Being of oriental origin (Taiwan or China ) the gears are most likely to be Module., and as Jason says Mod 1, Mod 1.25 or Mod 1.5

On my larger Taiwanese lathe, (Think Warco BH600 or Chester Craftsman ) the changewheels are 1.25 Mod , and the pinion that engages with the rack on the bed is 1.5 Mod )

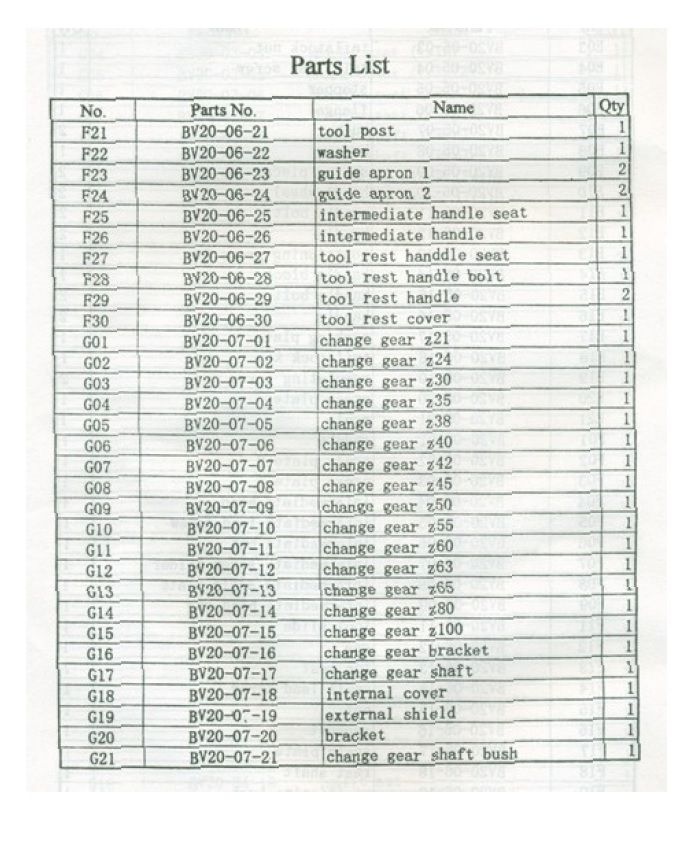

The chances are that the same lathe will have been imported by others, such as Warco, Chester, or Arc Euro etc, spare gears shoulkd be available.

Often changewheels increment in 5s, starting at 25 or 30 teeth, and going up to 80T.

The Sieg SC4 includes a 127T gear so that despite having a Metric Leadscew, it can cut Imperial threads.

Even id you don't want to cut Imperial threads, a set of changewheels will allow you to set up for a dine feed.

Most mini lathes have two 20T and two 80T wheels in their set, and allows a feed rate of 0.09375 mm per rev to be set, which should be sufficiently fine for most purp[oses.

If you have just one of the changewheels, certainly the driving pinion under the tumbler reverse, you can measure vthe OD in mm, and countbthe teeth.

The formula is : Diameter = (Tooth Count + 2 )/ Module.

Thus a 30 tooth Mod 1 gear would be 32 mm OD

Once you are certain of the Module, you should be able to find replacements. The chances are that the bore and thickness will be the same.

The 1 Mod gears for the mini lathe, (and probably it's smaller sisters ) are plastic, bur Arc Euro can supply metal ones, if you so require. I think that the S4 uses metal gears

HTH

Howard.

Mike Hurley.