Thank you for all of the comments and suggestions to date. As yet, I am still undecided about a remontoire, but shall study them in more depth before deciding. Although it seems the simplest, I am not keen on an electric device, simply because I do not wish for the clock to be reliant upon batteries or to need plugging into the mains.

I have revised the design, using 0.8 mod as a compromise size between 1 and 0.6 mods. With 0.8 mod, the pinions are large enough for me to have a fair chance of constructing them as lantern pinions. Anything smaller and I doubt that I would have much luck.

I have decided to use weights in the end, not spring.

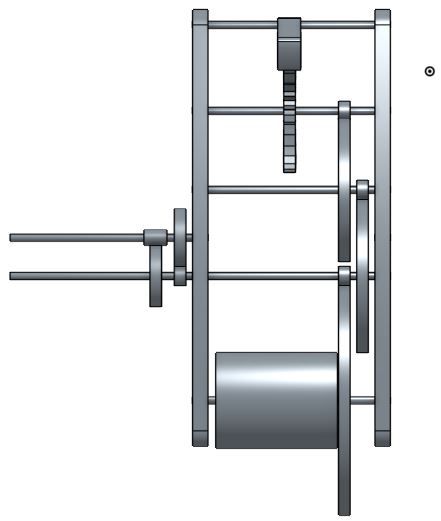

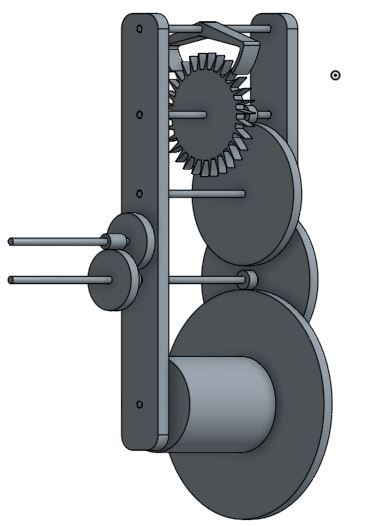

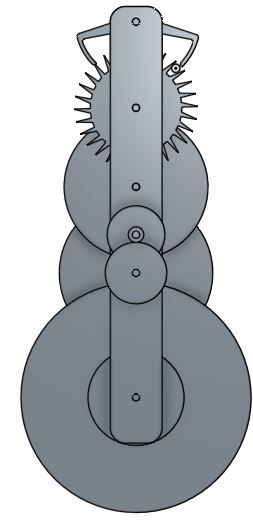

The attached drawings show the general layout, but the frames are simply representative, but finalised, as are the long arbours at the front.

I plan to use a one metre pendulum with a thirty tooth escape wheel. The tooth count and ratios that I have settled on, starting with the escape pinion are:

10: 75

10:80

10:30

8:32 (the hour wheel)

The wheel on the winding barrel is 120 tooth

Do these ratios and general layout look reasonable?

Next step – pendulum and suspension. Can anyone direct me to any links or sites which cover this area? I can work it out by studying other designs, but some advice is always a help.

Regards,

James.

Edited By James Alford on 20/04/2016 07:31:02

Edited By James Alford on 20/04/2016 07:31:54

Edited By James Alford on 20/04/2016 07:32:49

Edited By James Alford on 20/04/2016 07:57:45

Michael Gilligan.

Michael Gilligan.

All of that is some what exaggerated in places to make a point.

All of that is some what exaggerated in places to make a point.