Hi all,

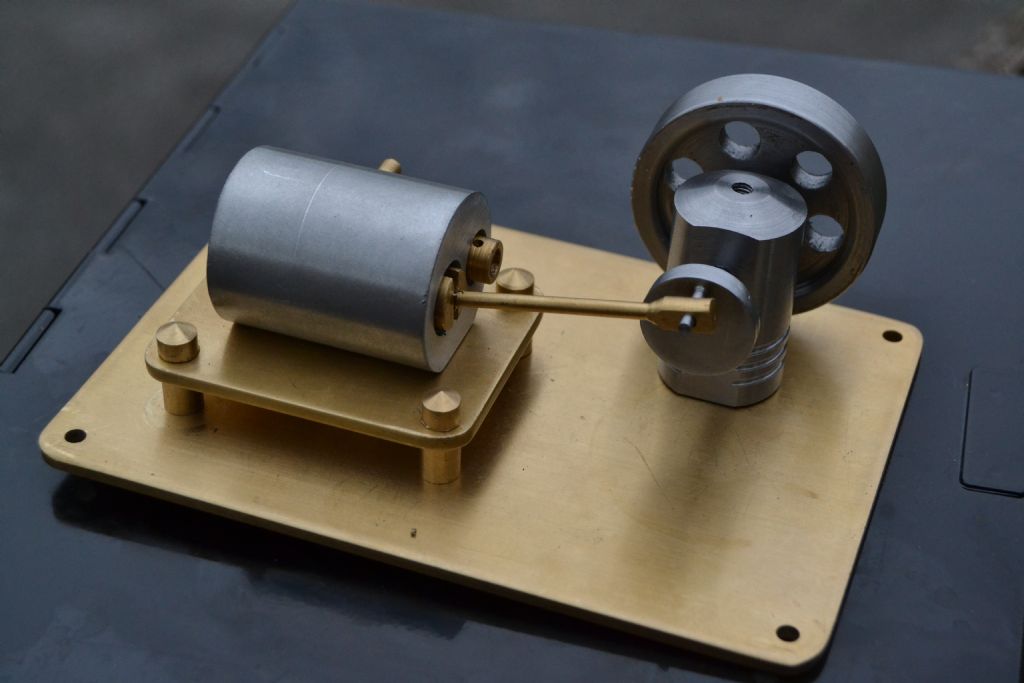

As a complete beginner to this hobby and someone who has only owned a lathe a few weeks I feel I'm now getting past the 'swarf making stage' and have decided to try and built my first steam engine.

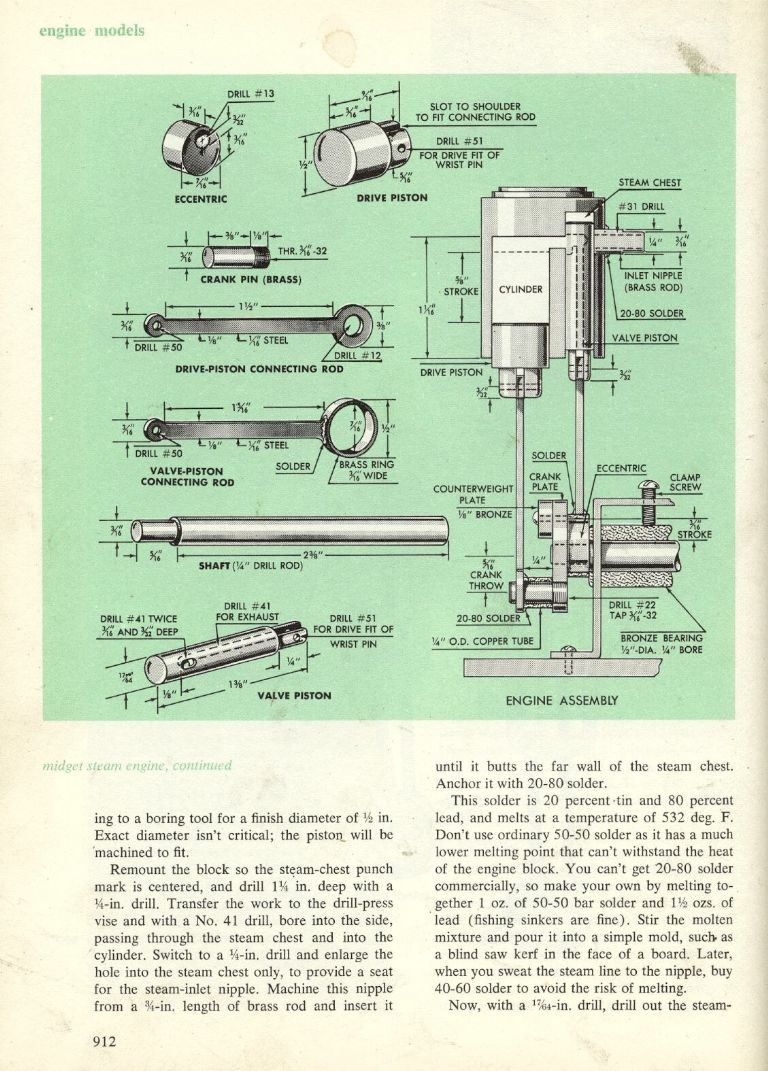

I've decided to have a go at this :-

**LINK**

If it proves to be beyond my skill level I'll put it to one side for a few weeks till I have the necessary skills and/or tools to do the job.

The plans are in imperial but I've decided to work in metric (my lathe and measuring equipment are all metric) so whilst I am working to the basic design the measurements are flexible and I'll modify / embellish it as I go along.

As I say I am a complete beginner so if people want to offer me advice or tell me better ways of doing things I'm more than happy to listen.

Here goes :-

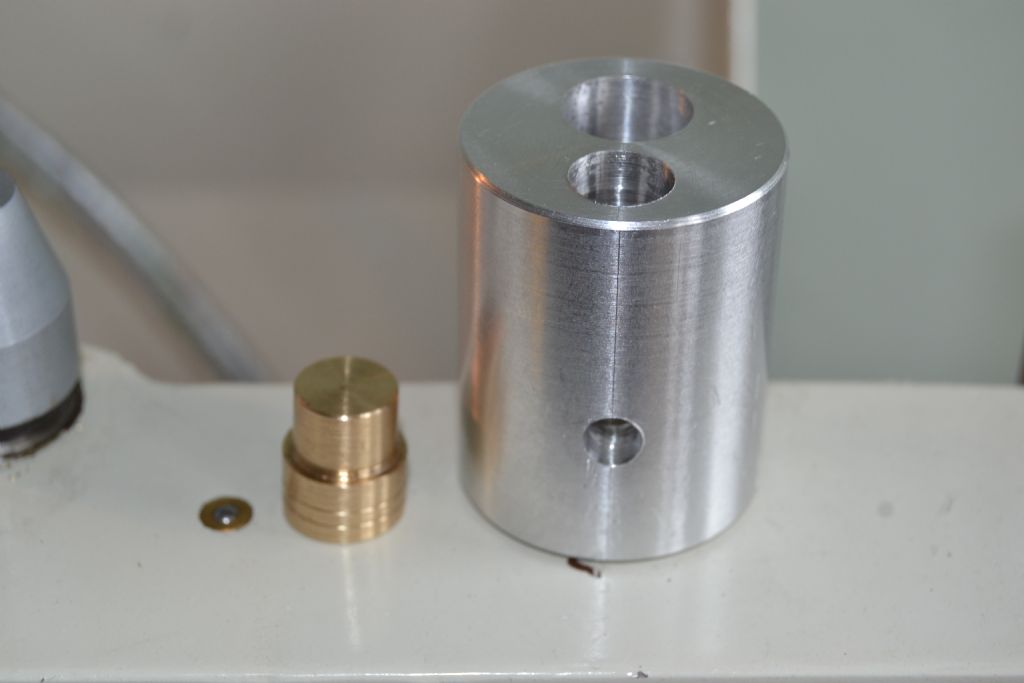

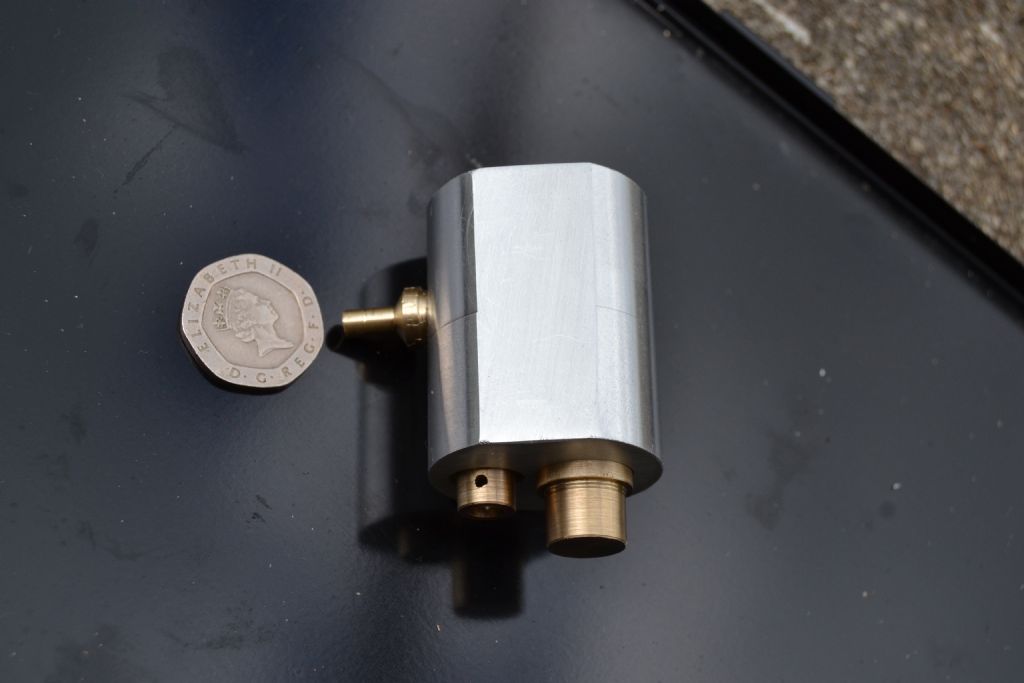

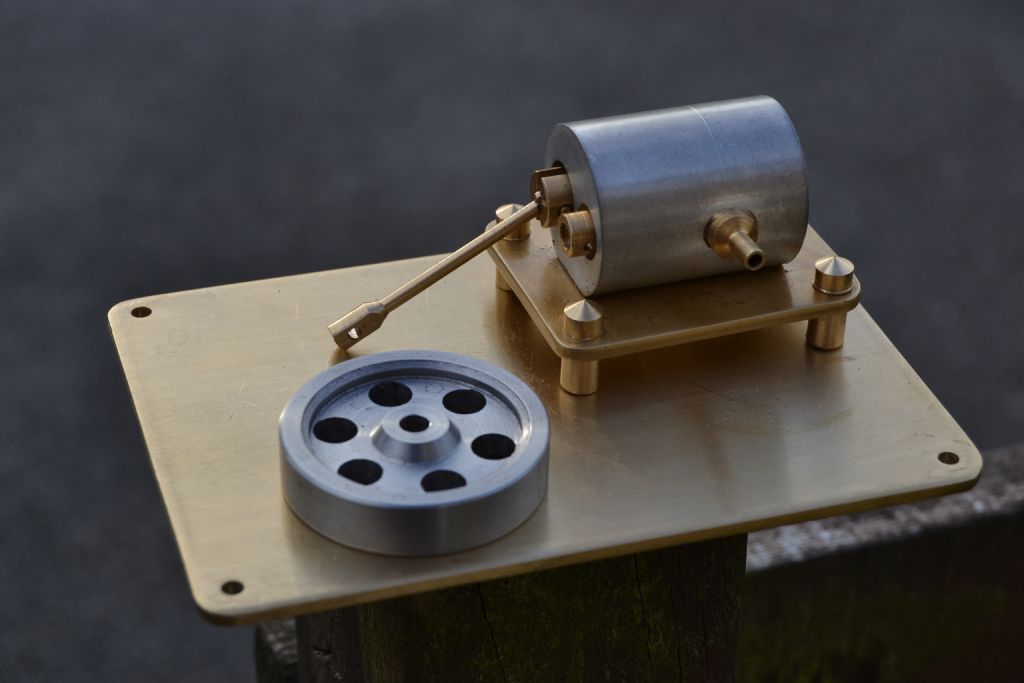

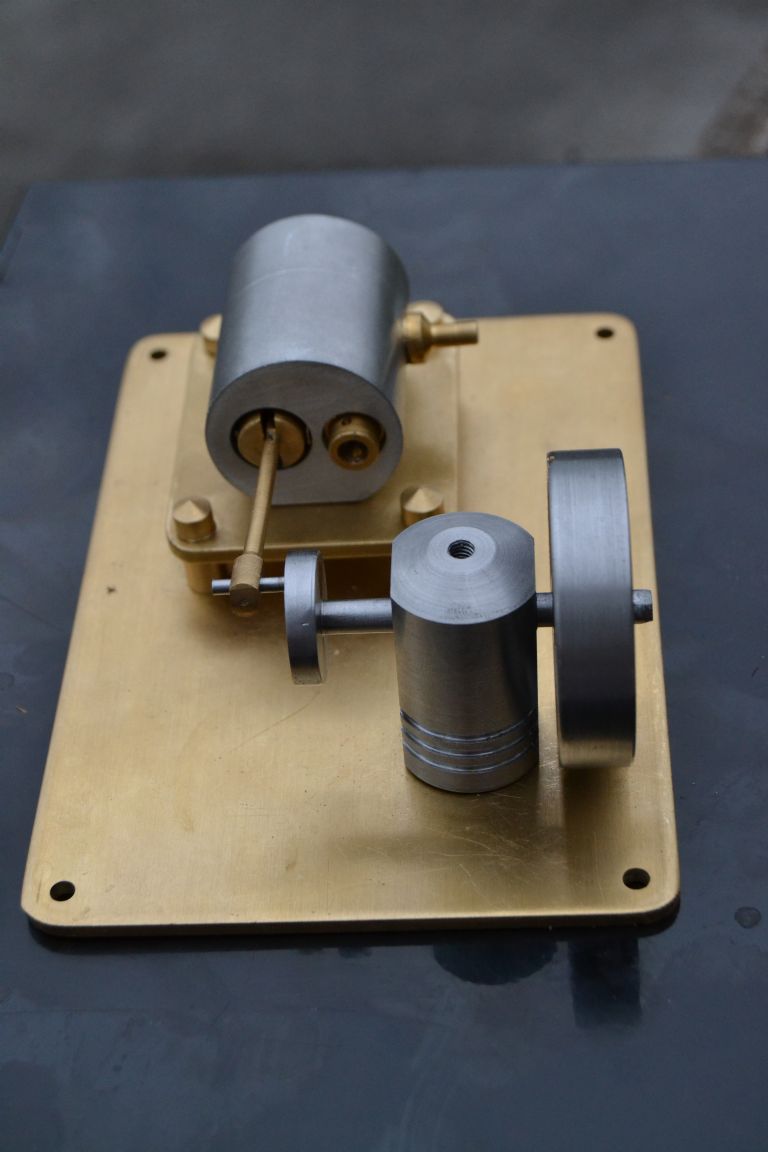

Firstly I decided to machine the cylinder block / steam chest, I didn't have a piece of brass big enough to hand so I settled for aluminium (It's unlikely the engine will ever see live steam so I figured aluminium will do for compressed air).

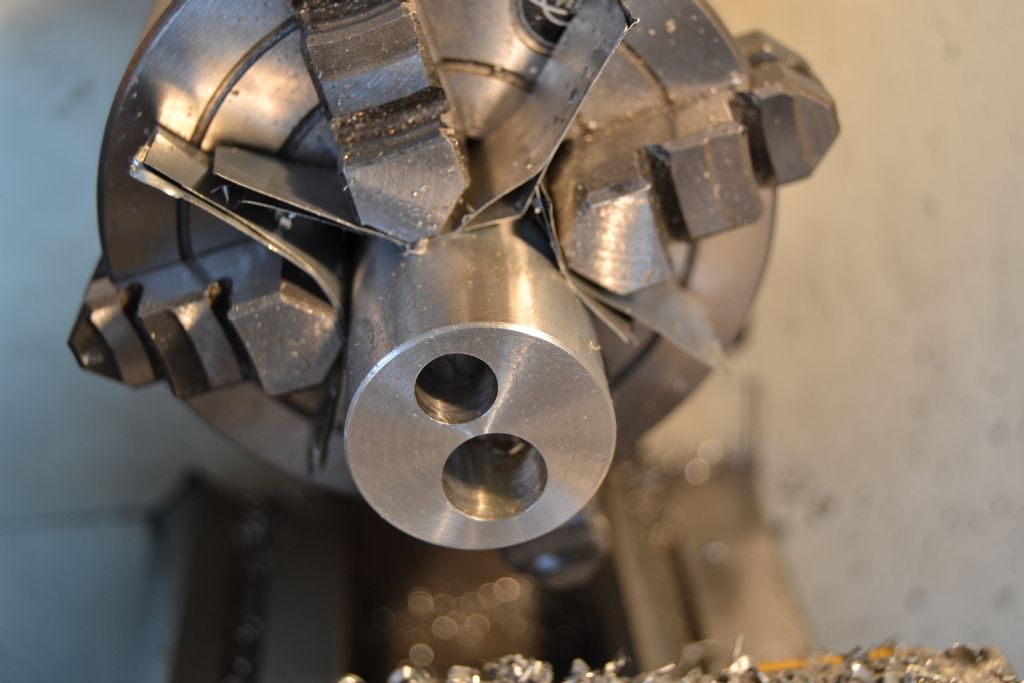

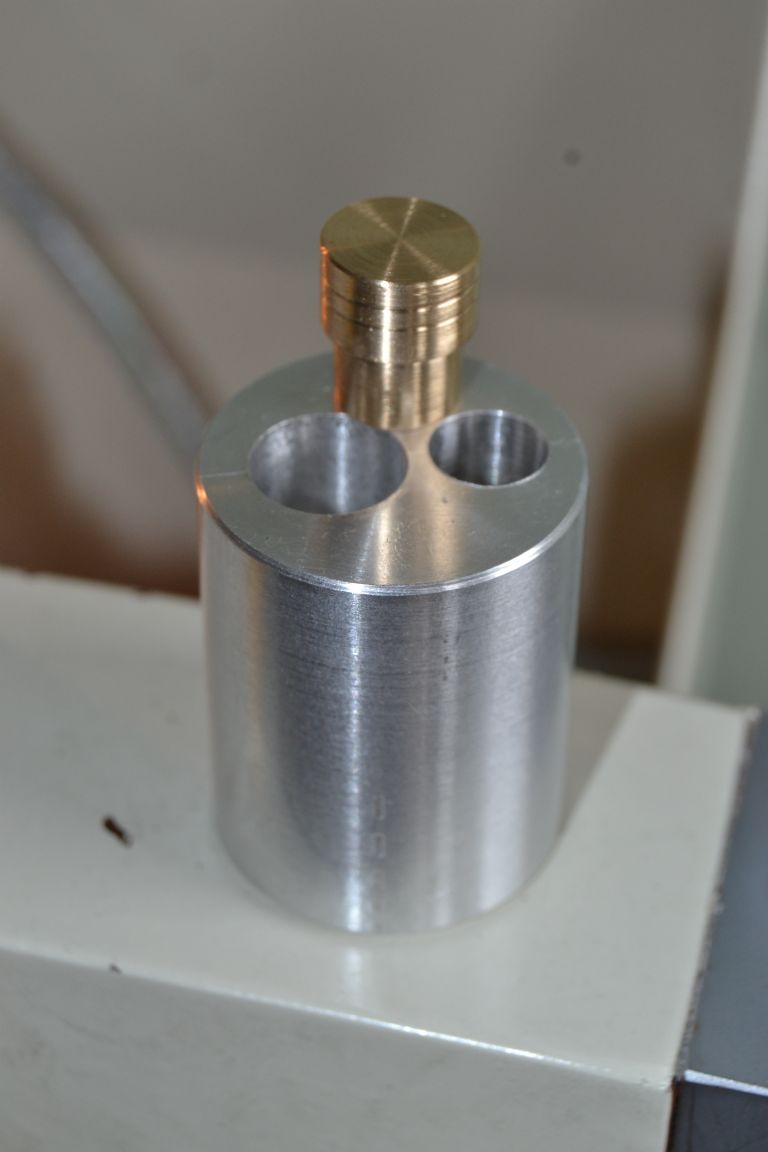

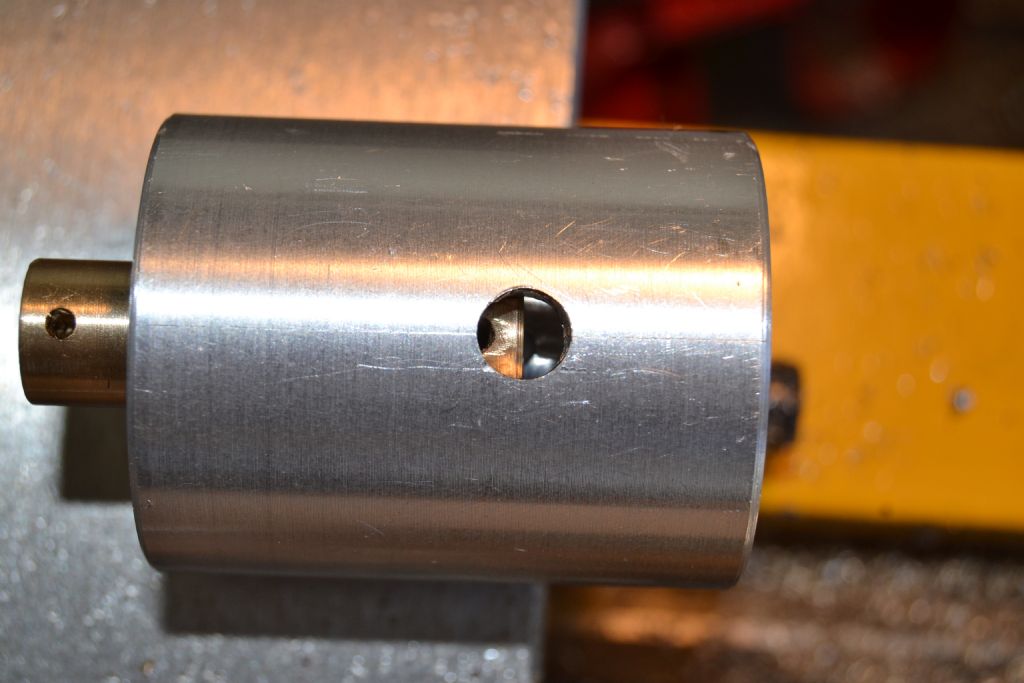

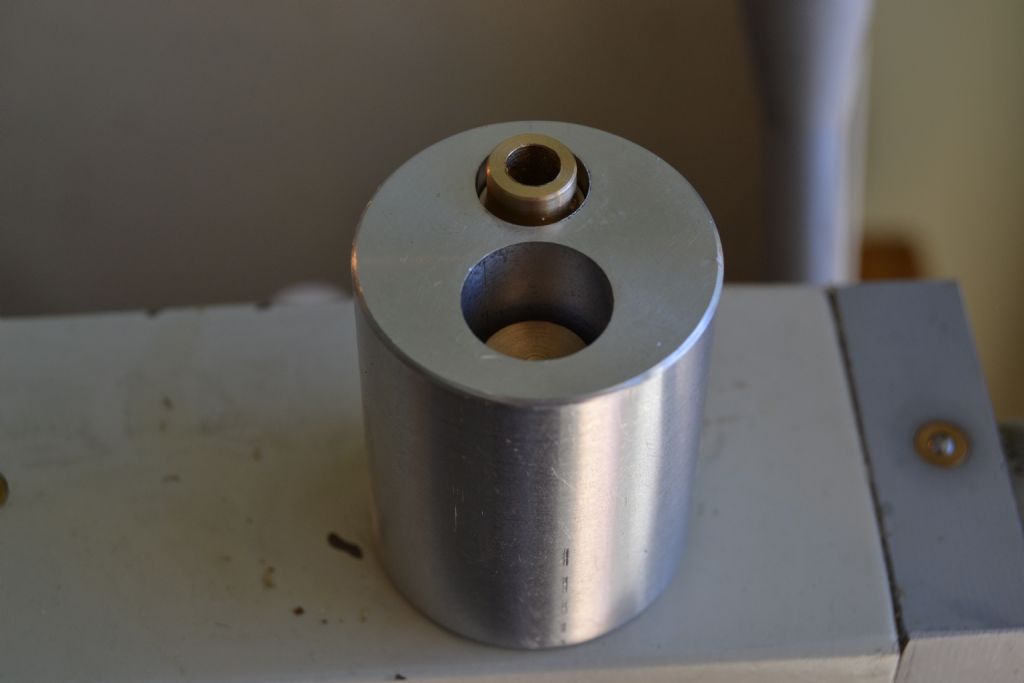

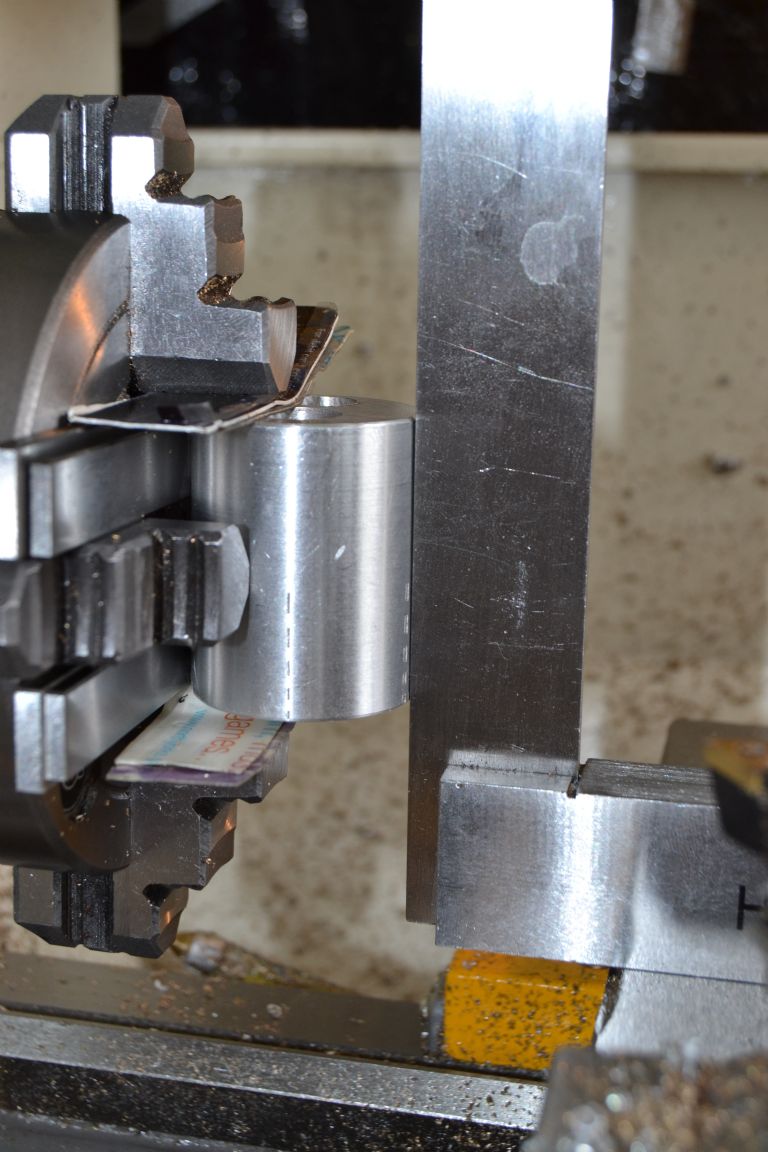

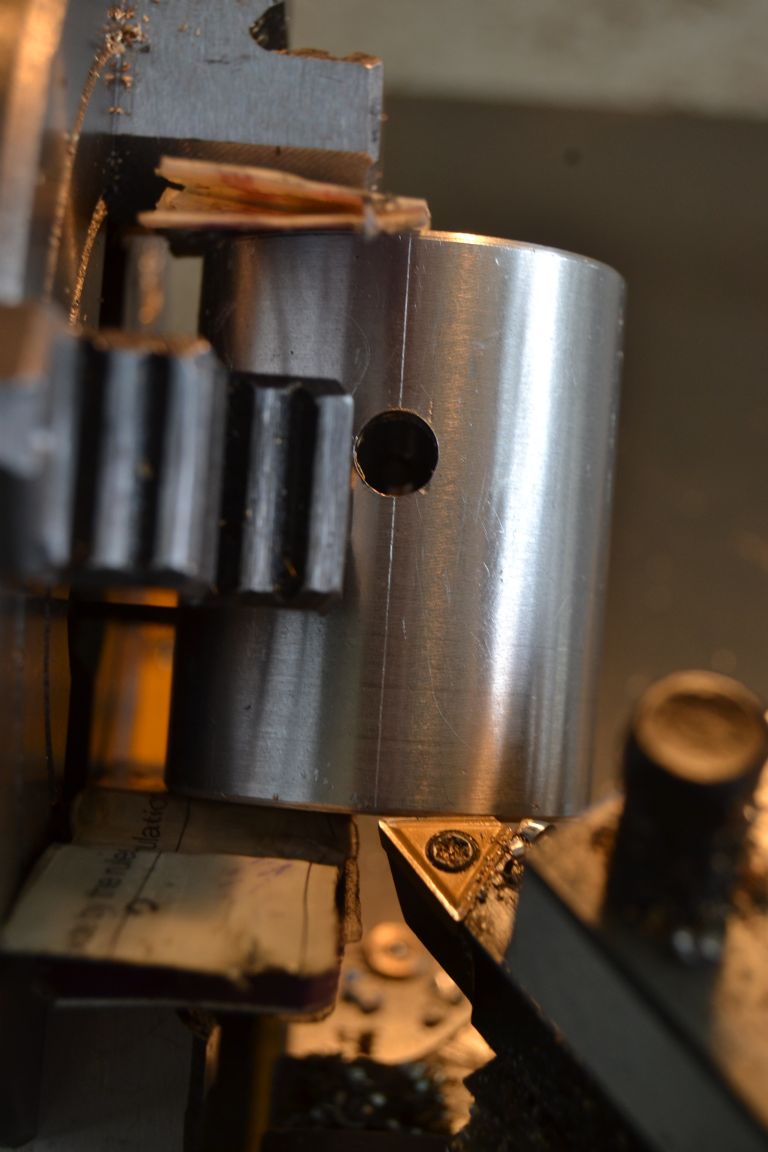

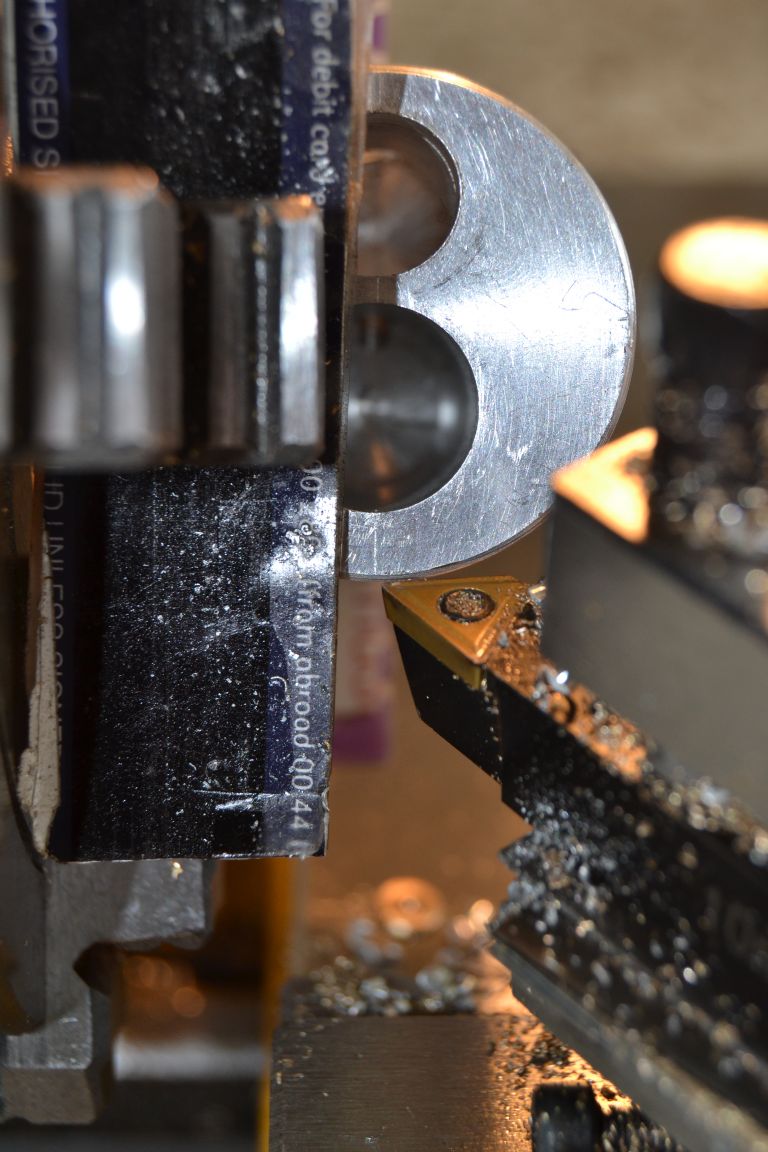

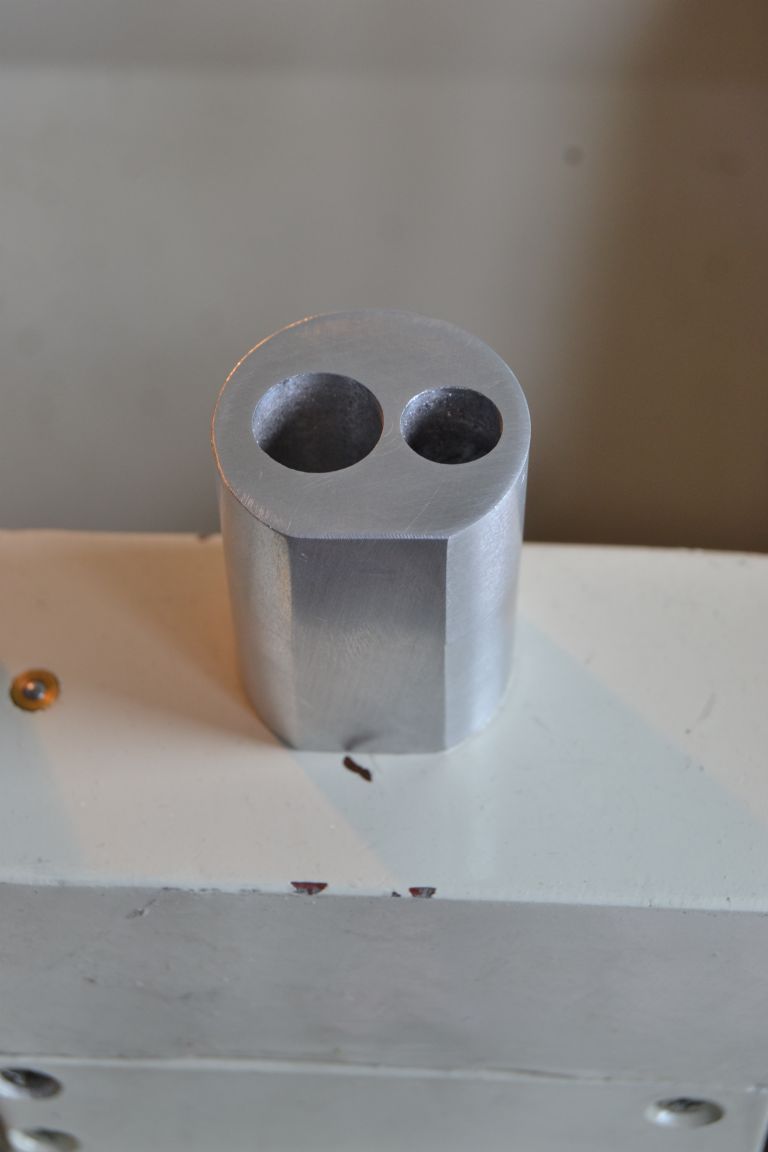

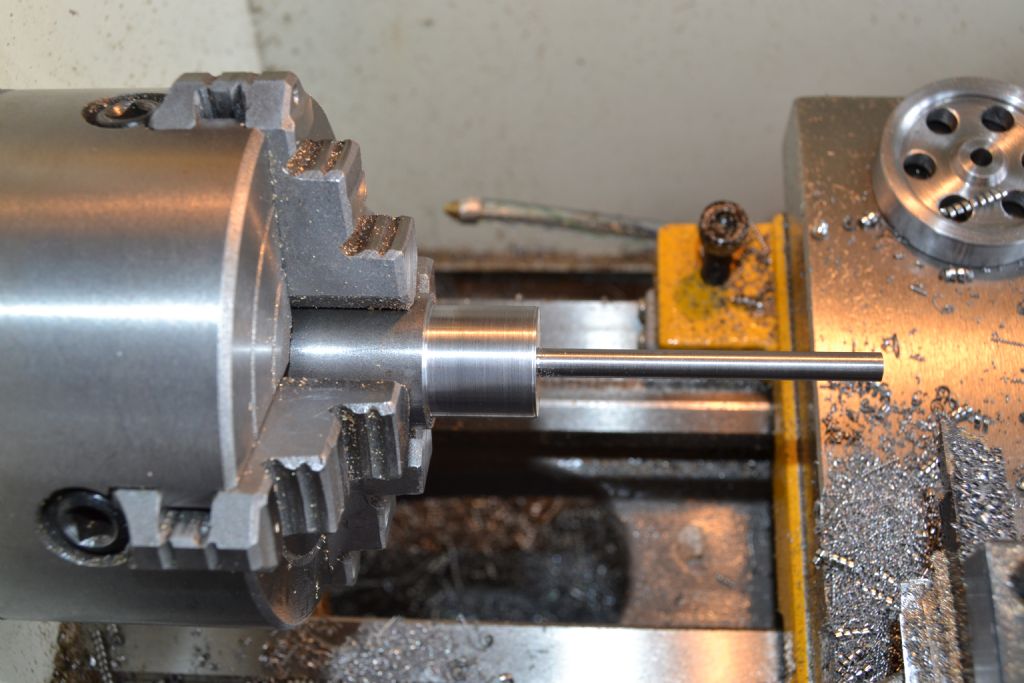

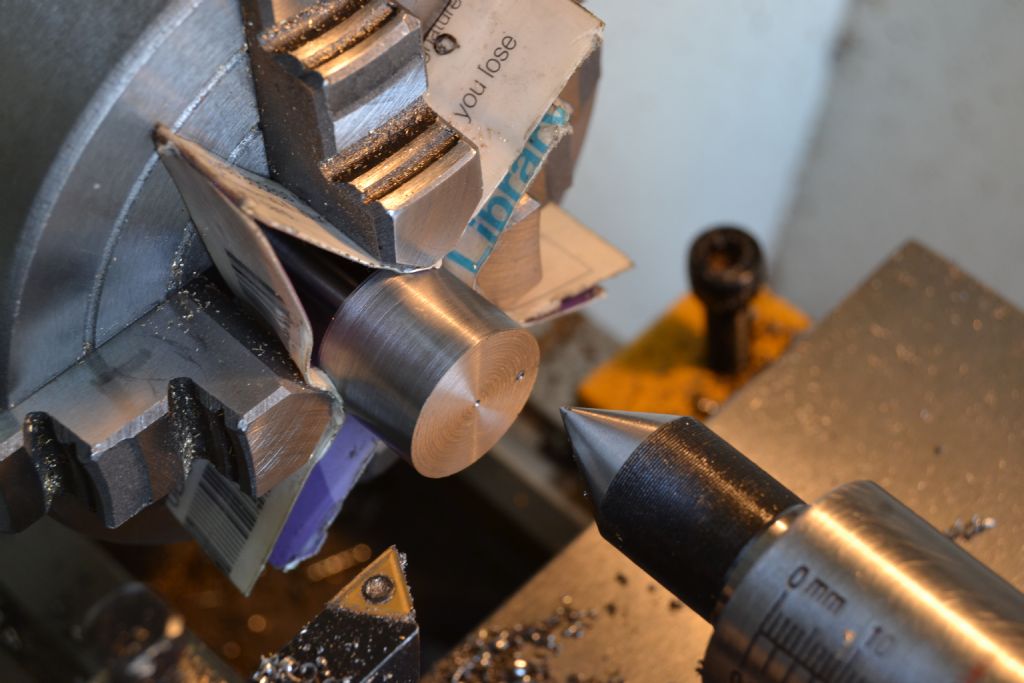

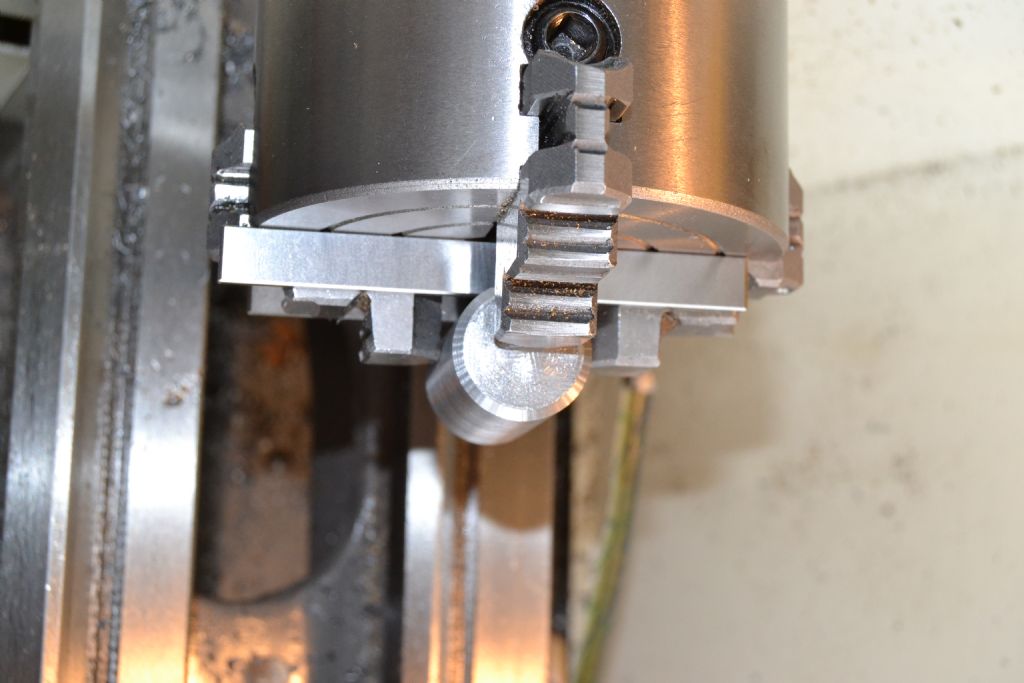

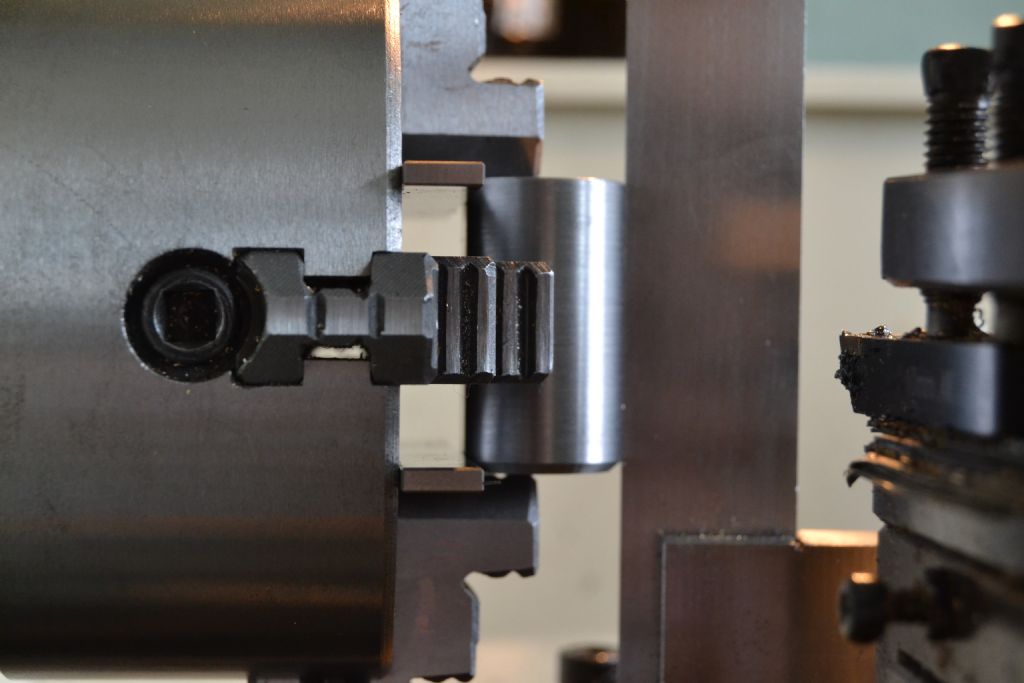

Block turned and faced to size then power piston bore done.

Steam chest bore done, I decided to make this slightly larger diameter than the plans as I think that may prove more forgiving at my skill level.

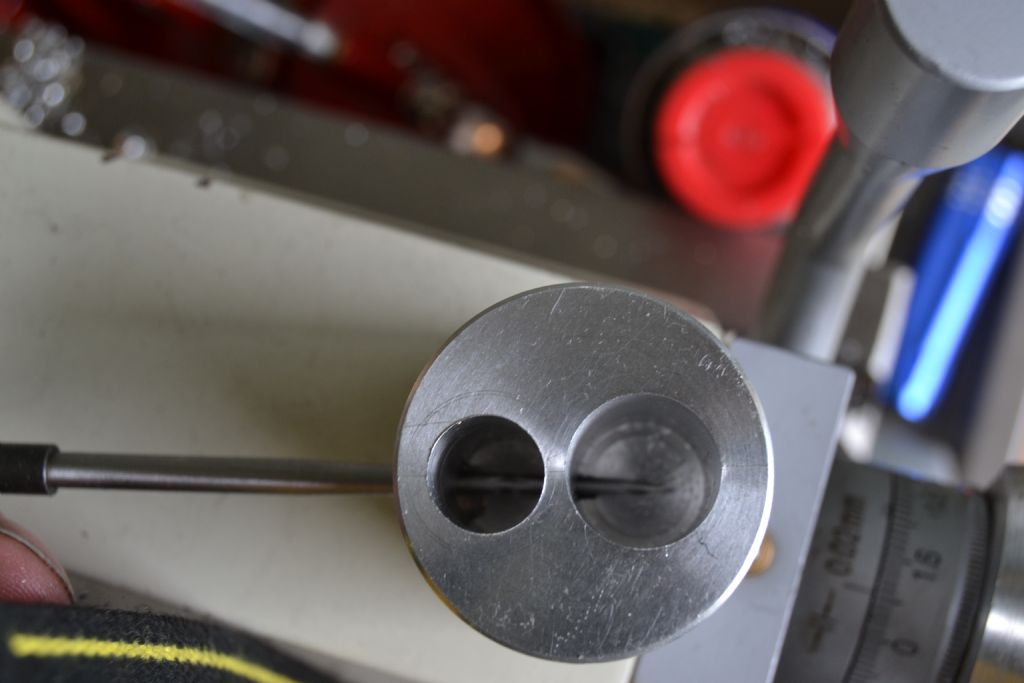

Ready to begin drilling inlet port.

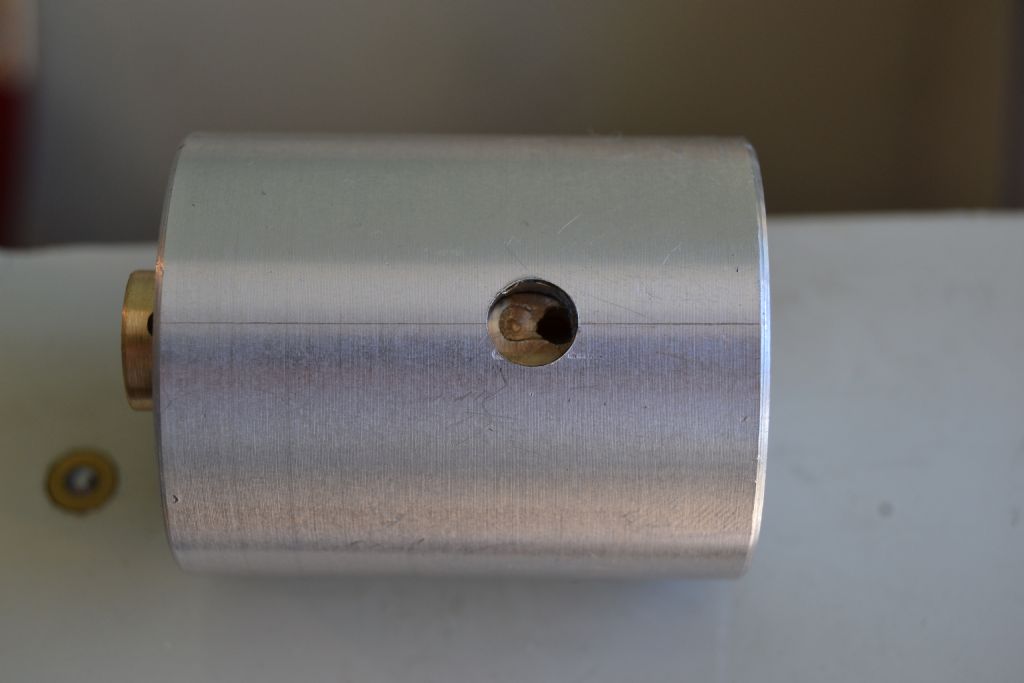

Drilled through as far as power cylinder, I was a bit relieved at this point. With my limited tools and experience I wasn't certain how parallel the bores were etc. However once the inlet was drilled through my scriber seems to suggest they are reasonably true.

I decided to omit mounting holes for the cylinder at this point as I'm not yet certain how I'll go about it but will probably deviate from the plan.

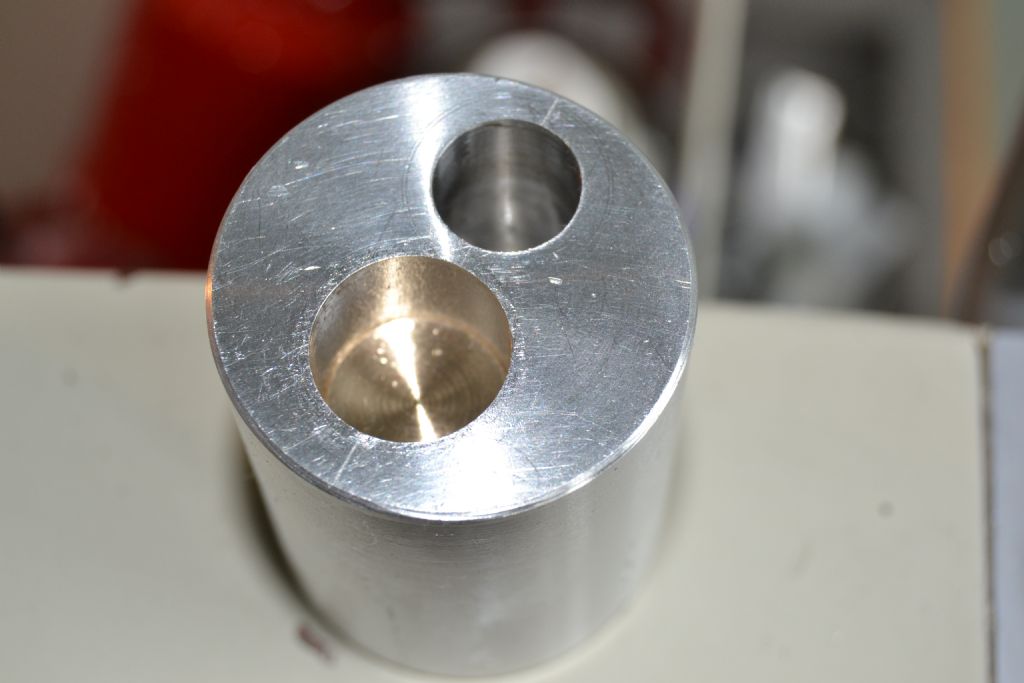

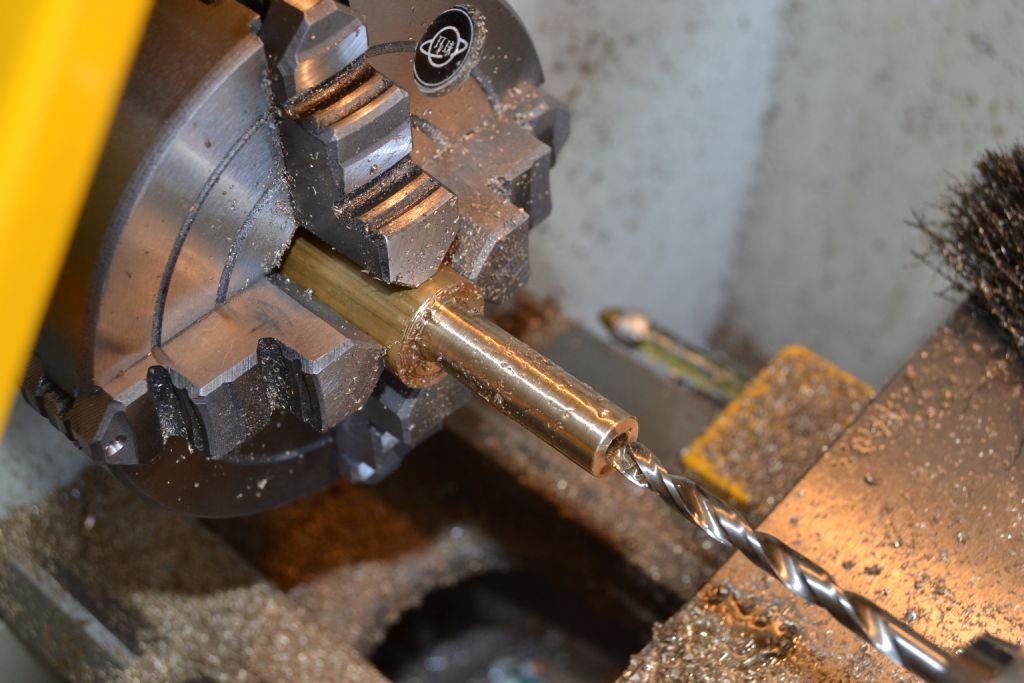

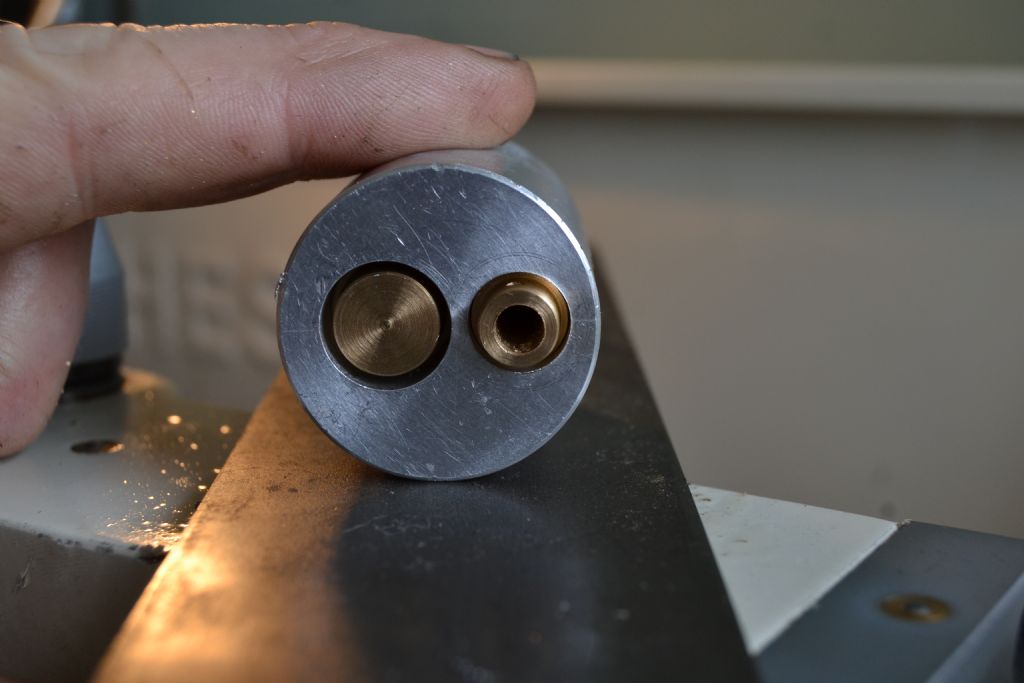

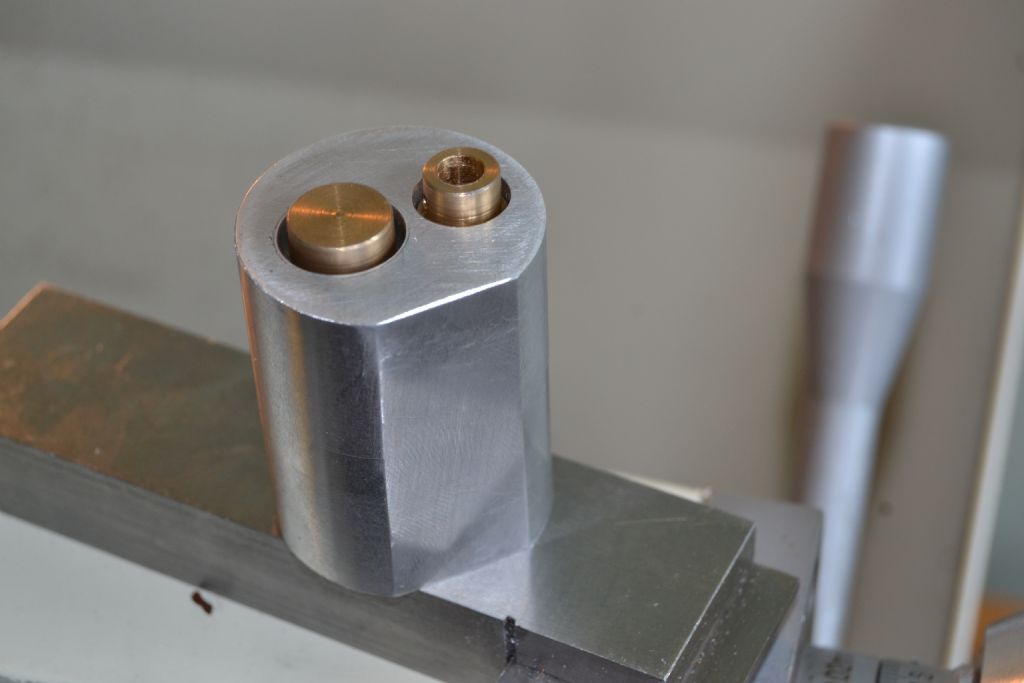

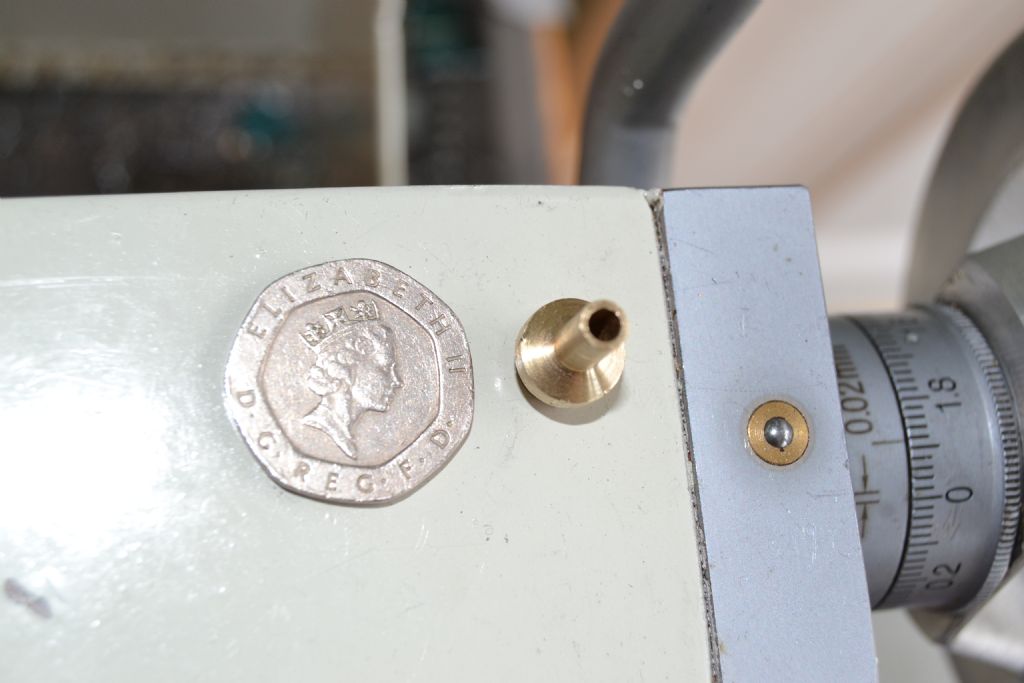

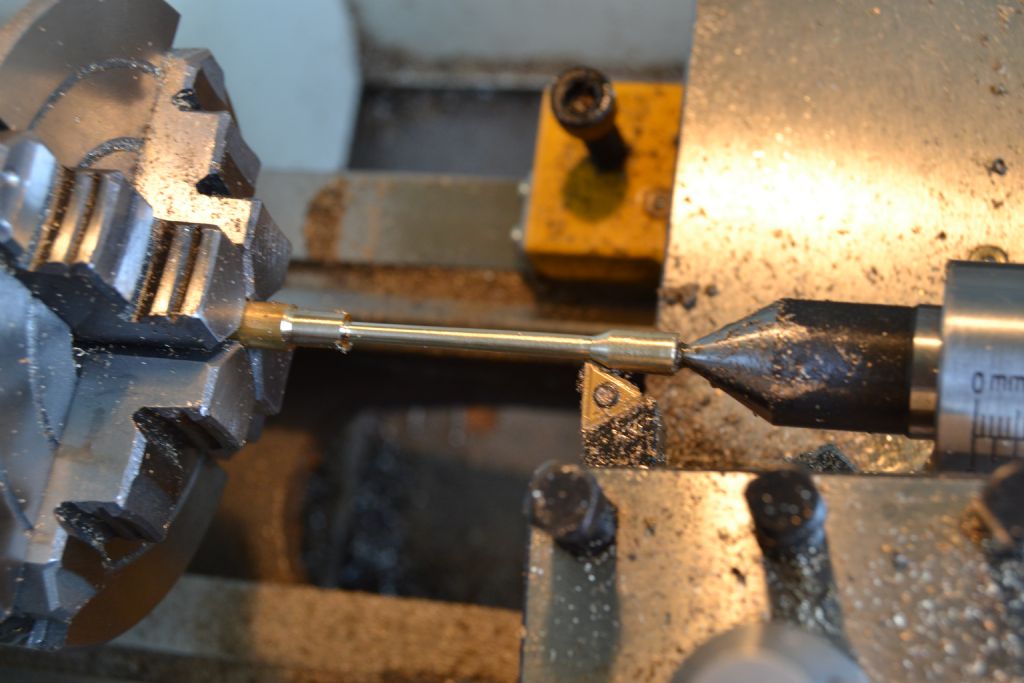

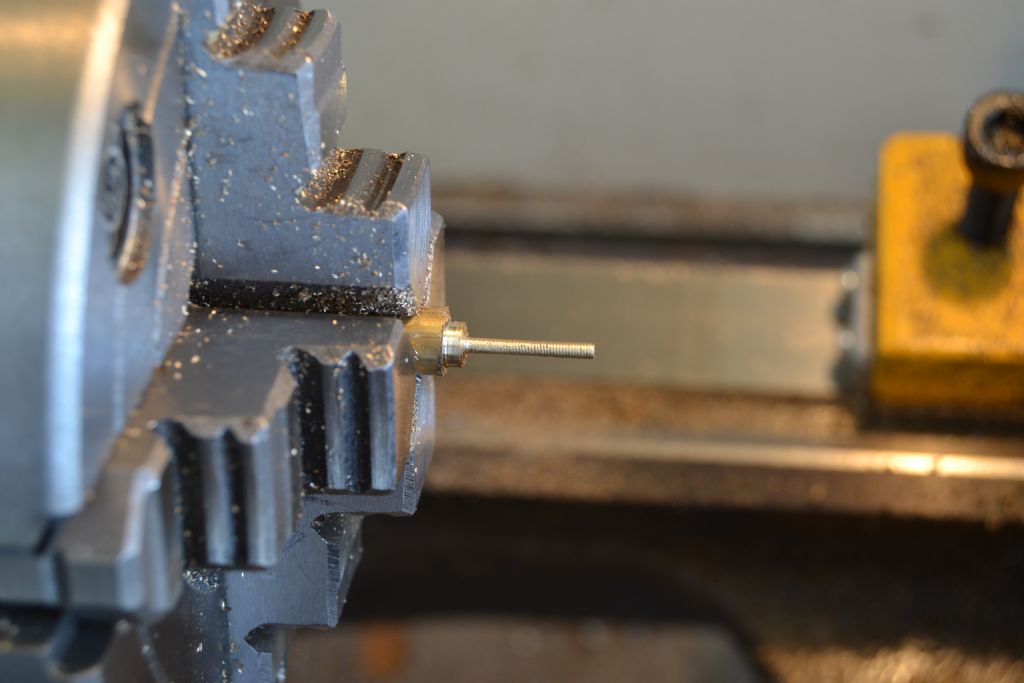

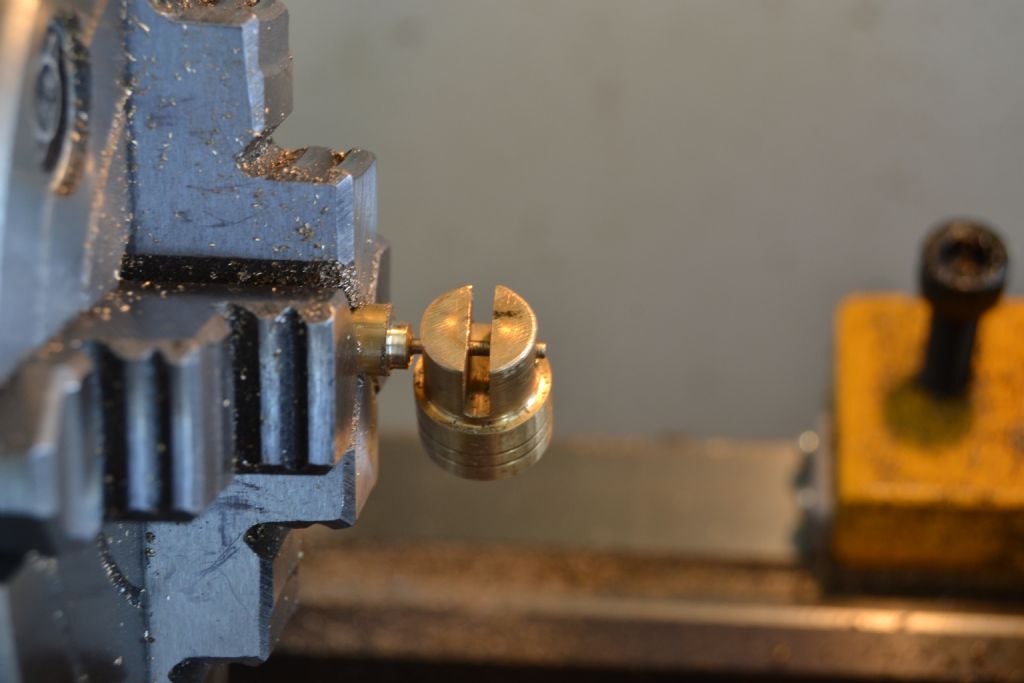

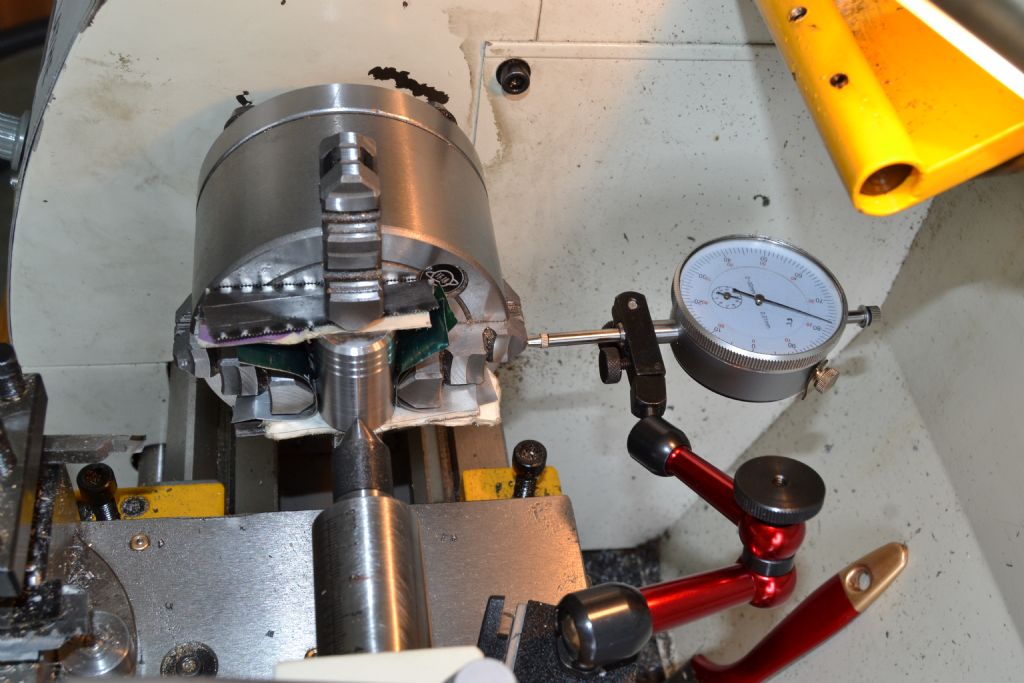

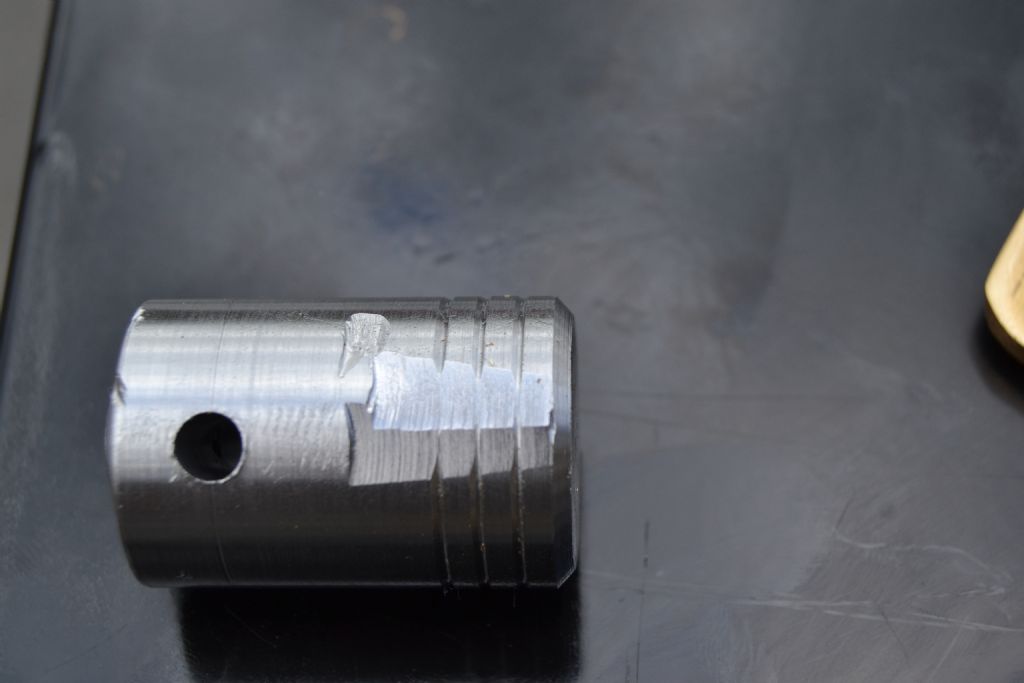

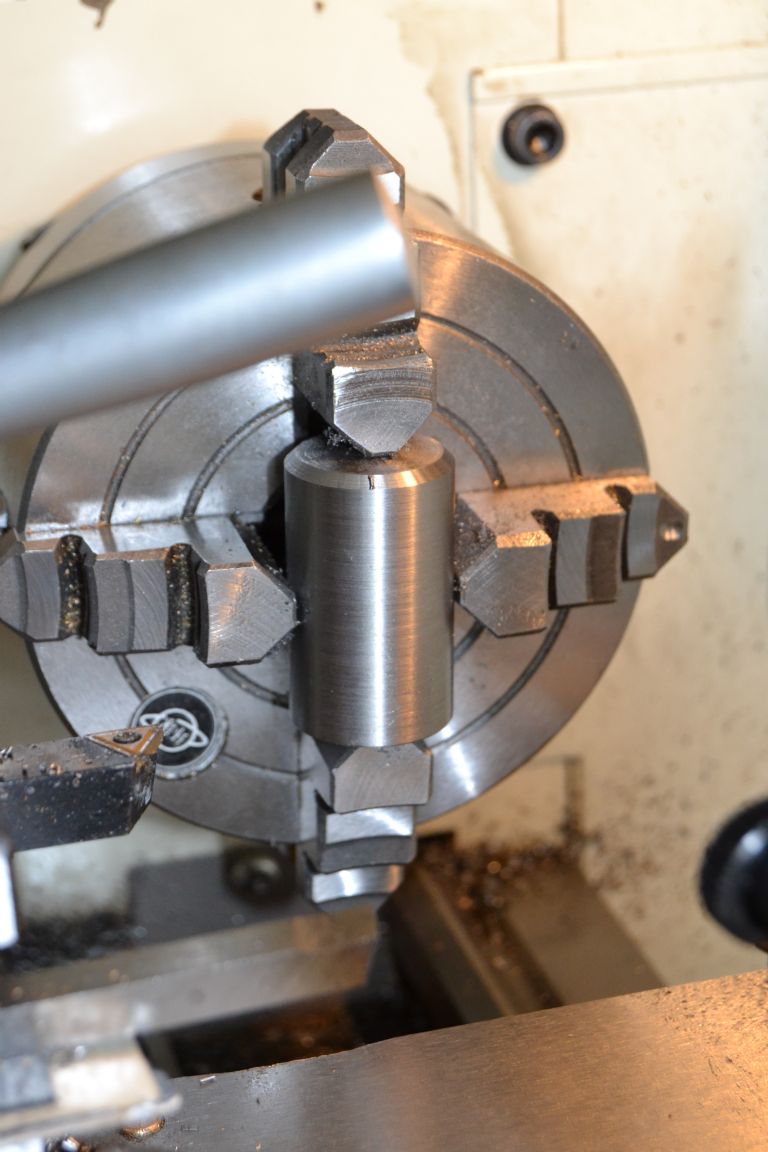

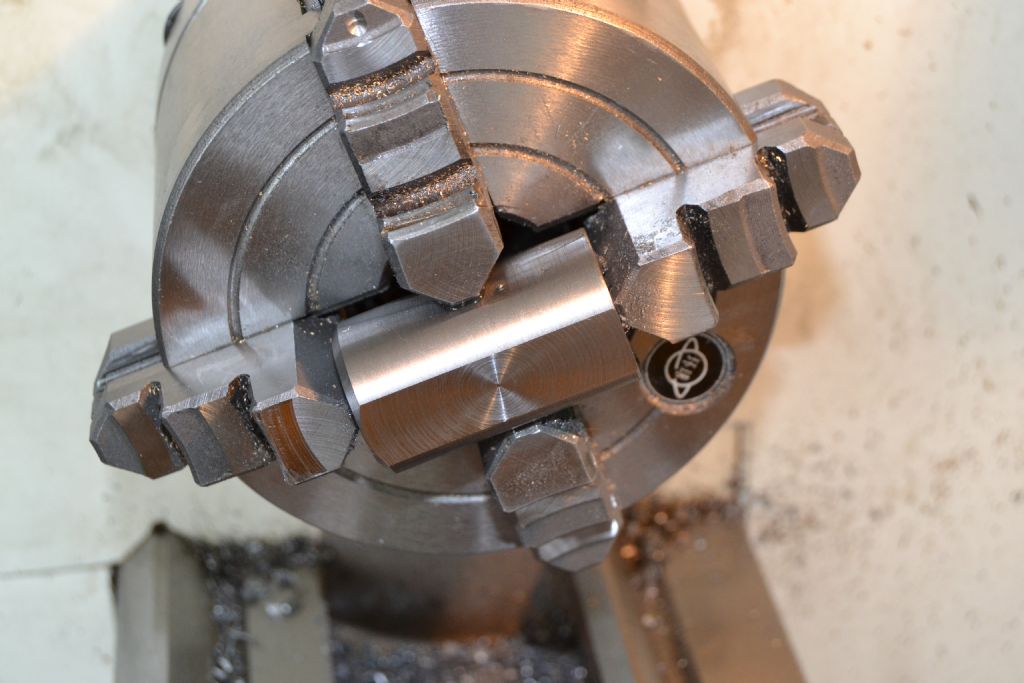

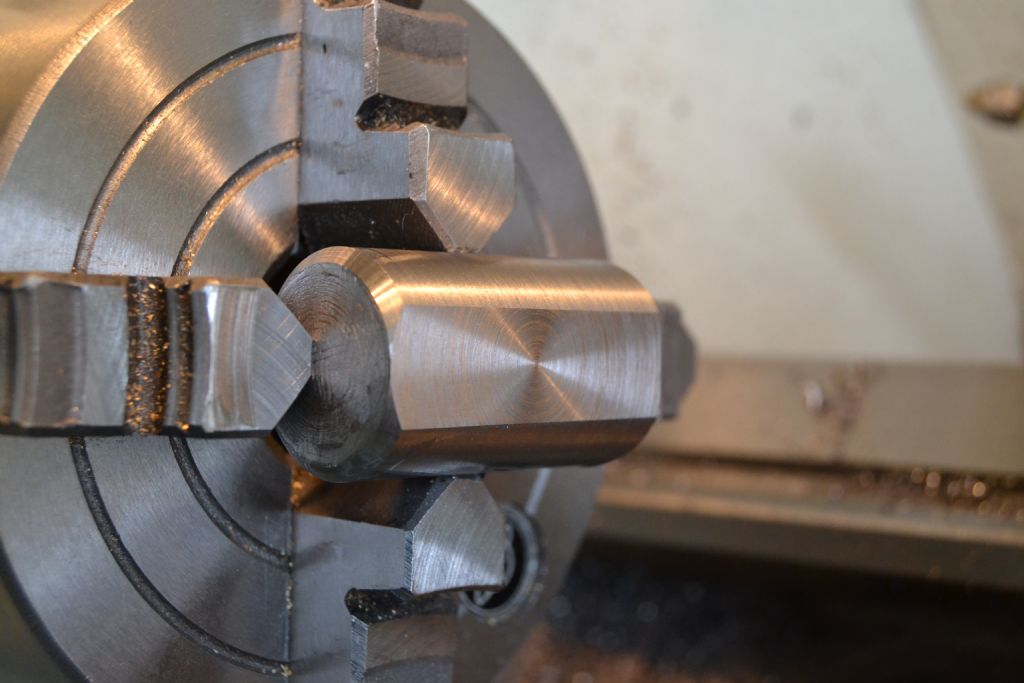

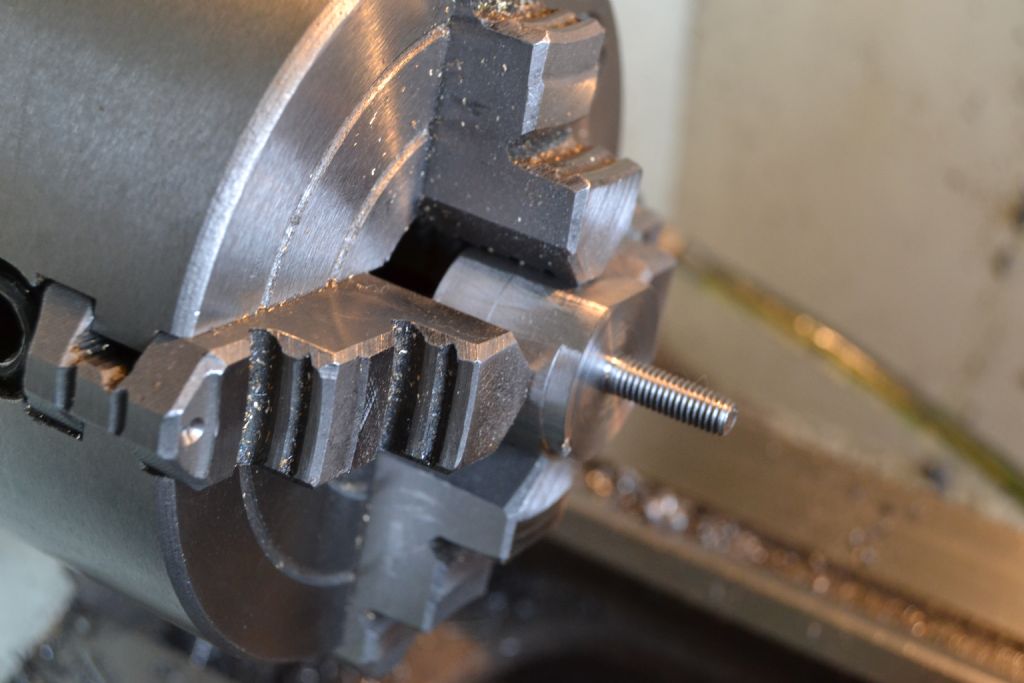

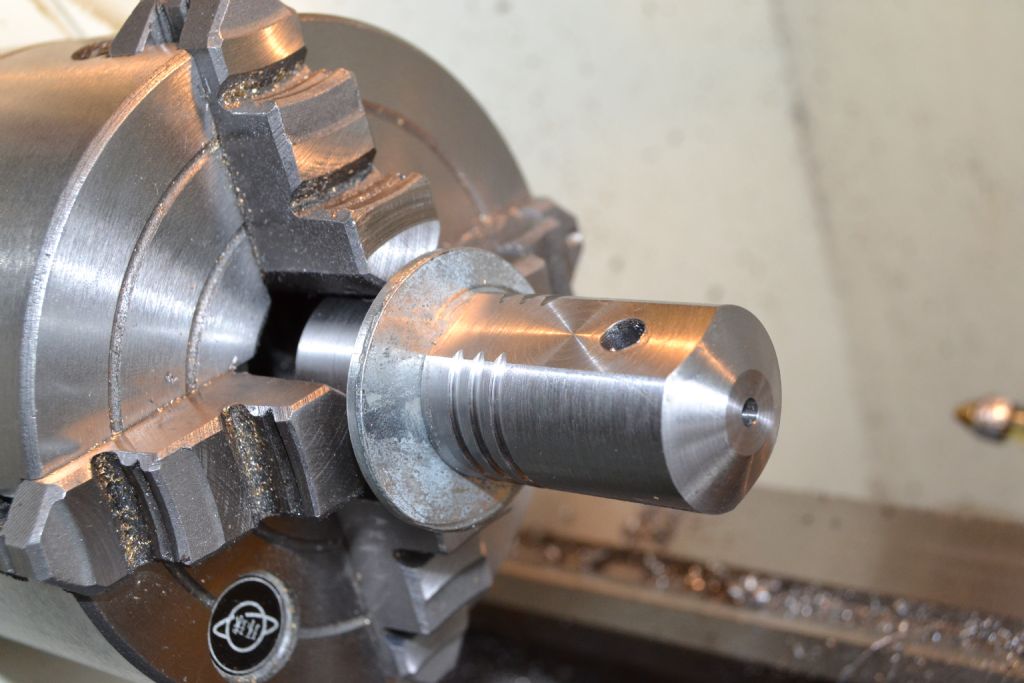

So – I decided on the piston next. This time I had a suitable piece of brass

I did damage the first piston when I turned it around in the chuck but had better luck second time

I decided to cut in a couple of very small oil rings that aren't on the plan but I thought they may help me get a better airtight seal.

Edited By Peter Nichols on 26/06/2015 12:22:38

Gas_mantle..