Frank,

There are three clues.

The easiest being to look at the gearbox, right hand side. The later ones ( Serial 2501 + onwards) have the leadscrew running straight into the box. The earlier versions had a little housing on the right hand side into which the leadscrew went instead. The gearbox serial number is stamped on that side.

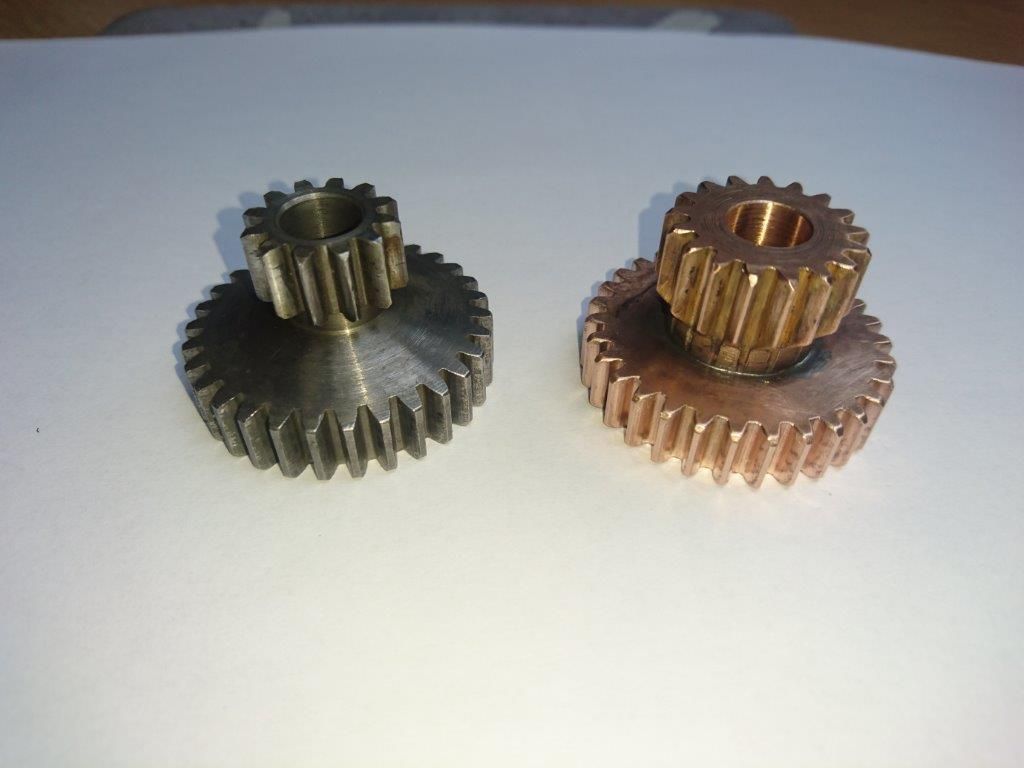

Another clue is the one Simon Williams mentioned with 30/12 tooth gearing in the gear chain. This was to provide a 1:2 reduction before feed to the early gearbox. Later boxes incorporate reduction gearing of 26/52 hidden behind the mounting plate that the banjo fits over; there is a small teardrop shaped window where you can see part of the 52 tooth gear. In the later gearbox the leadscrew is brought right through the gearbox to those reduction gears.

From the date of the lathe I suspect yours is the later version gearbox in which case the table that Roderick Jenkins provides will apply, as will the material in my book

Finally, there is a simple replacement for the lower clamp stud for the banjo that allows it to be lowered, which then makes room for mandrel gears in excess of 34 tooth to be used as drivers, thus opening up a whole world of possibilities in screwcutting.

Regards Brian .

Edit While I've been composing my input, Simon has answered you query, as has KWIL and if you have the early gearbox, then Simon is the man to help you. He did a LOT of work along with the late John Stevenson to get around the calculated gearing values based on versions of 33 and 34 gears having 33.5 teeth and 34.5 teeth!

Impossible of course but there are ways and means!

Edited By Brian Wood on 16/11/2021 11:44:12

Edited By Brian Wood on 16/11/2021 11:45:00

Simon Williams 3.