I think we should ignore those who belong to the flat earth society and dont like their cages rattled.

I posted the question re the ML7 as I thought I had missed something and a suitable simple attachment might in fact exist.

When you have to do repetitive work, a bed stop is important and one that doesnt slip like using those plastic quiick clamps do – waste of space.

I wasnt looking for a universal gadget and those with a dovetail bed are better served with a DTI clamp

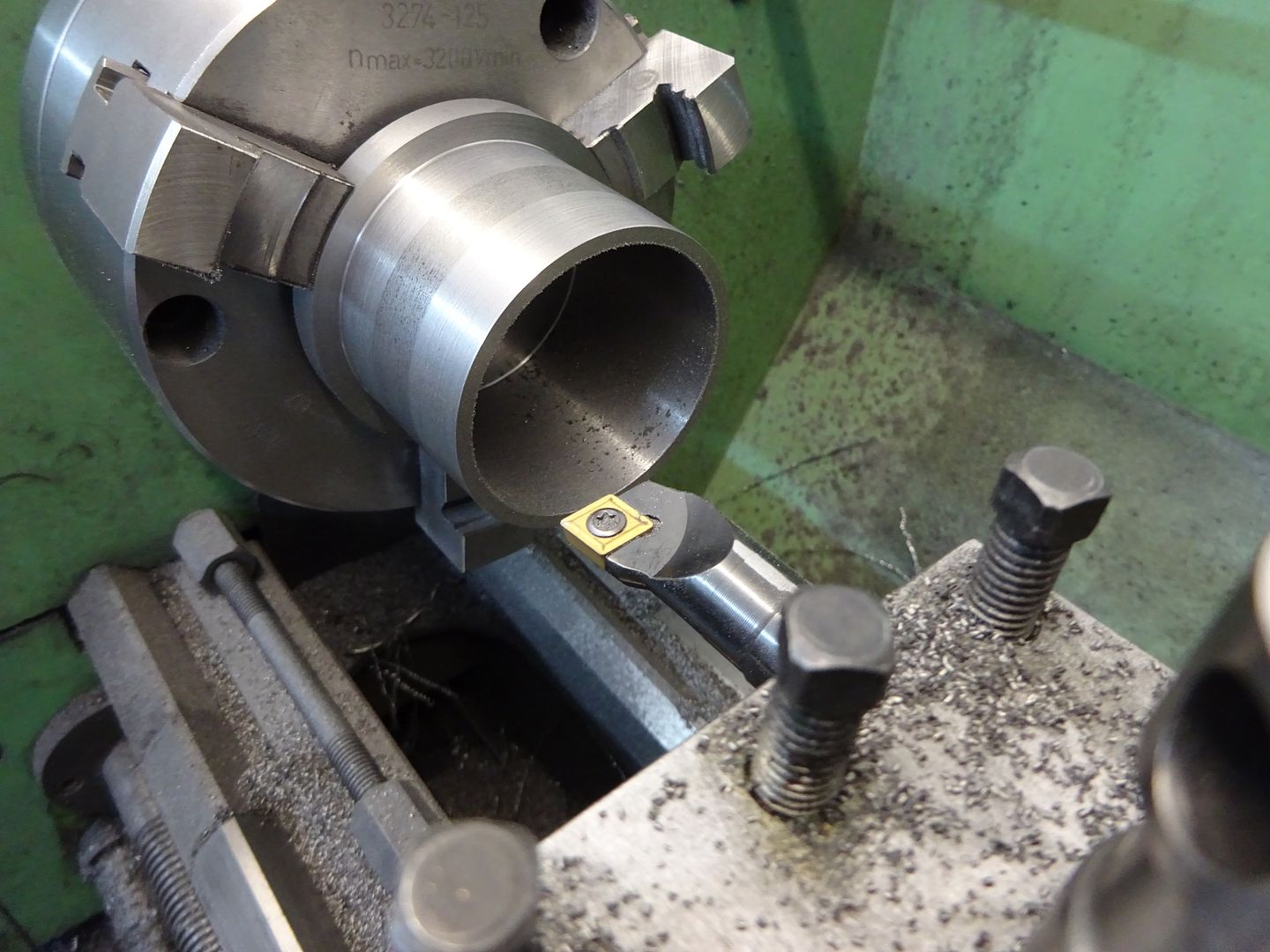

Some other robust clamps need serious milling which auntie Doreen is not up to the mark just now. Nice work on show btw.

So at the risk of a firestorm of ******* from a dizzy height here is my cunning plan

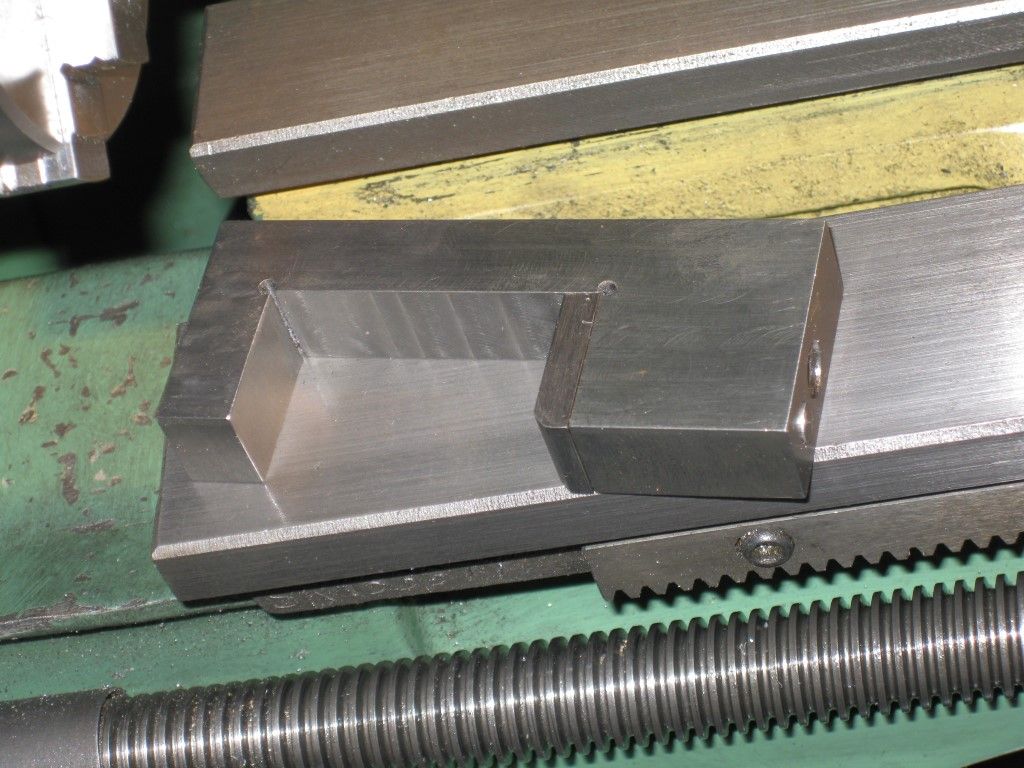

I bought one of these mini vice off ykw £9 and was prepared for disappointment as usual with PRC stuff, so to my surprise when it arrived I was surprised at the quality and precision of this die cast product – so much better than the ************** CI job crude and sloppy. It complements my little xy table also v impressive

then looking at it

It could make a bed stop clamp

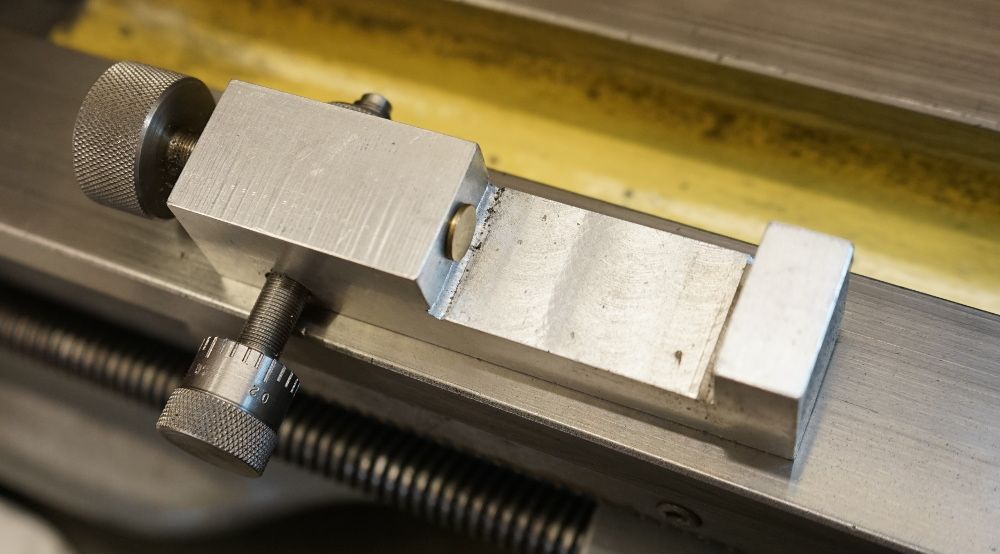

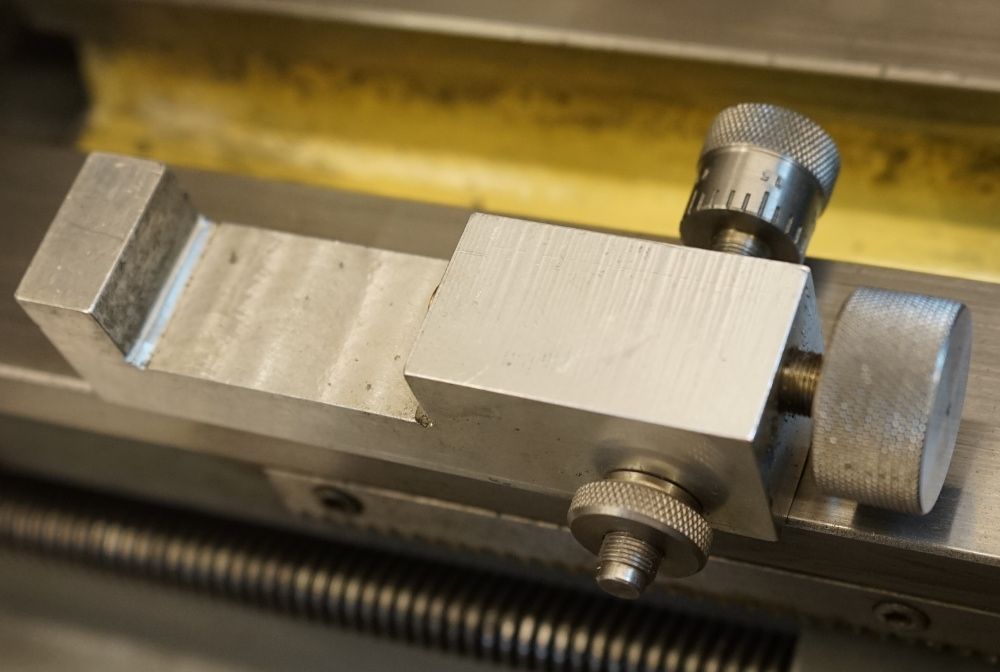

Now eagled eyed guano carriers will notice from the photo that screw stick out. In fact I removed these and what I thought were soft jaws, so it was just ally surfaces. It clamped to the bed quickly and firmly, no risk of damage

******* carriers moaned that you will have a large over hang and cant get close to the chuck

I have shown that you can clamp close to the gap bed and by removing the topslide clamp nut (leaving the other nut to do the clamping – this works) you can get fully close to the chuck and all that without having to cut off the vice flange, so it can still function as a table vice – double result

Hope this helps – living with Mrs Myford you constantly have to be inventive

Edited By JasonB on 20/07/2021 16:38:22

Pete..

Pete..