Here is an old technique for operating a mill, following the above suggestions and taming backlash for the X axis.

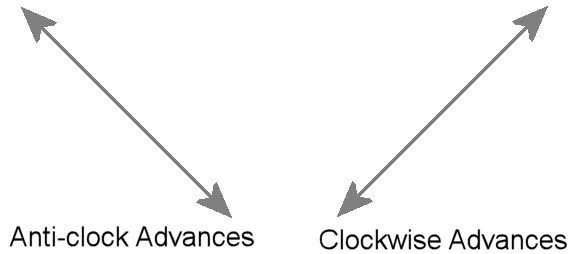

Starting with the RH (right handwheel), turn it CW (clockwise) and move the table sufficient distance to take up the backlash. Lock the table when you reach where you want your X-axis zero.. Set your handwheel index to zero. Now coming from the left side, move to the LH (left side) handwheel (x-axis table lock still tightened). Turn the LH handwheel CW until it takes up the backlash. Set the LH handwheel index to zero.

Unlock the table lock.

You can now get back to zero when moving from the right, so long as you move from the right with the right side handwheel. Same concept when approaching from the left using the LH handwheel. Just don't reset the index settings. This takes some unlearning or a locking screw on the index wheel (which explains one reason why some machines use a thumbscrew instead of just friction for the index)

You can check your settings with a DTI/or dial indicator or a fixed pointer, by measuring against a block on the table or vise. To verify, fix the precision block (1-2-3?) at your zero point. Move the table (with its clamped block) toward the DTI and zero the DTI at your index dial zero line. Repeat the move and see how close you get.

Since you have a precision block, you can check the other handwheel index coming from the opposite direction (plus/minus the width/thickness of the block). Some ops tape or quick clamp a vertical piece of precise thickness to the edge of the block to measure against from the opposite direction.

If you forget and change an index dial, you can go to the opposite wheel and go back to your original zero point.

A solution for keeping track of "turns" is to use a magnet-equipped ruler. Position the ruler under a fixed pointer when you are at your zero set point (established as above). To move 100mm, you can make your move and watch the pointer vs the ruler. When you get close to your goal, you use the readings on the index dial. Moves from the right, use the right wheel. Moves from the left use the left wheel.

GHT and others suggest all moves should measure from the same starting (zero point), to reduce accumulated errors. Takes some practice to change bad habits.

Old school tech used a movable ruler locked on the front/side of the table, with a fixed pointer pointing at the ruler. Using a magnet equipped ruler is an update of this concept AND the magnetic ruler can be used anywhere, X, Y or Z axis.

Improvements or clarifications welcomed.

Paul

Edited By Paul Fallert on 18/09/2020 15:54:08

old mart.