-scale. Ah. Ummm…. Actually, while typing that, I think I recall seeing that solved on another model steam-lorry, by clipping the larger version to the scale one, for driving.

'

Howard –

" Locomotives often had the regulator in the dome, but were probably not superheated. "

I think most locos had dome-mounted regulators and from very early on, but I am not sure when superheating became normal.

A few overtype steam-wagons had super-heaters, too, but that was rare practice; and as good as unknown on traction-engines. One or two steam-wagons were fitted with exhaust-heaters though, to disperse the vapour less obviously – I think that was to be less alarming to the still-important horse-power.

I' m sure you're right about condensation in super-heaters probably being negligible, but while they tend to be self-draining on a locomotive – into the cylinders, one on my wagon would form a big " U-bend " .

I have yet to design the circular grate and ashpan, but yes, I will be careful to allow for plenty of air-flow with the damper(s) open. I considered using a " Rosebud " grate, based on design sums kindly given me by another builder; but I've noticed these buds don't seem to have blossomed much lately.

'

I'd not heard problem that of 71000, but were the original air-openings behind the dampers, too small then?

Not only the GWR firemen using the dampers to control the fire. This is what the full-size "words and music" tell us:

" The dampers …. can be used to good effect to control the rate of burning under all conditions when the regulator is closed. There can be no hard and fast rule as to which dampers should be used when the regulator is open on the journey; this depends on the judgement of the Fireman. "

That is quoted from my copy – an original too – of the Handbook For Railway Steam Locomotive Enginemen, pub. British Transport Commission, 1957.

So the BTC was not just stirring films of GPO mail-trains "crossing the border" – and we've no excuse!

2 April 2021 at 15:04 #537646

2 April 2021 at 15:04 #537646Howard Lewis

Participant@howardlewis46836Nigel G 2

You prompted me to look up my 1957 copy (For some reason, numbered 398 ). On page 53 it says,

"Regulator valves of the vertical,slide, horizontal slide, balanced circular and double beat types as well the multiple valve type in the superheater header are in common use on British Railways"

This suggests that multiple valve types were the ones fitted in the superheater header.

As you say, with a vertical boiler, a superheater could be a U bend, likely to to collect condensation at the lowest point, unless it could be placed as a horizontal coil at the top of the boiler.

The boilers for the Sentinel DG, Super and S type waggons used a double concentric coil, in this way, for superheating, avoiding any U bends.

Howard

2 April 2021 at 17:52 #537687Nigel Graham 2

Participant@nigelgraham2Sorry Howard –

I should have been a bit clearer.

My steam-wagon boiler is not vertical but a modified locomotive-type, with a cylindrical firebox that extends well above the short, horizontal barrel whose centre-line is on chassis level. Think of a big T-piece standing on its side.

It is placed in the chassis so the firebox is between and just ahead of the crew seats, and the steam outlet and regulator is on the top of the outer firebox, with the regulator hand-wheel to the left of the steering-wheel.

The vertical engine is just behind the boiler, with its steam inlet nearly at regulator height. In full size, these connections were all a bit above above the seated driver's elbow height.

So the superheater, if I fit one, and most of its associated pipes, would be horizontal, but down nearer footplate level, significantly lower than the regulator and the engine inlet.

Therefore the " U-tube " is most of the steam circuit – a long, level section between the vertical parts about 6 inches deep, of the flow and return pipes.

'

Intriguing: my copy of the engineman's bible is stamped 526 on the inside cover, and bears further rubber-stamps: New England (was that a running shed?), the name M.S. Houghton – then on the title-page, J.S.Houghton stamped very neatly between the lines "British Transport Commission" and the title itself.

Father and son, maybe, when it was still common for sons to follow Dad and Great^x-Grandad into the same trade?

I've just spotted too, that the succinct Foreword is by a Mr. R.F. Harvey, described as Chief Operating and Motive Power Officer. I though the " Chief xxxxx Officer " form was something that had fallen into the Mississippi River hence North Atlantic Drift to our shores in the last couple of decades or so!

I have an NTET-facsimile of a fairly equivalent book published in the commercial days of steam-road vehicles, and use it as a design-guide. I re-discovered recently I have an original copy of it, its thin paper now so fragile that one thinks of ancient mss from the Scriptorium. Only in English, not Latin – and showing the old "uses the same steam twice " canard about compound engines was common even among Edwardian professional traction-engine drivers ! Its inside cover is rubber-stamped L.D.W.H. Education [&] Training, but the flyleaf carries Jack Stevenson, 8 Rosemary Ave in very faint pencil, and the number 516 also in pencil, corrected to 517 in ink.

According to a tiny sticker, LDWH's / Jack's book cost me a princely £1 from Bookpress Bookshop.

I wonder who those three men were; where and when they worked steam-engines for a hard, grubby living often in very rough conditions, not in a creative hobby?

Edited By Nigel Graham 2 on 02/04/2021 17:58:02

3 April 2021 at 13:28 #537826Howard Lewis

Participant@howardlewis46836Hi Nigel,

Yes, New England was a LNER (probably ex Great Northern ) Running Shed in Peterborough . Large enough to have its own breakdown crane, which occasionally went to the assistance of others.

There is an area in the city still known as New England, and the rows of old houses are known as New England Cottages.

There is no Rosemary Avenue in Peterborough, but there is one in Market Deeping which is a few mile north.

So now you know where one of the previous readers lived!

Howard

Edited By Howard Lewis on 03/04/2021 13:29:32

3 April 2021 at 21:00 #537922Nigel Graham 2

Participant@nigelgraham2Thank you Howard1

It is rather nice to know where one's older possessions came from; but Goodness knows where the book was, before I found it.

''

Had a day off from engineering today – now that the rules have relaxed enough for small groups to meet outdoors, the cave-finding project in which I am involved, resumed today.

Progress on the wagon in the last week or so has focussed on fitting the boiler to the chassis and discovering that the off-side one of the newly-made, Brackets, Boiler-mounting, Mark Two won't allow me to move the steering column forwards the inch I think it has to go… (it fouled the drop-arm… but if I move that too far forwards on the same alignment its ball-joint nut hits the off-side front wheel spring-hanger. And so it goes on.) So I went at it with drill, hacksaw and file, to give me an idea what Brkt, Blr-Mtg Mk3 (OS) needs look like.

I've also put the rivets in the two holes left in the smoke-box door ring by a modification I made nearly a year ago. I must have forgotten at the time and spotted them only a few days ago. They wouldn't have helped the draughting!

22 April 2021 at 22:43 #541143Nigel Graham 2

Participant@nigelgraham2Stephen –

I have now started making the new choke, based on your spread-sheet. I'd broken off from that for a while to revise the boiler's mounting brackets on the chassis.

I'm making the choke in two parts, and have machined the longer, exit end, but it is only 2 inches tall and ends abruptly at about 1.5" dia, opening inside the 2.75" dia chimney. I think the theoretical continuation by that 1:6 rule is at least 9" (the outer chimney, to scale, is about 20" tall) .

I'll go with it for now and see what happens on test. If I need make an extension to the cone I'll probably have to roll it, if I can.

I've to make the converging part yet, but because the choke is in two parts I'll probably screw together via a flange on the main section, have paused to make an adjustable alignment-tool whose central stem also has a spigot turned to fit the blast-nozzle's calculated diameter.

'

Two weeks ago I had a very bad fall at home, and damaged something in my leg badly enough to make me somewhat immobile. This has interrupted work on the wagon, and I did not touch it for nearly a week. As it is I cannot stand for long, such as for a long machining operation.

23 April 2021 at 21:00 #541284stephen goodbody

Participant@stephengoodbody77352Hi Nigel,

Sorry to hear about your fall, and hope that you're soon back on your feet in the workshop.

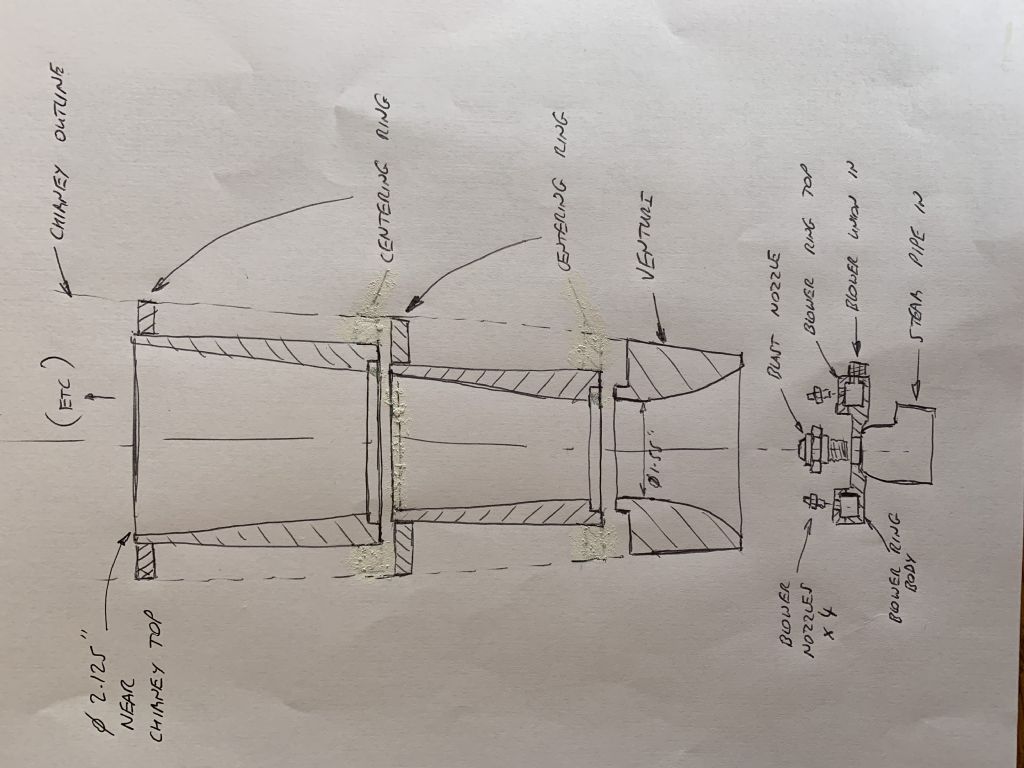

If it helps, here's a sketch of how I made the sectional liner:

It seems to me that, if your choke section is short and opens immediately into a much larger diameter chimney, you run the risk that, when the engine is working harder and the exhaust jet sharpens (ie, the jet's cone angle decreases), the exhaust jet may not fill the chimney. In that case the choke probably won't provide much benefit.

While it would be an interesting experiment, if I were you I'd plan things so that you can readily extend the liner at a later date.

Best regards

Steve23 April 2021 at 21:57 #541293Nigel Graham 2

Participant@nigelgraham2Thank you Steve.

I've applied, at the surgery's advice, for physiotherapy. I planned to complete the alignment-tool today but after a very fraught and painful expedition to the shops only a couple of hundred yards away this morning, I did not go into the workshop at all today. I was booked to go on a local geological field-trip on Sunday, but that's out of the question now.

'

Yes, I do have something like your drawing in mind, and I have made the choke itself so an extension can be bolted to it.

The limit on a taper length I can turn, short of making some form of taper-running attachment, is the 3" compound-slide travel on the Harrison lathe. However, using sections as you have also has the advantage of material economy by stepping up the stock diameters.

I found the best way to make the venturi is in two parts joined on the choke line, and to bore the billet through to choke diameter, then taper-bore diverging towards the chuck. That means I can see when the tool is approaching the choke itself, leaving a very small land inside it. The other end looked after itself, with due care not to run the boring-tool into the chuck of course as the diameter hidden from me increased .

I cut two wide grooves into the outside of the venturi, with a small land in the middle for its location in the chimney saddle. This gives a bolting-flange each end, and cuts the weight down. The smoke-box, a piece of 8" seamless-steel pipe, is heavy enough as it is.

One detail I am adding is making the outer chimney detachable to aid transporting and storing the vehicle; by flanges probably in prototypical way, at least to general traction-engine practice. I would have to make any liner similarly removable.

'

It's occurred to me to make a long blast-nozzle threaded to screw into the pipe so its height can be adjusted. Alternatively, a simple telescopic tube locked by grub-screws.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Traction engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Kennet Tool and Cutter Grinder

Started by:

bankcottage15 in: Manual machine tools

- 3

- 5

-

23 May 2025 at 17:53

bankcottage15

-

Hints and tips

Started by:

larry phelan 1 in: Hints And Tips for model engineers

- 3

- 3

-

23 May 2025 at 17:47

Bo’sun

-

What Did You Do Today 2025

1

2

…

4

5

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 29

- 121

-

23 May 2025 at 17:35

Diogenes

-

Building Bernard Tekippe’s Precision Regulator

1

2

…

4

5

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 14

- 101

-

23 May 2025 at 17:34

Chris Raynerd 2

-

Which to buy; Warco GH Universal vs Weiss VM32H Mill

Started by:

thisdesignedthat in: Manual machine tools

- 8

- 15

-

23 May 2025 at 16:55

JasonB

JasonB

-

2inch Fowler plans

Started by:

bob53page in: Traction engines

- 5

- 7

-

23 May 2025 at 16:55

Dave Halford

Dave Halford

-

Is a tool & cutter grinder worth having?

1

2

3

Started by:

Brian H in: General Questions

- 40

- 61

-

23 May 2025 at 15:15

Tony Pratt 1

-

“What about the drains in Finchley?”

Started by:

Plasma in: The Tea Room

- 8

- 16

-

23 May 2025 at 15:07

Plasma

-

Drunk driver broke my workshop!

Started by:

stew 1 in: The Tea Room

- 13

- 24

-

23 May 2025 at 14:53

Nicholas Farr

Nicholas Farr

-

‘STIFF’ Compound Slide

Started by:

kevian64 in: Beginners questions

- 9

- 9

-

23 May 2025 at 13:47

Michael Gilligan

Michael Gilligan

-

Pinnacle milling machine

Started by:

acklam65 in: Help and Assistance! (Offered or Wanted)

- 5

- 5

-

23 May 2025 at 13:14

Howard Lewis

-

Wyvern Engine

Started by:

Dave C in: Help and Assistance! (Offered or Wanted)

- 6

- 10

-

23 May 2025 at 11:54

Dave C

-

Quill Mounted DTI Holder?

Started by:

Bo’sun in: Workshop Tools and Tooling

- 3

- 3

-

23 May 2025 at 10:54

Robin

-

Contact Details for Matt Jeffrey

Started by:

Neil Wyatt

in: General Questions

Neil Wyatt

in: General Questions

- 1

- 1

-

23 May 2025 at 10:50

Neil Wyatt

Neil Wyatt

-

Stuart Twin Victoria (Princess Royal) Mill Engine

1

2

…

50

51

Started by:

Dr_GMJN in: Work In Progress and completed items

- 34

- 1,272

-

23 May 2025 at 09:21

bernard towers

-

Amadeal VM25L Uneven Motor Brush Wear

1

2

Started by:

Richard Kirkman 1 in: Help and Assistance! (Offered or Wanted)

- 13

- 29

-

23 May 2025 at 09:11

Richard Kirkman 1

-

Not unexpected, but is it predictable ?

1

2

Started by:

Michael Gilligan

in: 3D Printers and 3D Printing

Michael Gilligan

in: 3D Printers and 3D Printing

- 10

- 38

-

23 May 2025 at 07:27

Michael Gilligan

Michael Gilligan

-

Boxford Cud or ML7

1

2

Started by:

Trevor Howley in: General Questions

- 17

- 31

-

22 May 2025 at 20:13

Bazyle

Bazyle

-

Countersinking carbon fibre sheet with my Sieg CNC Mill

Started by:

Sarah F in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 7

- 18

-

22 May 2025 at 19:06

Sarah F

-

Kennedy Hexacut machine hacksaw

1

2

Started by:

Leo F Byrne 1 in: Help and Assistance! (Offered or Wanted)

- 18

- 46

-

22 May 2025 at 17:56

Waggonerman

-

Suitable fuel for boll aero engine

Started by:

half whit in: I/C Engines

- 7

- 14

-

22 May 2025 at 13:39

KEITH BEAUMONT

KEITH BEAUMONT

-

Help and advice please

Started by:

acklam65 in: Beginners questions

- 7

- 12

-

22 May 2025 at 10:47

Pete

-

Colchester Chipmaster Clutch question

Started by:

Peter_H in: Manual machine tools

- 2

- 4

-

22 May 2025 at 10:43

Pete

-

Tungsten Contact Points

Started by:

Durhambuilder in: I/C Engines

- 11

- 21

-

22 May 2025 at 09:53

Graham Meek

-

Midlands Model Engineering Exhibition, Thursday 16th to Sunday 19th October 2025

Started by:

Meridienne Exhibitions 1 in: Exhibitions, Shows and Club Events

- 1

- 1

-

22 May 2025 at 09:26

Meridienne Exhibitions 1

-

Kennet Tool and Cutter Grinder

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Kennet Tool and Cutter Grinder

- Hints and tips

- What Did You Do Today 2025

- Building Bernard Tekippe’s Precision Regulator

- Which to buy; Warco GH Universal vs Weiss VM32H Mill

- 2inch Fowler plans

- Is a tool & cutter grinder worth having?

- “What about the drains in Finchley?”

- Drunk driver broke my workshop!

- ‘STIFF’ Compound Slide