Posted by Simon Collier on 30/10/2021 00:35:48:

Lovely animation; horrendous valve gear. I enjoyed the article. Double expansion links. What a pain!

Thanks Simon, the Gooch valve gear is interesting to design, but modern simulation techniques make life a little easier. I would not like to design this valve gear with just a drawing board! It is incredibly interesting to see all the linkages working in-between each other. I must say the Ballaarat valve gear hasn’t given me any of the issues I’ve read about, even back notching (within reason) is as good as any of my other locos. In fact it behaves the same as my Walschaerts fitted 3.5g 2-6-2 loco in terms of coal consumption, water consumption etc. (this loco has similar design tractive effort, boiler size etc.).

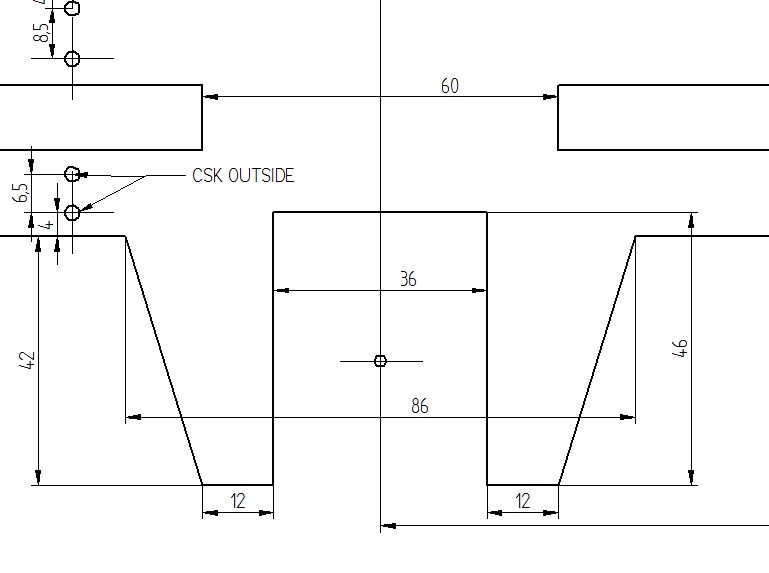

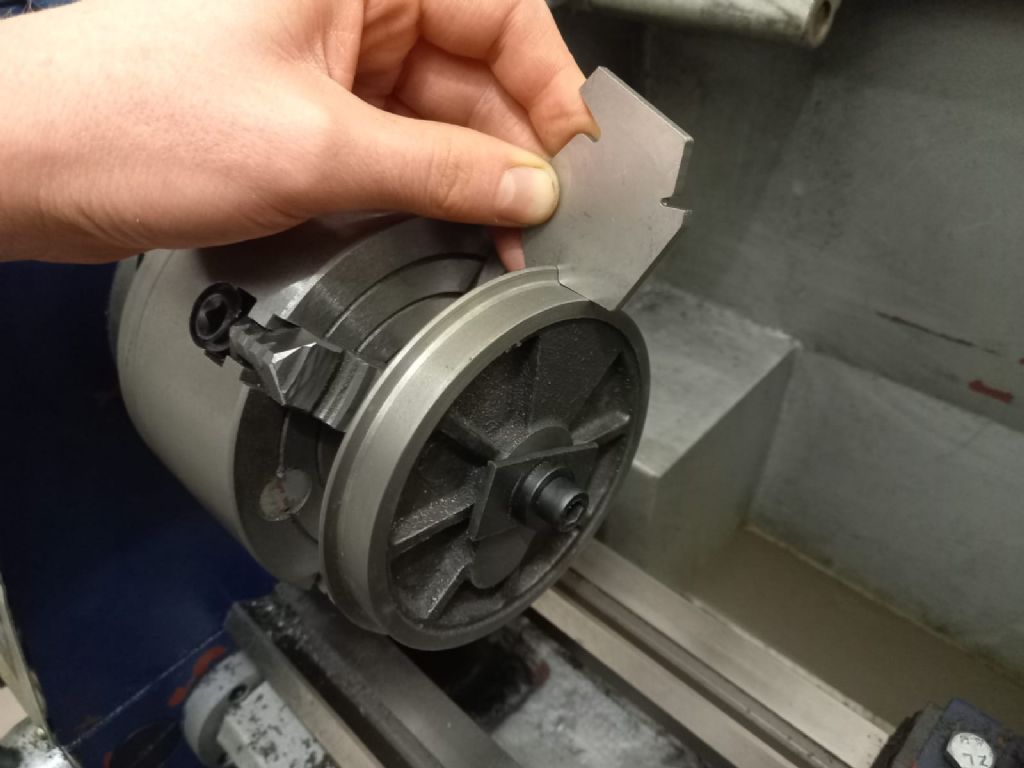

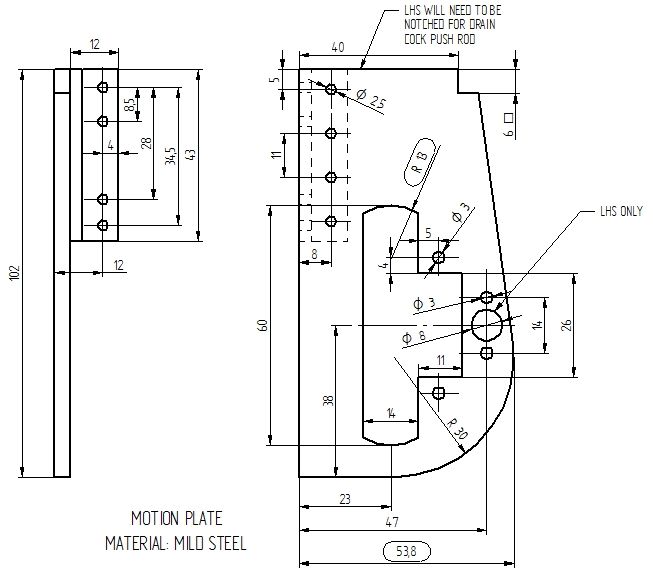

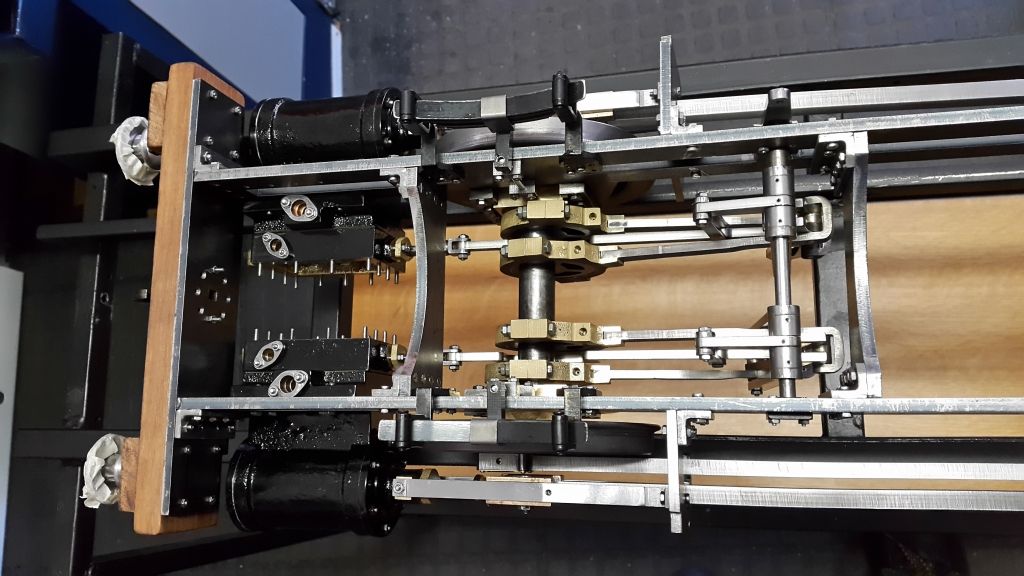

The expansion link wasn’t that difficult to make, it was easier than the normal type because the laser cut surface was of better quality (thinner section). If I were to machine these from scratch they would be held together and match machined so not much extra work. Some pics…

Luker.