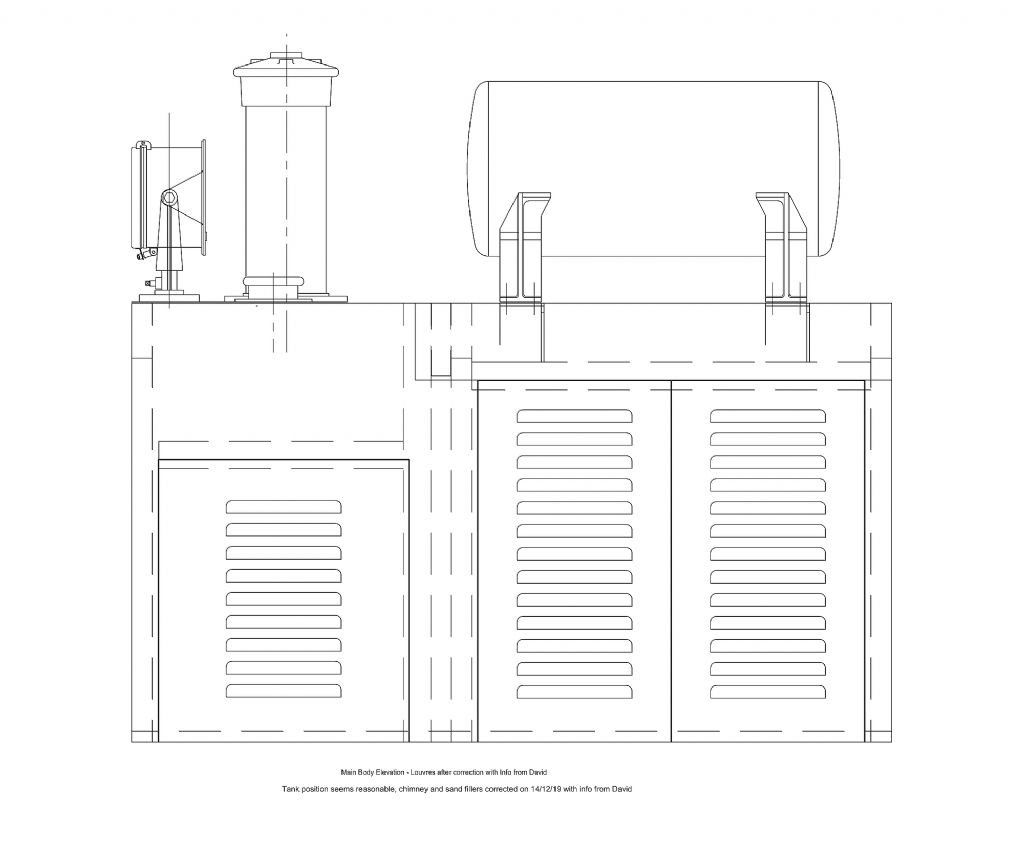

Baldwin Gas Mechanical Body drawings started

Baldwin Gas Mechanical Body drawings started

- This topic has 19 replies, 1 voice, and was last updated 19 December 2020 at 18:55 by

Steve Addy.

Viewing 20 posts - 1 through 20 (of 20 total)

Viewing 20 posts - 1 through 20 (of 20 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

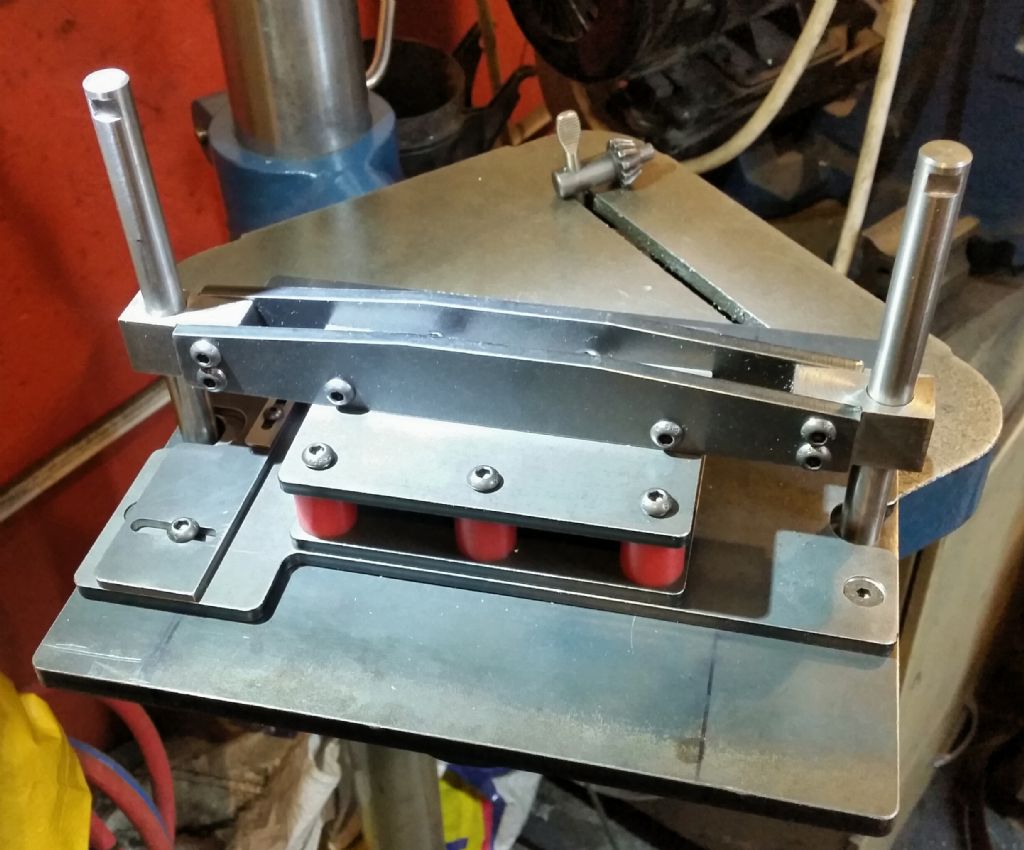

![20201217_184543[1].jpg 20201217_184543[1].jpg](/wp-content/uploads/sites/4/images/member_albums/153167/883833.jpg)

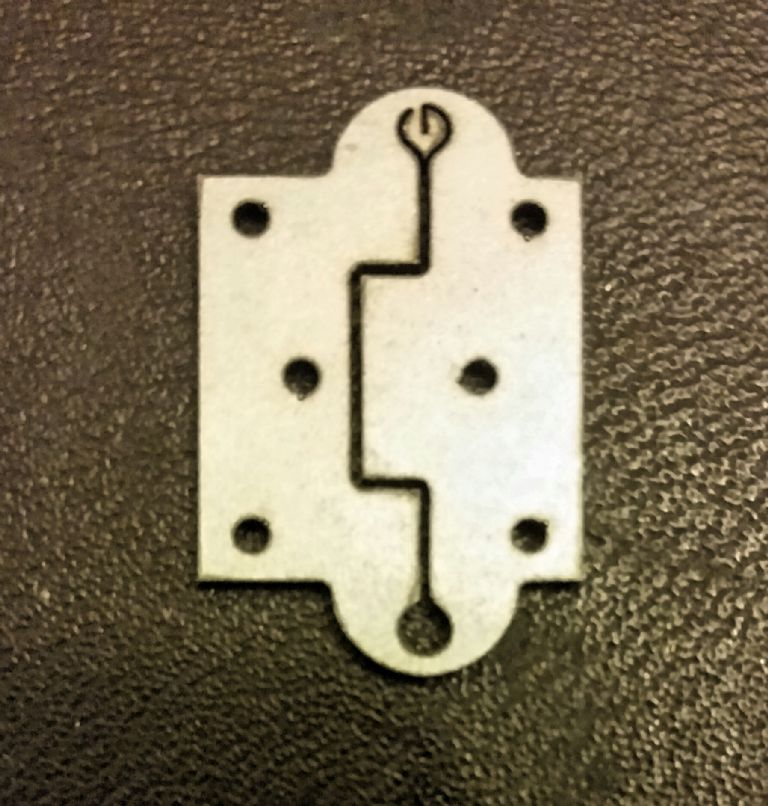

![20201219_130042[1].jpg 20201219_130042[1].jpg](/wp-content/uploads/sites/4/images/member_albums/153167/883834.jpg)