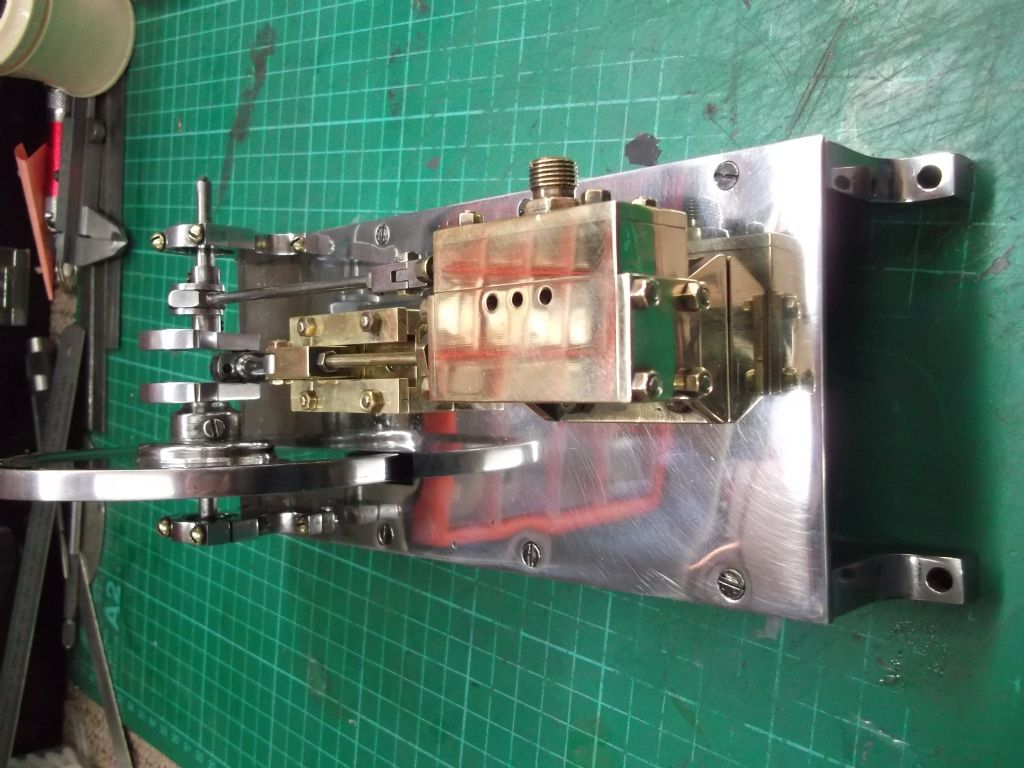

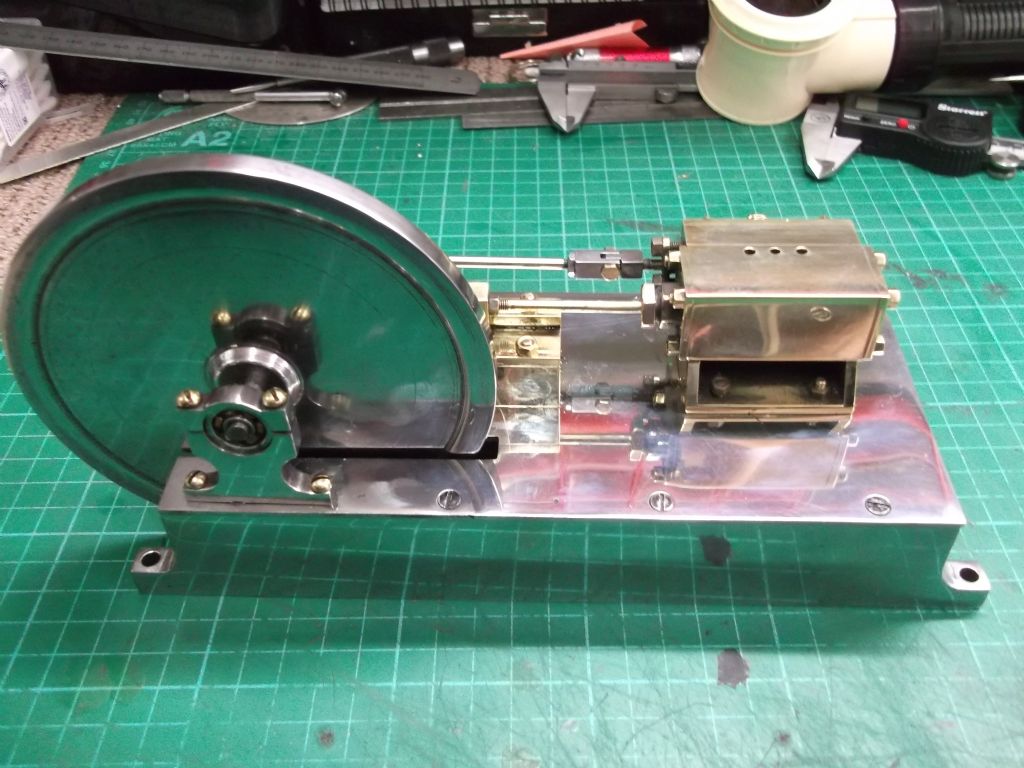

The 'Mill Engine' design has been around a long time: it's very similar to the 1901 Thompstone Engine Jason is reinvigorating in ME at the moment. (Part 1 is in 4662.) Pretty much the same layout as Stewart Hart's PottyMill, and one of my old text-books describes a full-size engine of the same type. A sort of small simplified mill engine, no reverse, or condenser, slide valve driven by an eccentric, only a couple of HP, plain build, and presumably intended for a small enterprise mixing dough, making butter, driving a laundry or whatever. I believe the type was very common before electric motors took over, and they make good model – not too difficult in basic form for beginners, castings or fabricated, and can be made more elaborate if required. For example the PottyMill's plain Aluminium cylinder is mounted on a block, whereas Jason's Thompstone has turned brass feet inset into a Bronze cylinder with tasty decorative bands.

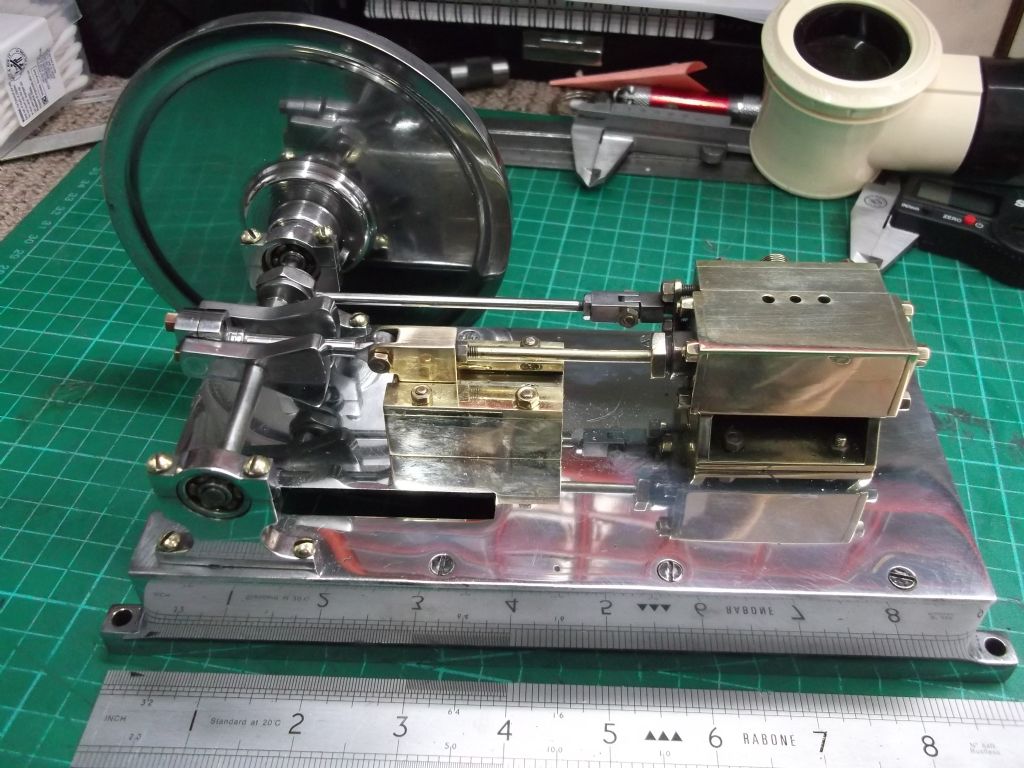

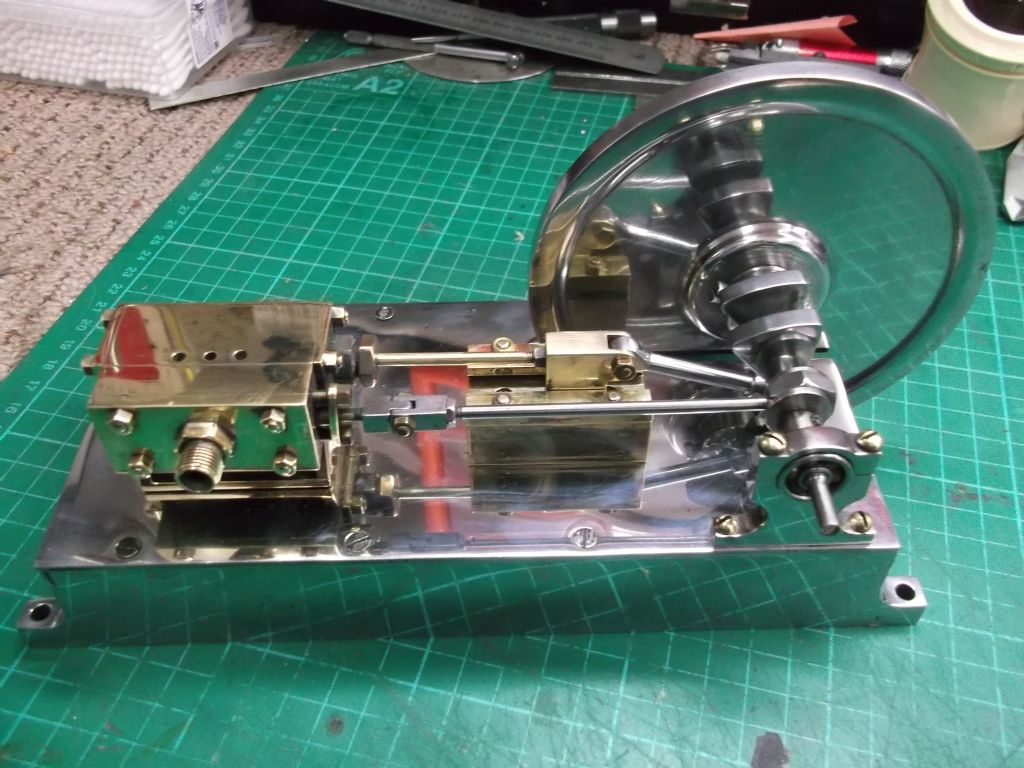

The polish and fine finish suggest the engine was made by someone who had plenty of spare time. The absence of spokes suggest he or she had access to a lathe, but not a milling machine, and perhaps decided to tackle them later. I agree the flywheel should be in the slot, which suggests the engine has been assembled incorrectly. Possibly someone made it, got it into running condition, and then passed the engine on to a new owner who beautified it, but didn't have the facilities to cut spokes, quite understand the flywheel, or realise the slotted-screws were temporary.

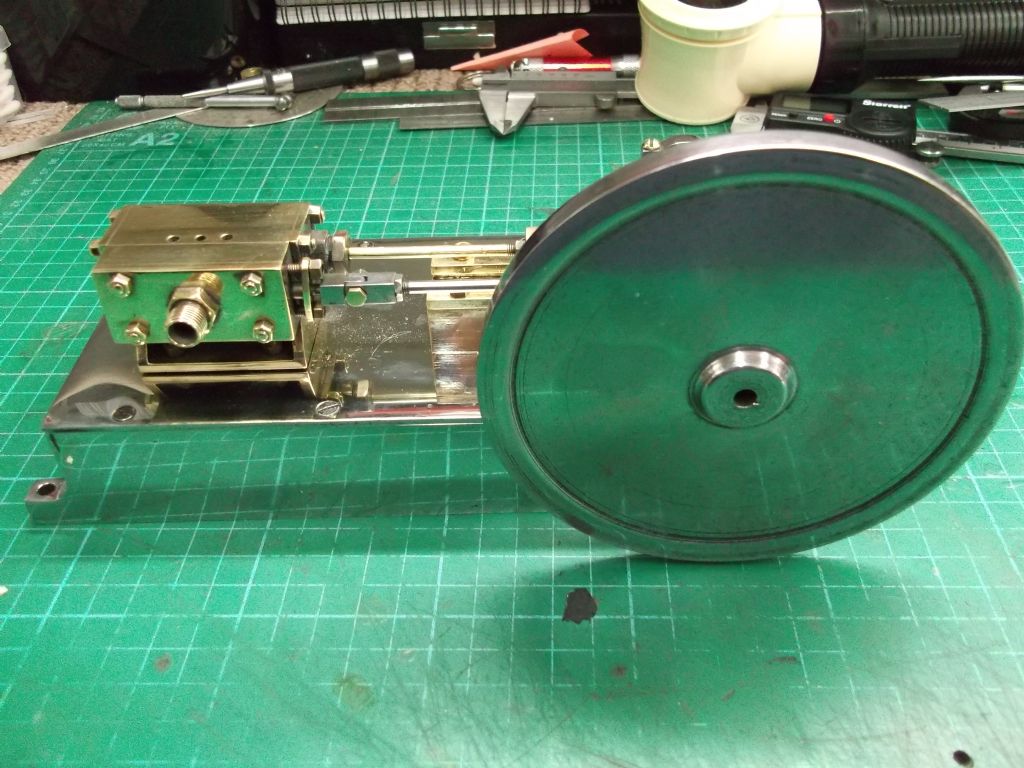

My first PottyMill is rough because I built it to exercise my weak machining skills: it wasn't intended for show, and the result is purely functional with many unfixed blemishes. Maybe when I'm dead it will be refurbished and sold in a glass case as an attractive antique, claimed to have been handmade by James Watt in 1760…

Dave

JasonB.

JasonB.