Hi Mike,

The motor normally runs quite slowly. I can't remember if 10rpm is typical or not but it might be. Assuming it's otherwise working correctly, there are two things you can try to speed it up:

(1)

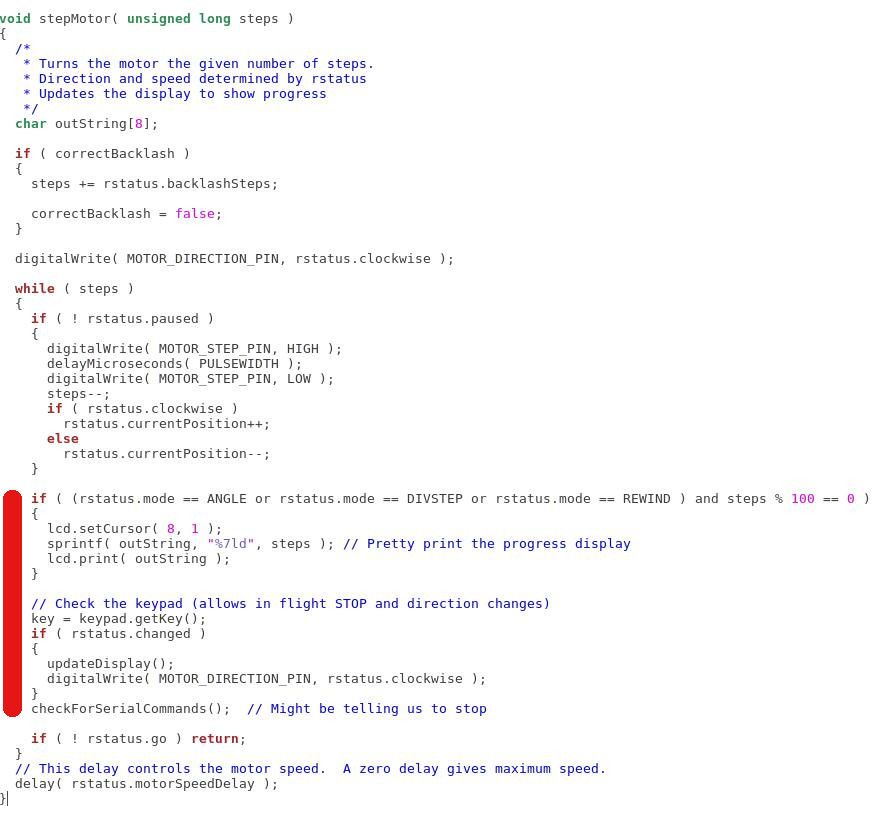

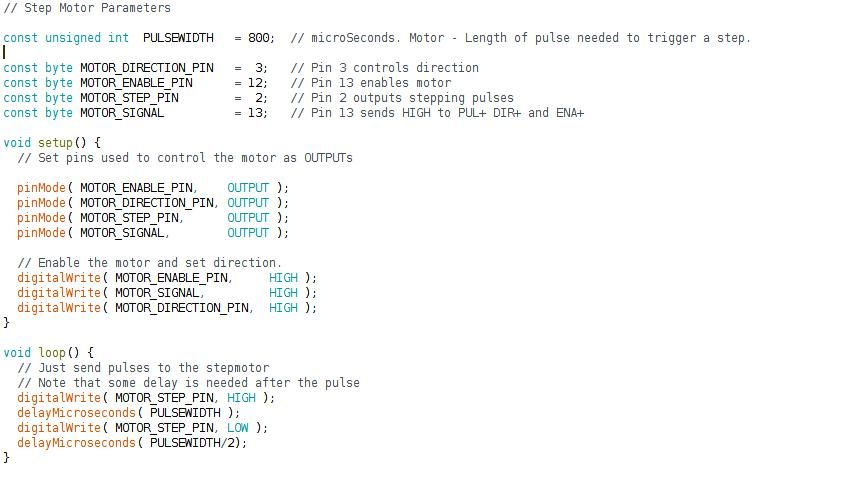

Line 27 of the sketch says:

#define Microsteps 8

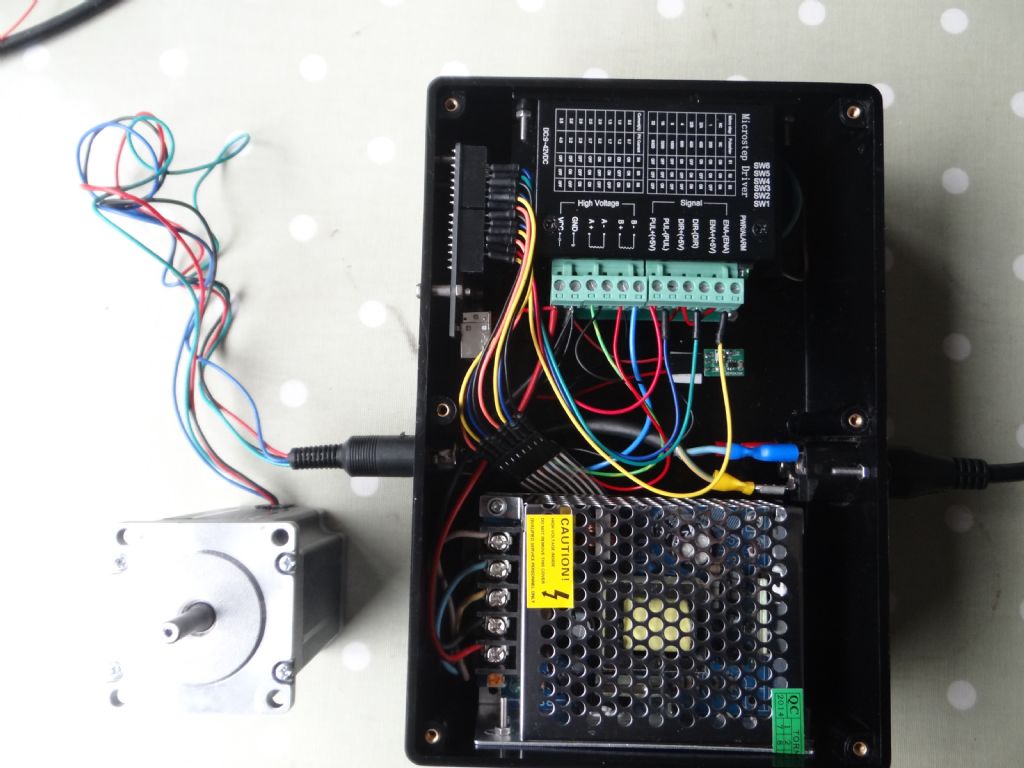

If you reduce the number, the motor will turn faster with bigger steps. Don't forget to alter the DIP switch settings on the controller to match. The downside is loss of accuracy. With zero micro-steps, a 200 step motor is only good for 1.8°

———– and/or ——–

(2)

Line 73 says:

#define pulsewidth 2 // length of time for one step pulse

The #define sets the length of each pulse sent to the motor controller, which is the main limitation in code to the speed. By default it's 2mS per micro-step. You can experiment with shorter delays by changing Line 562 from

delay(pulsewidth);

to

delayMicroseconds( pulsewidth );

Now set the number in the #define pulsewidth statement (line 73) to microseconds, i.e 1500 for 1.5 milliseconds, 750 for 0.75mS etc.

The problem here is whether your motor can keep up with very short pulses. You may need to experiment to find the point at which the motor starts skipping steps and back off from that. Also, the article recommended a 12V supply, and making a stepper motor go fast really needs more volts. A 24V or 36V supply is more likely to drive correctly with short pulses than a 12V PSU. If you do increase the motor's supply voltage make sure the controller DIP switches are set to limit the current pulsed into the motor. Make sure the current limit is less than the maximum specified for your motor.

Hope that makes sense.

Dave

Edited By SillyOldDuffer on 20/10/2017 17:35:46

John Olsen.