Posted by duncan webster on 02/10/2020 23:25:18:

first define some variables

x = distance from centre

Xmax = maximum distance from centre, half the amplitude

w = frequency in radians per second

For SOD case period = 2*833ms, so w = 2*pi/(2*0.833) = 3.77 rads/sec

then x = Xmax * sin (w*t) where t is the time since passing the centre position, and w*t is radians.

If the swing is 5 degrees total, 2.5 degrees each side, and the rod length is 244mm, then Xmax = 244*sin(2.5 degrees) = 10.64 mm, so when the bob gets to the beam breaker

5 = 10.64 * sin(3.77*t), from which we get sin(wt) = 5/10.64 = 0.46, wt = asin(0.46) = 0.489 (remember the 0.46 is radians) and so t = 0.489/3.77 = 0.13 sec = 130 ms.

It causes me all sorts of confusion when clockies talk about a 1 second pendulum when they mean it takes 1 second to go from extreme left to extreme right. Engineers would talk about the period being from extreme left over to extreme right and back again, hence a 2 second pendulum, but I don't suppose clockies are going to change so I'd better get used to it.

Rushing to do something else! First many thanks!

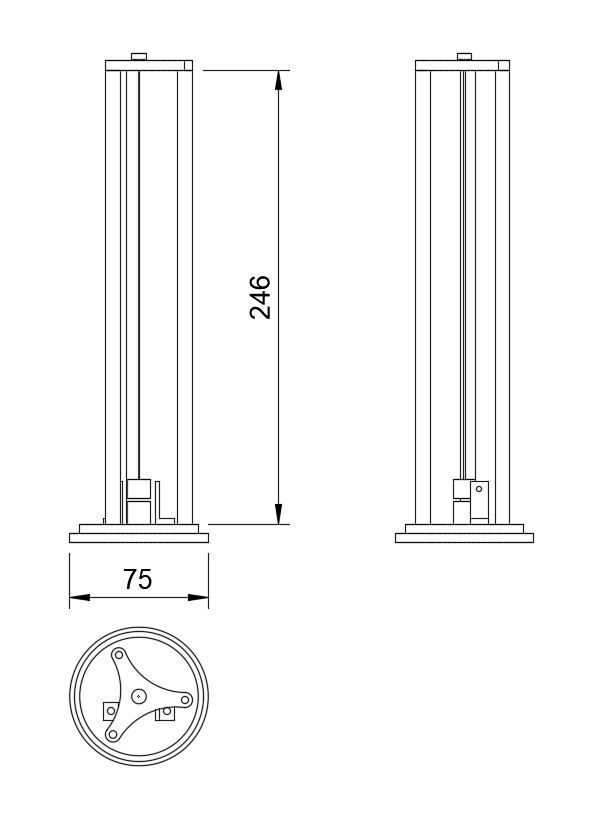

My pendulum is to this design:

Me too confused by clockies halving the period. My ticks are detected on one side of the bob only, so the time is for a full swing there and back. It's about 833mS. So Duncan's assumption it's a 1.6 second pendulum in his calculation was unnecessary – we were on the same page at the beginning.

Another issue is my pendulum is part spring. A conventional pendulum rod is rigid and typically hangs from a short spring at the top. My carbon fibre rod is flexible, and there is no separate spring. I expect the usual formula to be approximately right, but not spot on.

More on this later, but I want to repair the broken pendulum before lunch.

Ta,

Dave

SillyOldDuffer.