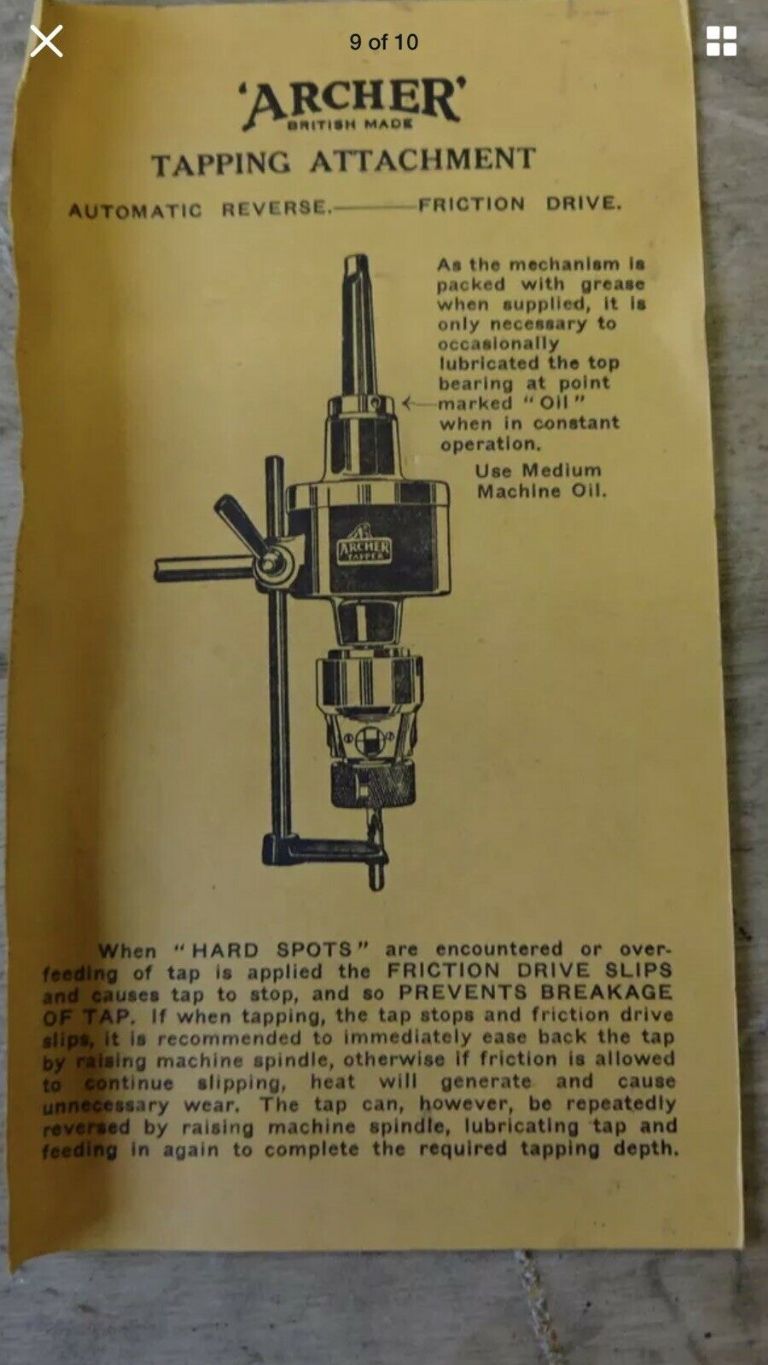

I have a no10 Archer friction drive tapping chuck,with no 1 morse drive,and the instructions this is really just a tap holder with a slipping mechanism and relies on the drilling machine to provide the reverse.it could also be used on a centre lathe or a capstan lathe.Though the machine would have to have the slurry pump turned off ,Its what Peter Ellis writes,its the bottom 1/3 of the tapping attachment, Now the tapping attachment shown in the above post is a true tapping attachment with a reversing gearbox,there was one of these at my first job,a very fierce bit of equipment particularly on Whitworth threads,get it wrong and it would lift quite heavy castings rather than go in reverse,I have the instructions in the box so will write what they say as I do not know how to copy the original on this system

The friction drive is located in the top of the chuck and consists of multiple fibre and steel washers,the compression of these washers is adjusted by means of a castellated tension ring operated by the c spanner provided.

the friction washers must NOT be lubricated.

The friction drive should be set sufficiently firm to drive the size of tap being used.When the tap is fitted ease back the driving tension until the tap just slips when driving the tap,then tighten up the friction drive sufficiently to drive the tap under normal cut.For smaller taps special care should be taken to finely adjust the friction drive so that it slips on the slightest overstrain on the tap . If the tap stops on hard spots or overfeeding and the friction drive slips,the drive should be immediately reversed or the spindle stopped to prevent too much slipping to occur and overheat the clutch the cause unnecessary wear.

on the other side of the instruction sheet there is an underlined note stating DO NOT LUBRICATE THE FRICTION BOX

Its a better non slip way of holding a tap in the lathe tailstock than in the Jacobs chuck which always slips,though I would still use the lathe clutch to stop the tapping op particularly on BA taps ,relying on the clutch to slip may result in tap breakage ,I just use mine as a tap holder and not rely on the slipping clutch.

As i stated previously I have worked with the full reversing attachment ,though I much preferred another make of tapping attachment made by Pawson this had a lot softer clutch and reverse mechanism and was a lot kinder to the smaller taps

Peter Ellis 5.