Posted by Andrew Johnston on 04/12/2017 17:28:24:

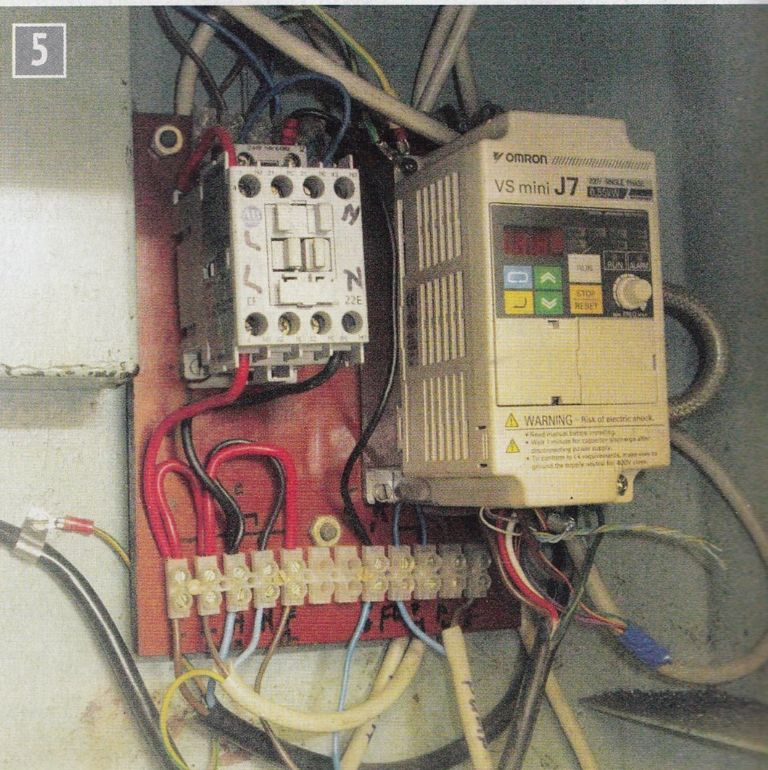

this is a standard industrial setup.

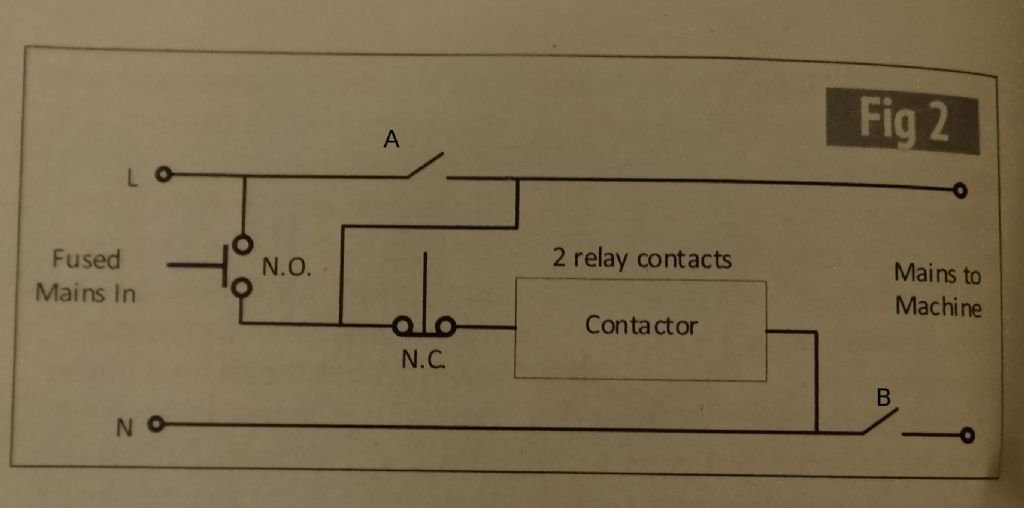

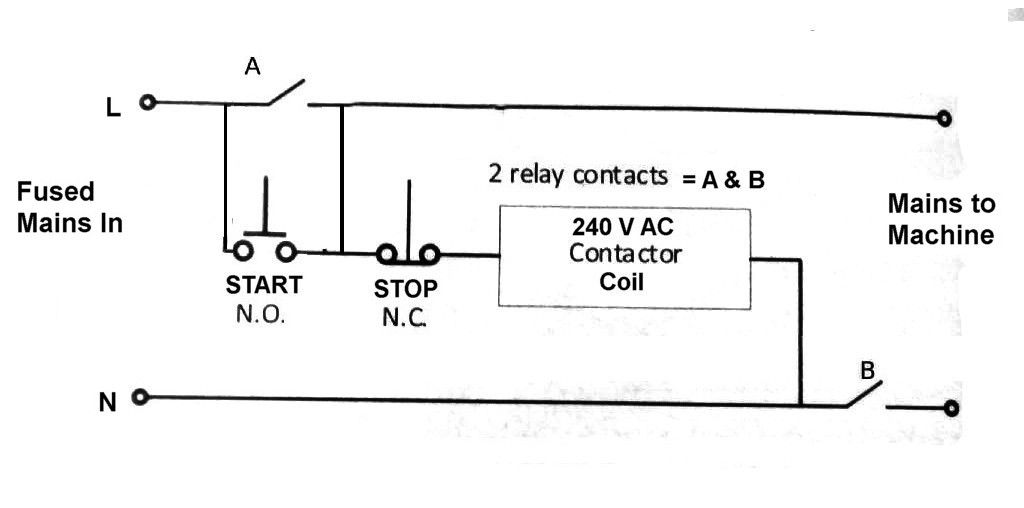

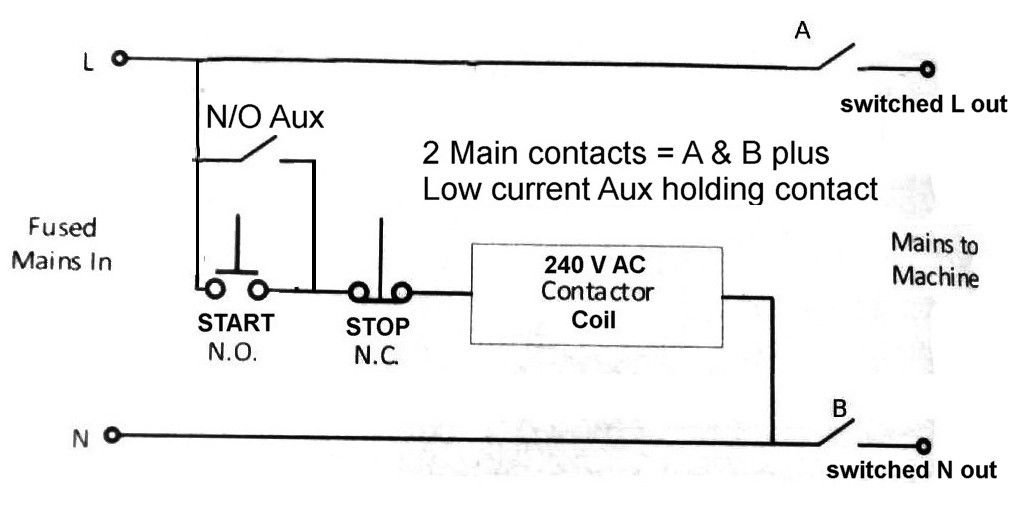

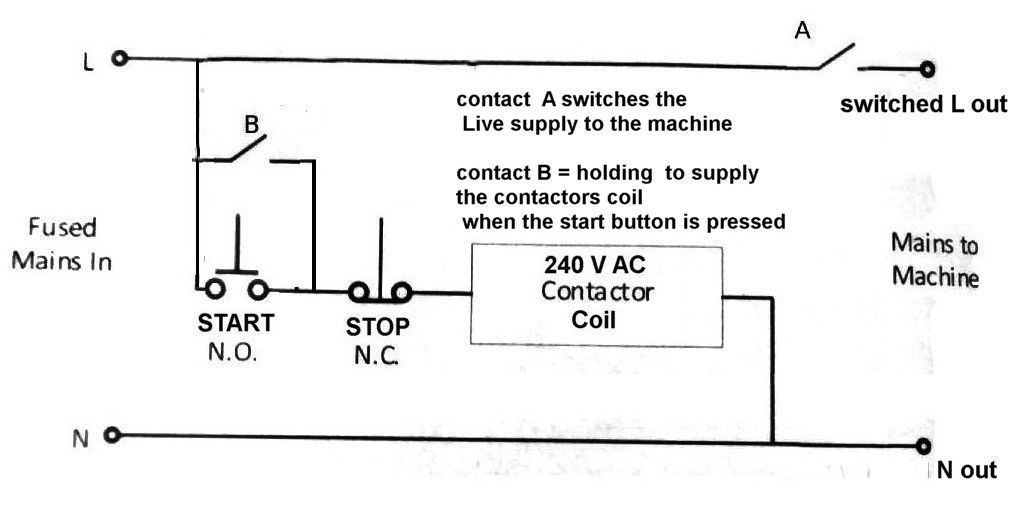

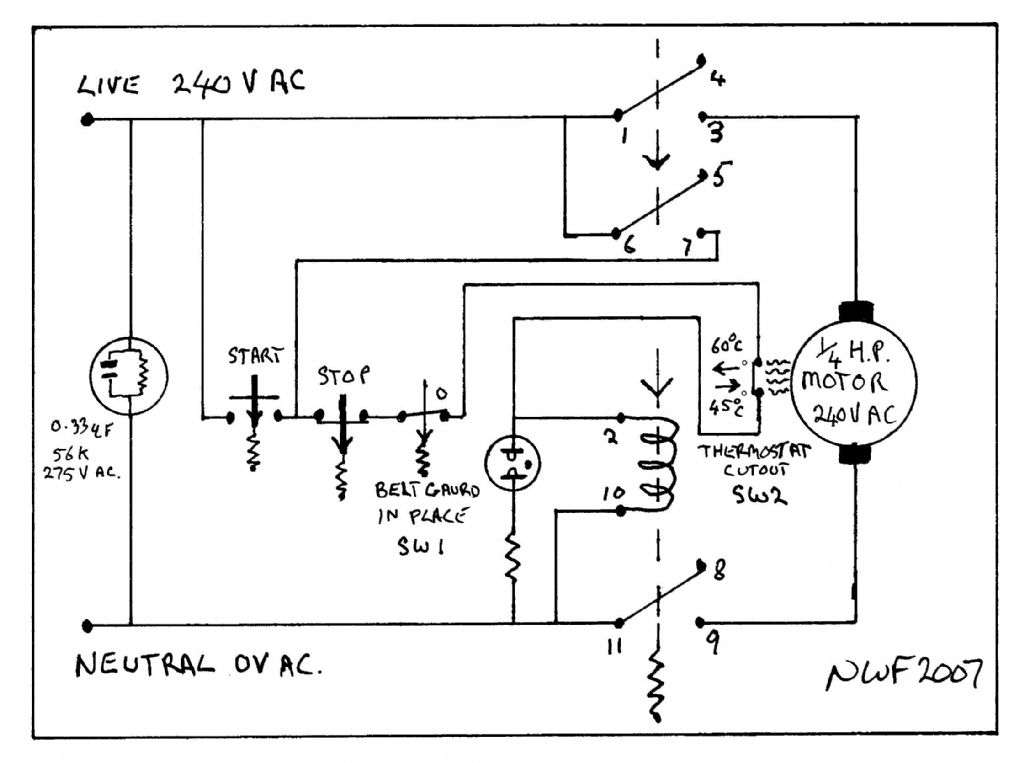

I beg to differ. Good (aka sane) practice would have the contactor coil energised from live by just a push button switch (start) , the latching action by a dedicated normally open contact on the contactor (either a dedicated main contact or an auxilliary contact) connected across it and the release (stop) by another push button switch that is normally closed with an emergency stop (also normally closed) in series from the other side of the contactor coil back to the other supply leg.

The load current for the motor goes from the supply, through the main contactor contacts to the final load and nowhere else.

Sharing the contacts on the contactor between the final load and the control is questionable and 'cheap' but wiring the control circuitry such that ANY final load current passes through the start button, even for a short period until the contactor latches, is beyond ridiculous to suggest as being "a standard industrial setup"

If you are switching a single phase load then three normally open contacts on the contactor are sufficient, (live, neutral and 'control' ) for a three phase load then you'll need four nomally open contacts (three for the phases and one for the 'control' )

Also just using a contactor without any motor overload relay is just plain cheap, many connect direct to off the shelf contactors, cost next to nothing and should, if set correctly protect your motor from overheating.

But single pole switches, even when wired correctly are single points of failure and for emergency stop functionality may, by themselves, not fully satisfy the requirements in an industrial installation.

(spelling!)

Edited By Martin 100 on 04/12/2017 18:37:17

Brian Sweeting 2.