I would just like to clarify what I have said…

First in an email reply I said: 'The ball nose endmills are correct and typical of the basic TiN coated endmills we supply. There is nothing wrong with them as supplied.' I followed that by saying that I have had zero complaint for this product… which is the case.

We have been selling this, as is, purchased from the same manufacturer, with the same 'shape' specification, for nearly 18 years. It is no different to what is available at the basic – budget end of the market for yellow TiN coated product. We are one of the smallest 'quantity' buyer. His main buyers are Americans, who buy a much larger volume from him than I do. The question over the shape being right or wrong has never been brought up to date. Either the buyers don't know, or they know, right or wrong for their application, and/or accept it for what it is in terms of shape.

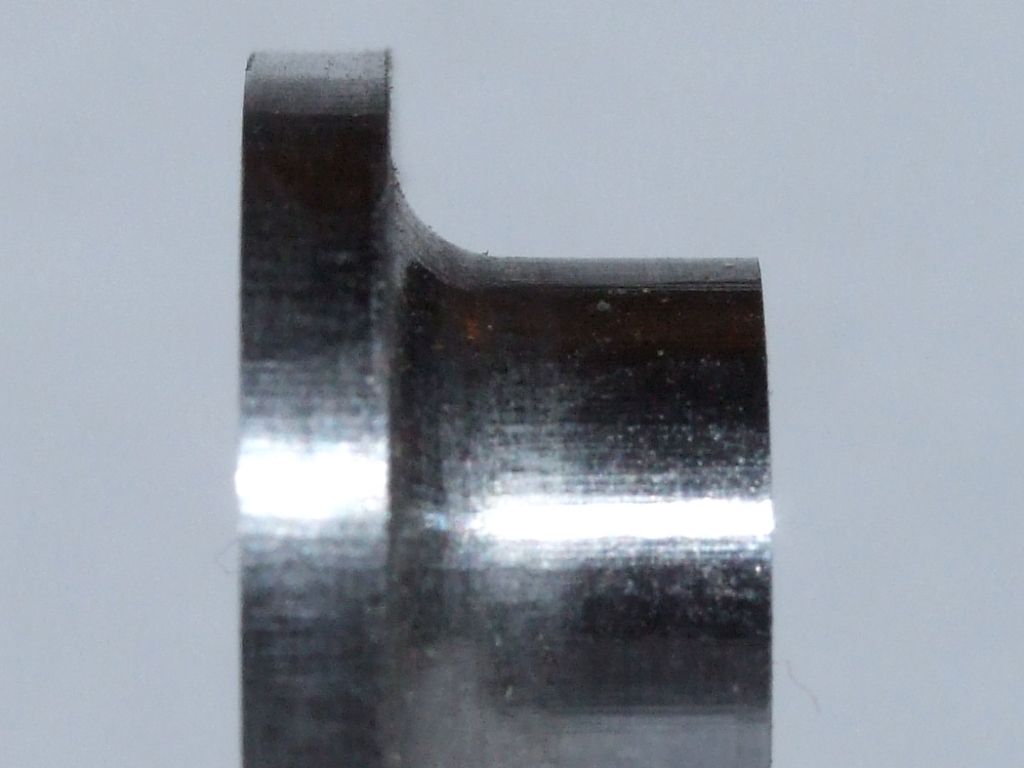

How the shape compares to the 'premium endmills – HSS or carbide' which we sell, I also don't know, but I expect them to be better and different from the budget end end mills. Unfortunately we do not sell 11mm or 7/16".

In our conversation, it is also correct that I said that the TiN coating on the budget endmills will behave differently in cutting/finish when used on non-ferrous material such as aluminium (as what in this case), vs. ferrous material, purely because this ball nose end mill is coated, and for aluminium it is better to have un-coated.

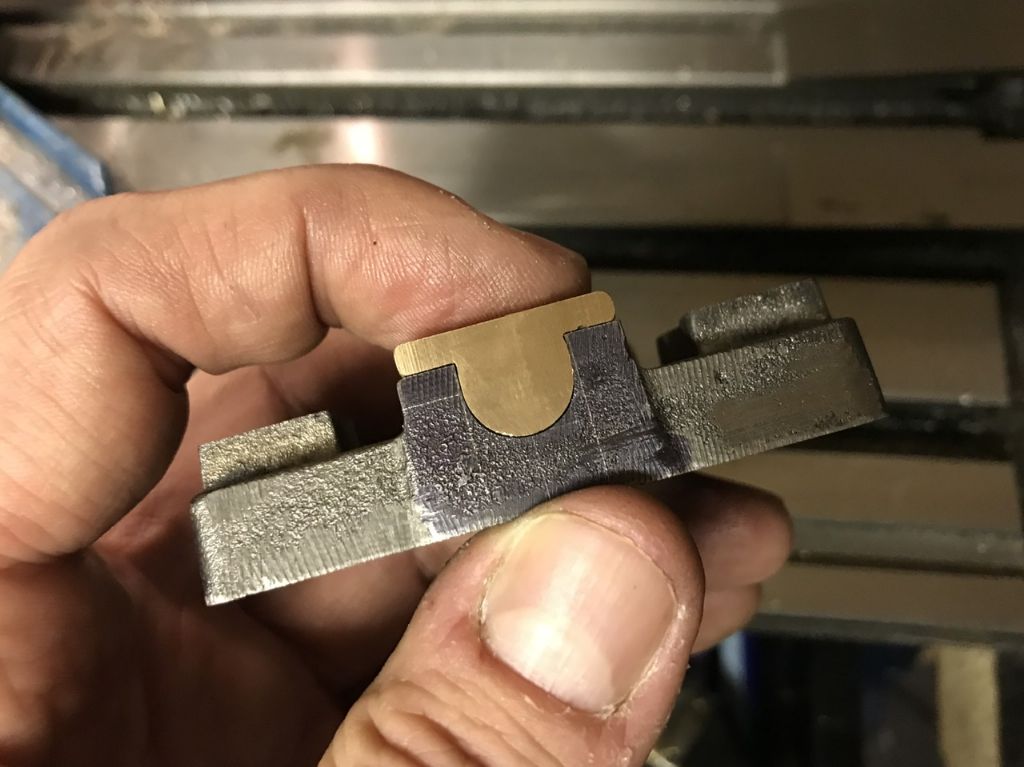

Jason PM'd me with a suggestion for him to check the differences between the budget end ball nose endmill, compared with premium end mill. He has/may have a 7/16" Hertel ball nose end mill. So, I will send him the same ball nosed end mill for him to compare, on different materials.

old mart.