OK been working on doing some harrison M300 screw cutting plates.

Artwork was scanned in, cleaned up in CAD [ Cartoon Asisted Drawing ] then saved as a DXF and taken into the laser cutters software.

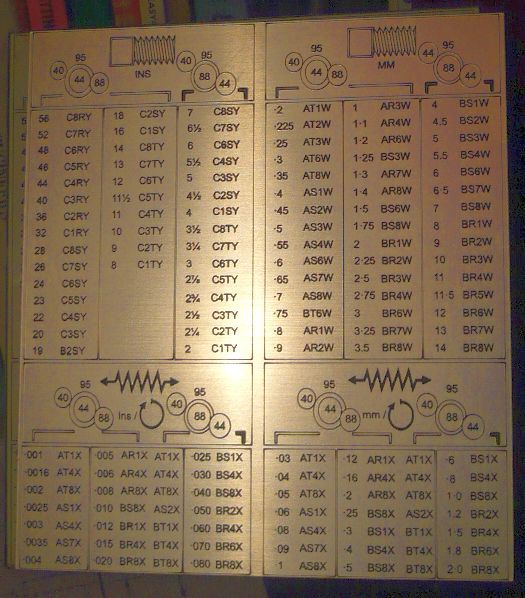

First off was a plate done out of the silver faced 1.6mm thick Rowmark type engraving plastic.

Came out really well but hard to get a good photo because of reflected light.

Plus points are it's easy to do and comes out nice. Cons are it scratches easily and will need to have a clear cover over it for workshop use.

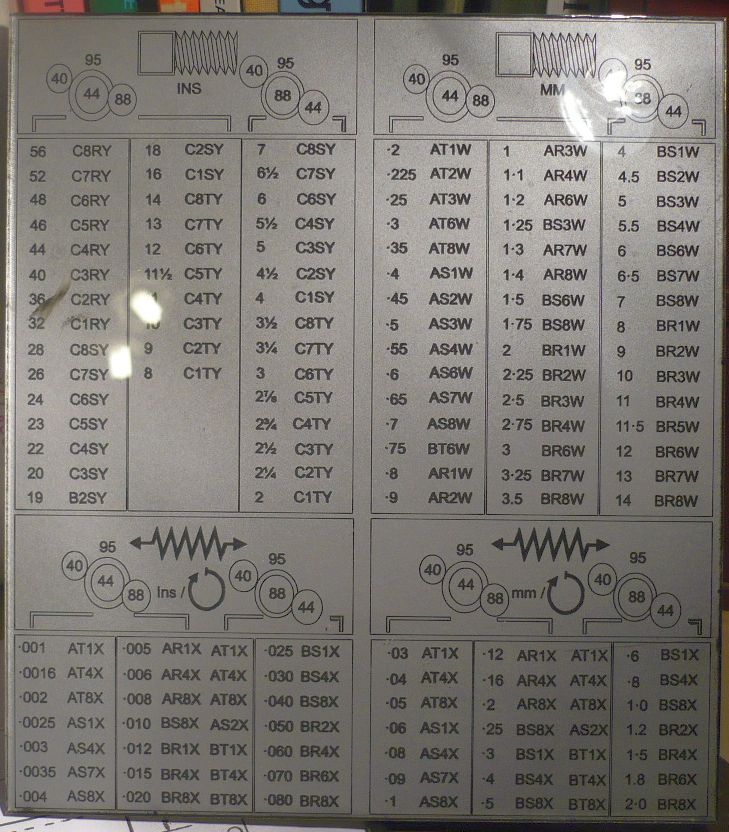

Second try was it's possible to buy reversed engraving laminate and after trials using an old front number plate I got to thinking and just sprayed the back of a sheet of 3mm perspex with cheap silver rattle can paint from the hardware shop.

Image was reversed, burn onto the silver , then rattle canned black over this

Again came out well except for the reflected light .

Pro's are it's got to be the cheapest and fastest method, durable as you can't scratch the lettering.

Cons ? can't see any.

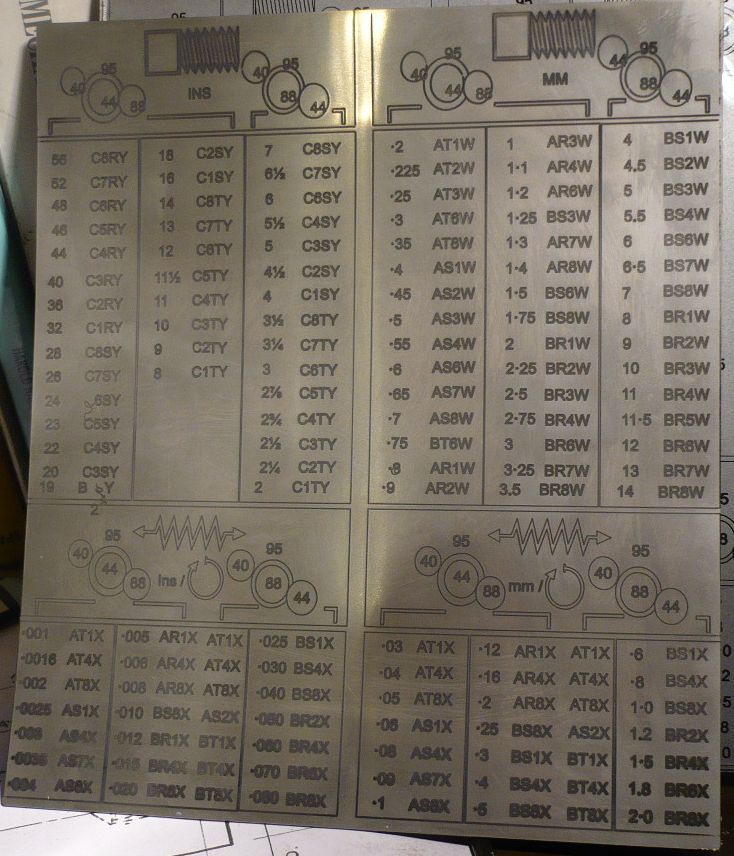

Last try was direct engrave onto stainless steel sheet. These Co2 lasers will engrave onto stainless but it's not a durable finish, scotchbrite will fetch it off easily.

Commercially there is some stuff called Ceemark which you spray on and it burns to onto the surface, it's a type of ceramic slurry made from ground up 3rd Ming Dynasty vases judging by it's price of £100 an aerosol [ no typo ]

After a bit of research on the web I came up with a link to some dry moly spray that works, bought a tin, £12 a pop and sprayed a stainless sheet up and then engraved on that.

Had problems with this one but overall pleased with the result.

Firstly because of the amount of heat going into this the plate bowed. The gobbled letters at the end of the main block are because i moved the plate trying to get a bit of tape on it to stop the bowing, which wasn't a good idea.

Lettering is thicker at the bottom of the lower block of lettering because the plate had risen up and reduced the focal length. Same at the top where the gear train numbers that were done first have missed the gears.

Best bit to form an opinion is the lettering in the middle and the feed legends towards the end.

As I say overall this is showing promise of a durable and workable system but needs to be secured to a large heat sink before cutting.

The moly has been burnt into the stainless plate and is a few thou deep, enough so that it won't scratch or wear off easily.

John S.

varonica leon.