I had a look at the GRBL thing today but the family braincell wasn't keen so I decided to go for a simpler approach

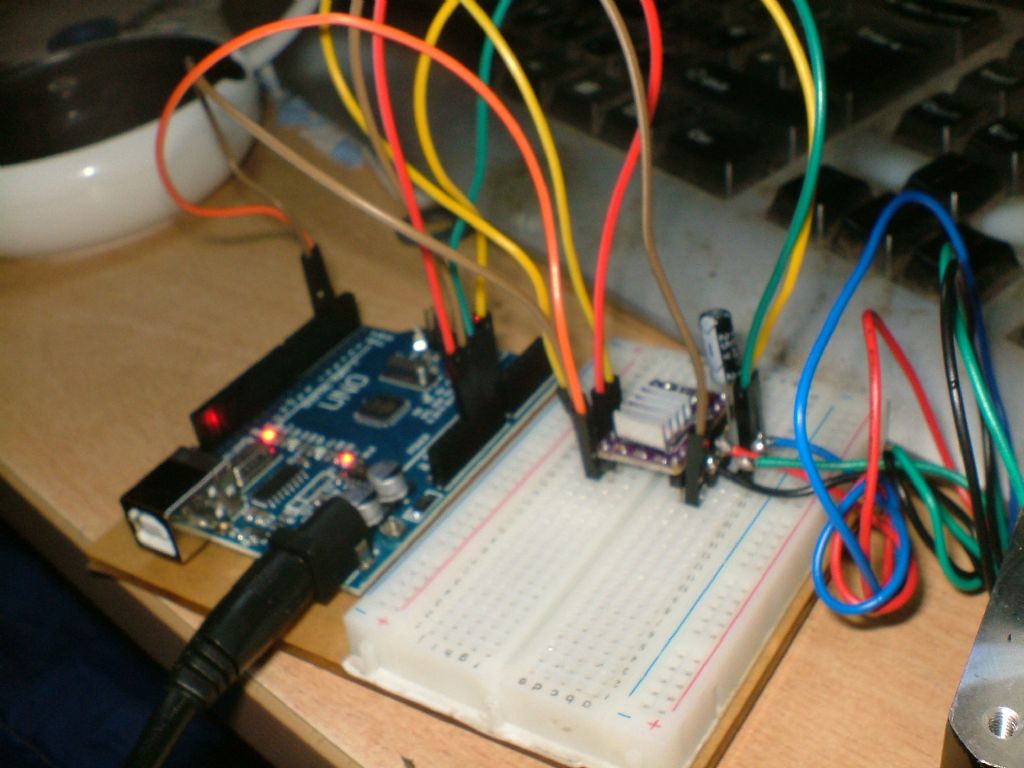

I decided to have a go at running the whole ballgame from the arduino including the NEMA17 stepper

Couldn't find my 12V plug thing… too much housemove stuff but found a 12V jack transformer for an airpump, which was 18V when I put it through the meter… Decided to use it anyway

I used this guys tutorial, which is brill and all I needed

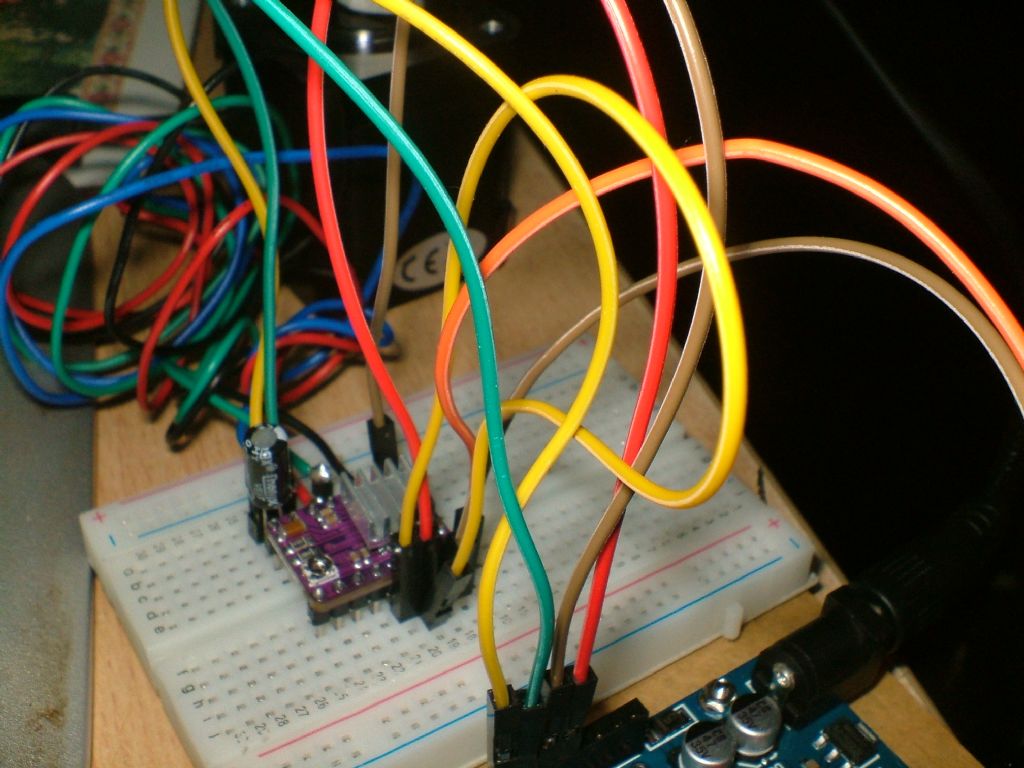

Then mounted the a4988 stepper driver on the breadboard and soldered pins onto the stepper motor wires

I have found those integrated breadboards great for projects

loaded up the library and uploaded his simple routine via the usb, unplugged that and plugged in the 12V jack and waited for the puff of smoke but it ran fine

Luckily I only let it run for 30 seconds before unplugging because I had been unable to reset the pot and it was running a lot of juice. The little heatsink on the a4988 was too hot to touch. I swapped the micro phillips screwdriver head out and used the slotted head to try and adjust it, success! and I got it down to just under 0.5V from its default of 1.5V

This was a huge improvement and limits the juice at 1A (I believe), in any case there were no more heatsink issues, even when I fought it with my fingers and made it work hard

I'm cutting out the 12V adapter on the tutorial schematic and powering it directly from the green and yellow wire on the arduino(VIN and GND) to the main VIN and ground on the a4988, the voltage was 17V (yes I know!) but it at least showed me everything worked

It's pretty darned kewl and has definitely boosted my interest in the subject

Edited By Ady1 on 24/01/2021 00:32:55

Huub.