Hello all, interesting question.

First observation is that you'll never get a pretty slot using a saw with set on it. So using hacksaw blades whether they're wavy set or a normal wood saw with side set ain't going to cut it, if you'll excuse the pun.

The slotting file is the right tool, and I seem to remember correspondence from Ketan a few months ago saying he'd bought some – inadvertently – and were they of interest. Might be worth a call. A slotting file is a thin file with no teeth on the faces, but teeth on the edges so it cuts sideways – or downwards if you hold it on edge.

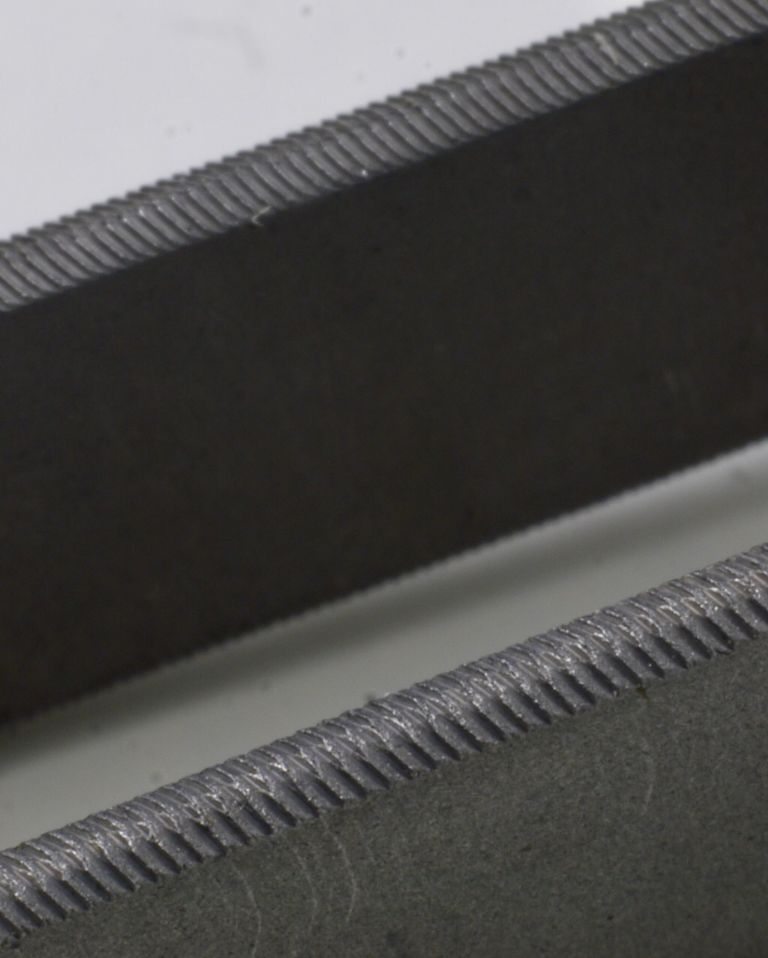

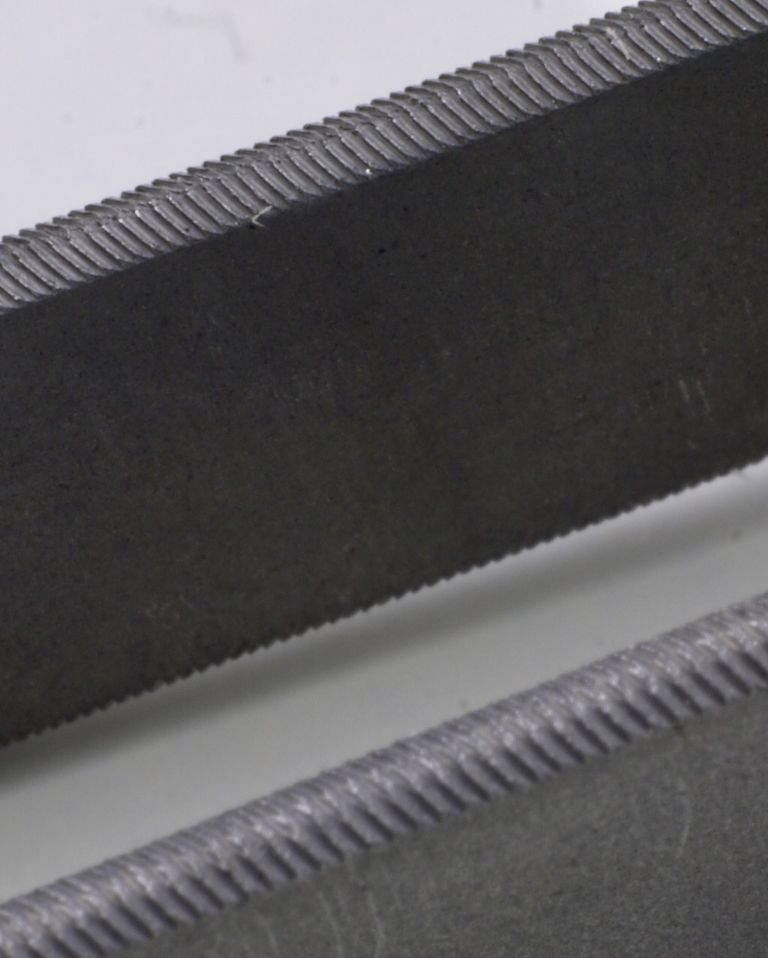

A razor saw has also been mentioned – that's what the top saw in this pic' is:

xxx

That's an Exacto razor saw, and it will cut brass but the blades aren't very hard and you'll lose the teeth pretty quickly. It's really intended for cutting wood, particularly balsa or similar.

The bottom one is a jeweller's backsaw – if you can find a source of good quality blades it'll cut anything a hacksaw would, as it's designed for cutting 9 ct gold which is pretty hard. The blades are removable from the brass back, and usually double sided, but beware of cheap and nasty blades they won't last as well as the razor saw. My Dad was a silversmith, we used to have periodic expeditions shopping for this sort of stuff round the Hockley Hill area of Birmingham, but I've lost touch with this over the last thirty years and I don't know where to buy these blades. I remember the good blades were expensive, but the cheap ones were absolutely useless!

The backsaw willl give you a good groove to guide the slotting file and remove the majority of the metal, but the blade on this one is only 0.35 mm thick so you need parallel cuts or follow with a narrow file to get a slot which looks in proportion. You used to be able to buy blades of different thicknesses.

HTH Simon

Edit – MichaelG has – as oft before – pipped me to the post about ARC's slotting files.

Edited By Simon Williams 3 on 27/11/2019 14:36:30

Allen Norris.