Thank you all for your feedback again!

Bazyle – Yeah I tried that and neither seemed particularly worse than the other. The locking-effect seemed cumulative and proportional to the additional stiffness.

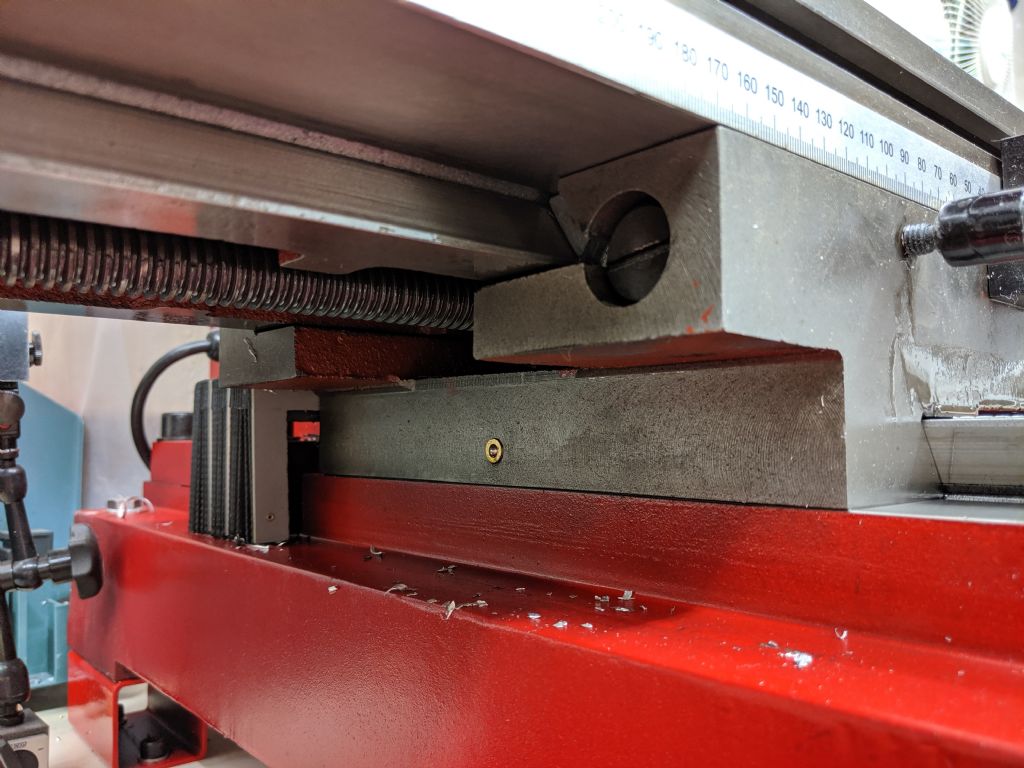

Andrew – I can only infer the Y-axis feedscrew is parallel because there's no binding when the X-axis locks aren't tightened (I'm not sure how to accurately measure the perpendicularity of the screw). I would expect binding all the time if it was a screw-related issue. I did try adjusting the feed handle's nut last year and it did make a difference to the overall tightness and also seemed to affect the backlash. I think it's in a position of reasonable compromise at the moment for general use, it's just the additional tightness from the X-axis locks that's been a problem.

Barrie – Thank you, I do think it has to be flex in the machine and possibly over-tightening of the locks. Before late last year I hadn't milled since Uni and used some Bridgeport-looking machines where things stayed where they were put. I guess even on the SX4 it's all about reducing the cutting forces to within the machines ability (had an issue with up-cutters being pulled out of the ER collet while trying to cut slots last year because I couldn't get enough clamping force on them vs the force from the cut I was making).

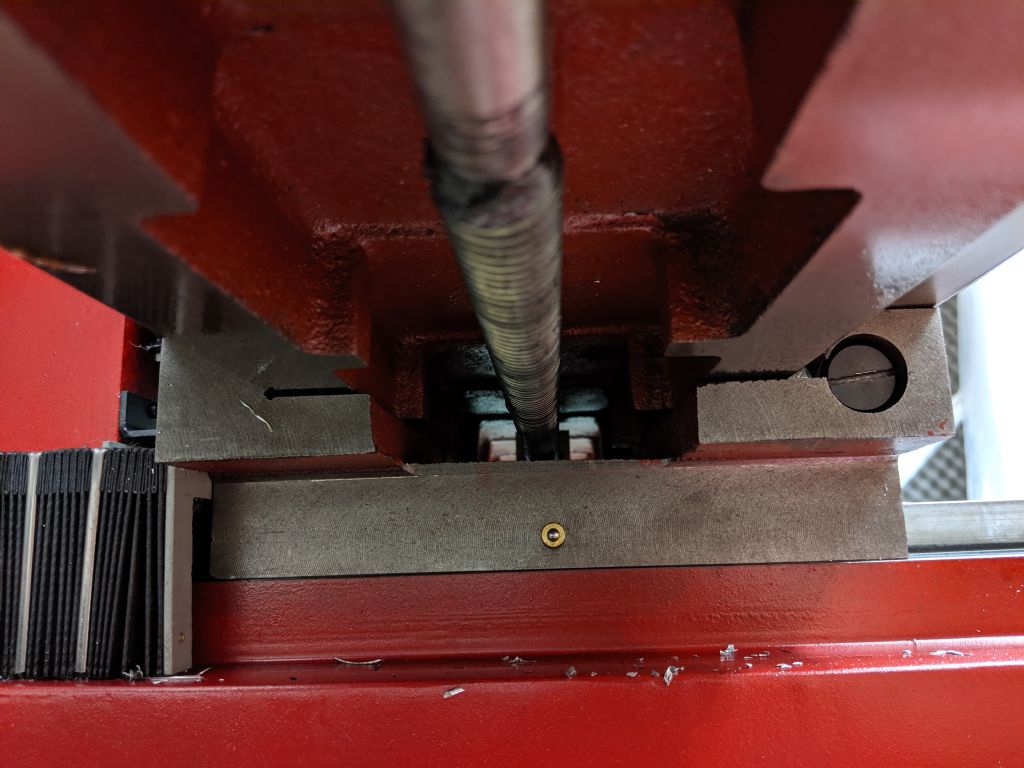

Dave – I think I see what you're saying but I think the handle of the lock bent more than the screw so I'd expect minimal damage on the inside. I've had the locking screws out and they seem OK. (they're such a bad design for where they're placed)

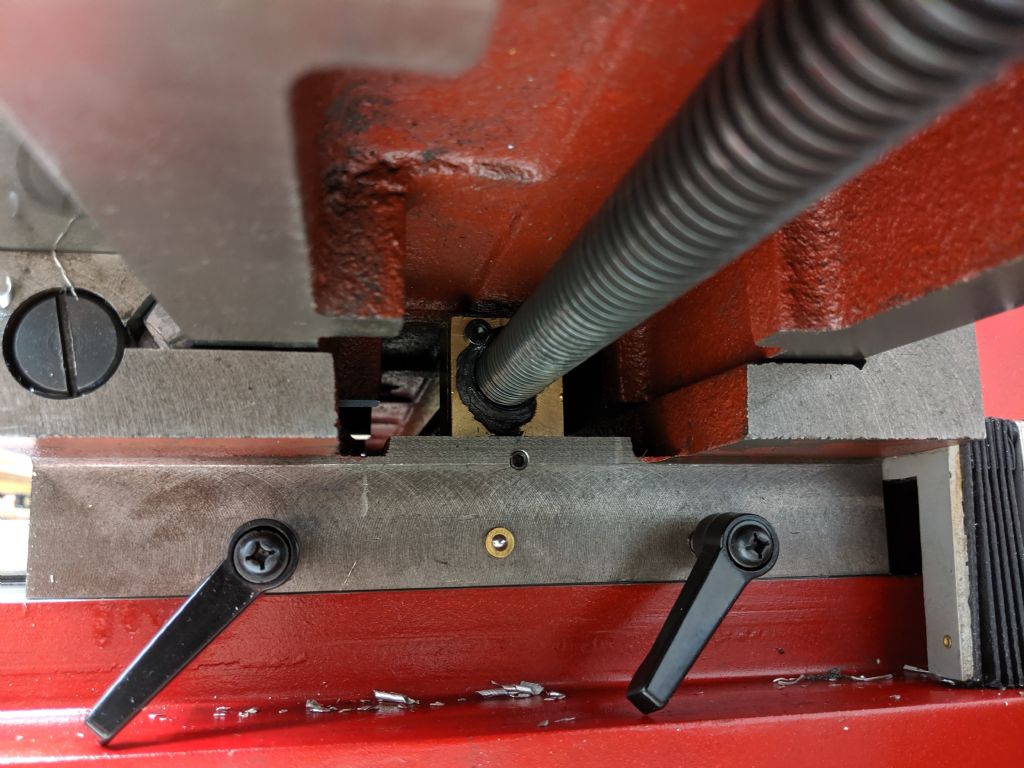

Jason – I am beginning to suspect a lack of oil has certainly exacerbated the problem! I had been applying oil directly to the ways because I'd not realised those ball bearings were oil-points.

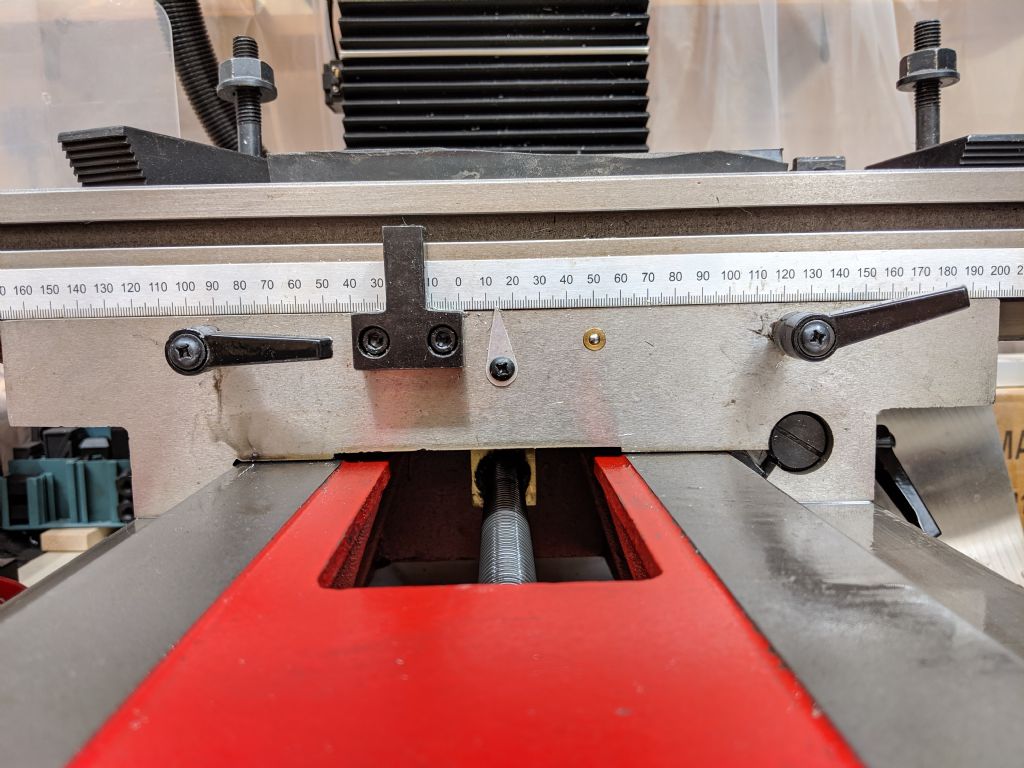

Is there any chance that the gibs are slightly different thicknesses? One of the locking screws goes in further than the other. I'm using Fuchs Renolin CLP 68 Gear Oil on the ways. It's some I bought to use on my CNC routers linear rails and ballscrew (but I'm now wondering if it's a little too thin for something as slow-moving as a milling machine?).

Robert – I should probably take a look at the jibs as they've been mentioned a few times (and one locking screw goes in further than the other) but being so new to milling I was concerned about re-setting up the machine afterwards.

Matthew

Matthew Sugden.