The principle is common to most lathes.

'

Back-gear is a low-speed range for screw-cutting and turning large diameters and often, awkwardly-shaped or interrupted-cut work-pieces.

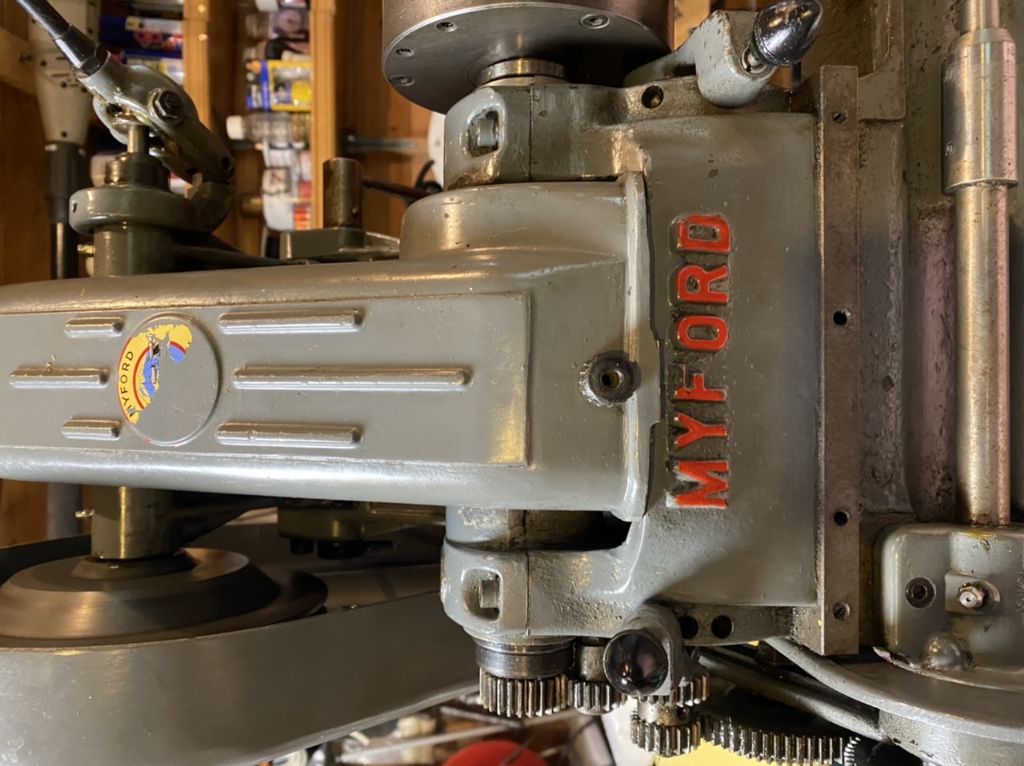

VItal: To use the back-gear the main drive from pulley to spindle must be disengaged; and on the ML7 (certainly my edition) this is by slacking (not removing!) a small socket-head screw on the face of the spindle pinion at the chuck end, moving it outwards and re-tightening it. It disengages a simple dog-clutch within the gear.

Access is restricted and needs an Allen-key with its short end, cut further short.

NB: Never use back-gear as a brake for removing a tighly-fitting chuck by impact. That is a recipe for broken gear-teeth or other damage.

'

As Dave says, the tumbler-gear controls the direction of rotation of the lead-screw, for cutting left- as well as right-hand threads.

Neutral – central pin-hole, so when you are not using the change-wheels and leadscrew, they are not dragged round unnecessarily. It reduces power-consumption and wear.

You also put it in neutral if you operate the lead-screw from a hand-wheel (an optional extra).

I would not like to say which of the two engaged position gives the normal, fine-feeds and right-hand thread position (cutting towards the chuck) because I have fitted a gearbox to my lathe; but it is simple to establish.

My approach without gear-box: Set up the required change-wheels; ensure the tool, saddle etc. are safely clear of the work and chuck; set the lowest speed pulley and back-gear; engage the tumbler. Then engage the clasp-nut and watch which way the saddle moves during a few chuck revolutions.

This is my habit especially on the Harrison lathe, as that has additional gears that also affect the direction!

I would not worry too much about screw-cutting at this stage. It is not especially difficult, but it does need general turning experience and familiarity with the particular lathe, first.

Howard Lewis.