Thank you for all of the replies, observations and suggestions. I need to read them in detail and study some of the links, but I do have a few questions or comments based on them.

Pendulum and Weight in Line

I can see how this could cause problems with the pendulum setting the weight off swinging as well. I had originally planned to use a spring drive, which would not have had the same concern. I shall look at changing the layout to off-set the weight.

Plate or Frame Design

There have been some helpful comments about mounting the frame and the limitations of the design as shown. The frames are only representative at this stage, not the final shape, and I shall take into account the points that have been raised.

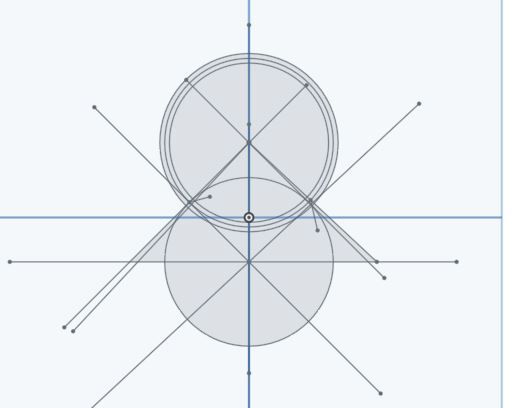

Escapement Teeth Spanned

I designed the pallets and escape wheel using the method shown below, which I found in a various forms in different places. The two short lines near the horizontal line and either side of it are the start of the pallets. Why is it better to span more teeth than this?

Remontoires and Maintaining Power Devices

I can see the benefits of these and shall mull them over. I have a commercial long-case clock that has nothing of this sort and it keeps reasonable time, but can see how these devices could improve it.

Tooth Count

Someone commented that using an 11 tooth pinion is not a nice number: there is no 11 tooth pinion in the train. The same post mentions that a 10 tooth pinion is a bad choice. Why?

The Book in the Archive

Thank you for this link. I have started to read it and bits look useful.

Regards,

James.

Edited By James Alford on 21/04/2016 07:19:10

Michael Gilligan.

Michael Gilligan.

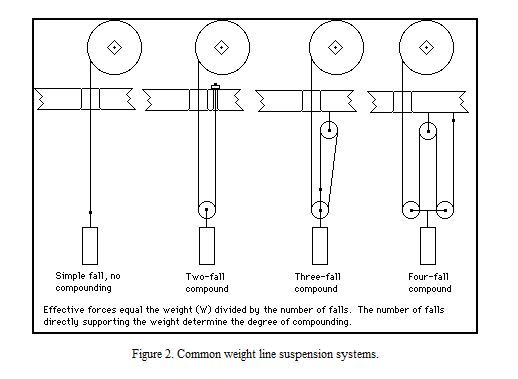

I think the intention of the most knowledgeable people here is to point out that remontoires are an advanced device and not usually part of a basic design, but a similar concept may have a place for winding the weight as a space saving device.

I think the intention of the most knowledgeable people here is to point out that remontoires are an advanced device and not usually part of a basic design, but a similar concept may have a place for winding the weight as a space saving device. That end tends to be cost more than I am prepared to pay but I am embarrassed by how many cheaper clocks I have bought over the years, and movements.

That end tends to be cost more than I am prepared to pay but I am embarrassed by how many cheaper clocks I have bought over the years, and movements.