I need to remove six off 4BA countersunk socket head fixings to dismantle a camera tripod (to cure a damping fluid leak).

I have good quality Allen keys but all six screws have resisted all the techniques that I know of or have used successfully previously. The problem in this case is the limited height above the screw head.

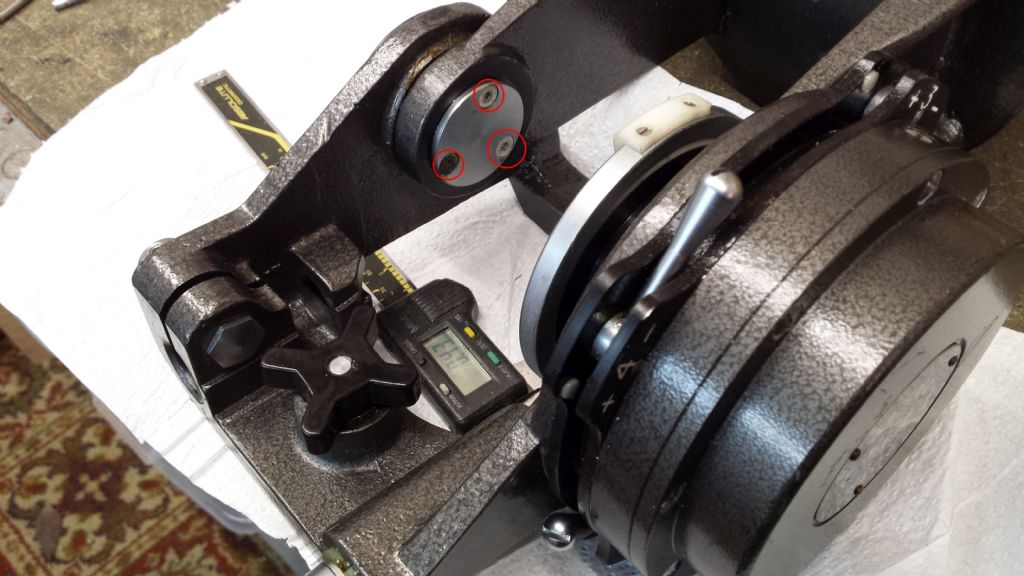

There is about 65mm between the two inside faces both of which have three fixings that hold the stub spindles. With extended drill bits the three fixings on one side could be drilled out but the drill would be about 20 degrees off axis so I'm not likely to have much success.

On fixings with clear access I have drilled out seized screws down to 8BA without sacrificing the tapped hole so 4BA are not normally a problem.

I do not have any welding equipment but I'm not sure how much damage might be done to the paintwork etc if a stud was attached to the screw head.

The six in this unit are standard steel Allen screws, ringed in red in the pictures. (Caliper is just for scale)

What I think I need is a miniature right angle dremel type tool to grind off the heads but I have not seen any tool small enough to fit in the gap.

Ian P

Mikelkie.