It sounds like a good buy. A few years ago I instantly snapped up a good old one when it appeared at work on the back of a trailer with a load of other gear. Its a 1cwt size with its original cast base and has had little use, a nice thick slice of tree trunk would be nice to sit it all on.

The description by Jeff of how the better ones are made is very interesting. I have seen the small cheap ones he also mentions, are they around 5 – 10 kg?

A bit larger than that were the ones made by Record, are they still available? These were very nicely cast but just out of grey iron I think. Does anyone have one of these that they have whacked the hell out of that still survives?

I used to visit the three 'Tabwell Tools' shops in Bakewell years ago. One sold machine tools by Record, myford and Emco amongst others, another was for modelling and crafts and the third sold power tools and was full of Record products such as vices and the anvils. I think the shop owner was also the owner of Record at the time.

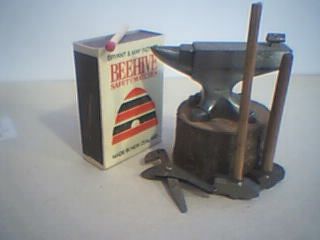

I have two other anvils, one is a tiny but perfectly formed one by Record, the other is one I cut and shaped out of old railway line.

Neil Wyatt.

Neil Wyatt.