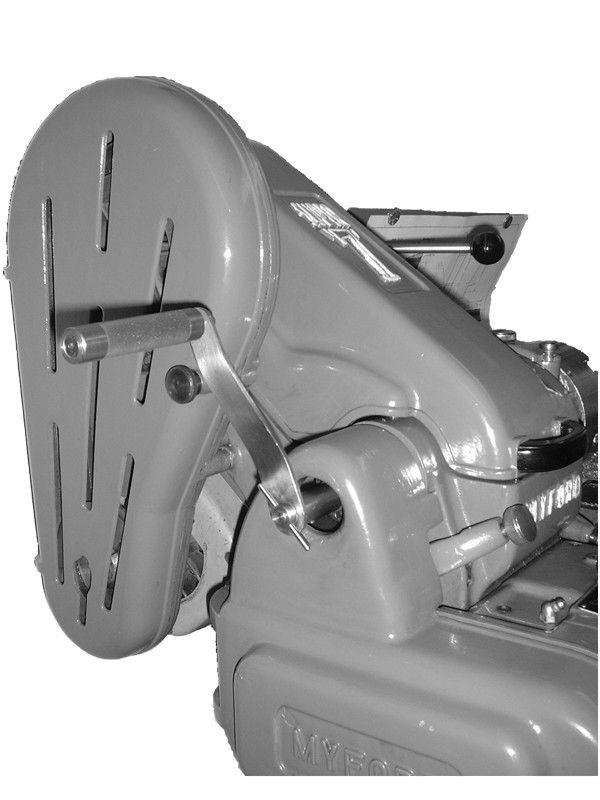

I'm sure this should be a simple one: I'm making the Hemingway Myford Spindle Driving Handle (mandrel handle) and I need to bend two angles on the 1/8" thick mild steel bar for the crank (around 7/8" wide). The bend radius is not critical, though the two angles need to be 'reasonably' accurate to ensure the two ends of the bar end up parallel (like a Z, though with obtuse not acute angles). I have already shaped the piece and drilled the two holes.

The tools I normally use to bend (much thinner) sheet steel are:

- A large Record engineer's vice

- Two long pieces of 5mm angle iron

- A handled Sykes Pickavant tool made from tool steel that is used for bashing onto without bruising the work

- A big hammer!

I also have a MAPP gas torch that may be useful to soften the steel prior to bending. If I use this, does the bend area need to be heated to red hot or would the steel soften enough to bend it at a lower heat?

I assume that many people on this forum have done a similar thing with 1/8" sheet steel. I'd be very grateful for any advice you have for me, including how I might apply the necessary leverage.

As always, many thanks in anticipation,

Mike

Edited By Mike Donnerstag on 12/05/2020 22:21:57

Henry Brown.