Buffer

As Martin suggests for finish turning but to get there many other methods may suit, my method as follows.

1.Mount the blank in a 3 jaw chuck and face the surface, only remove enough to clean up.

2.Turn job around and face other side, Drill, bore and ream a 1" hole through the part.

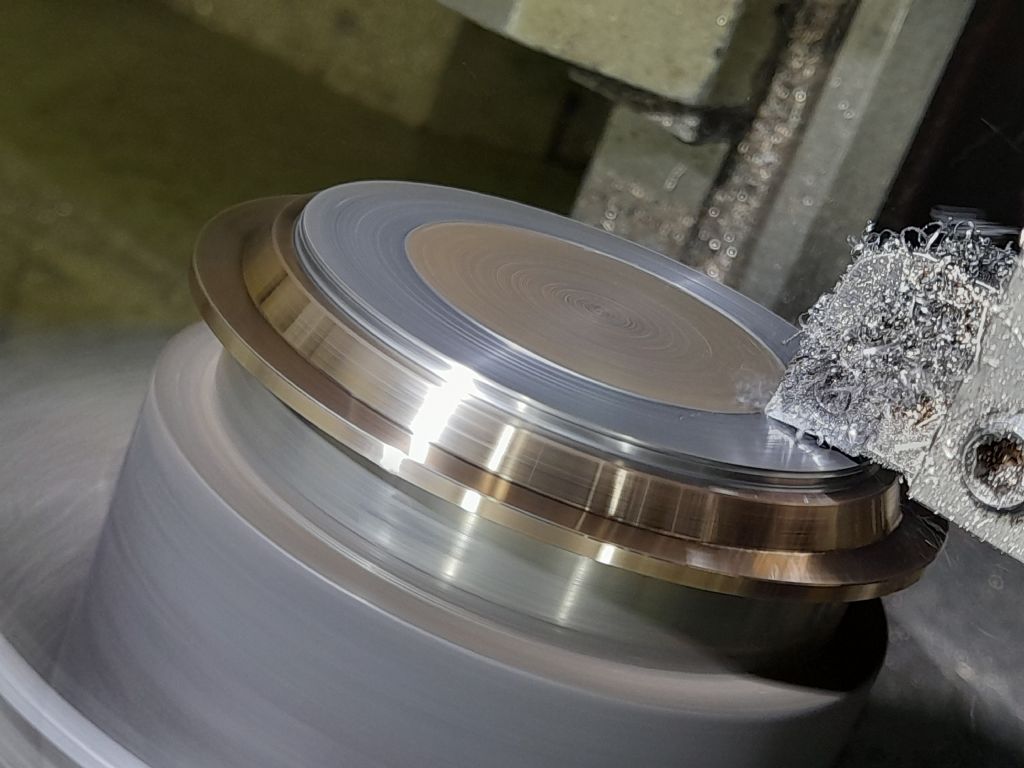

3.Fit a known accuracy 1" mandrel to the lathe and secure the blank with a large diam turned washer and nut.

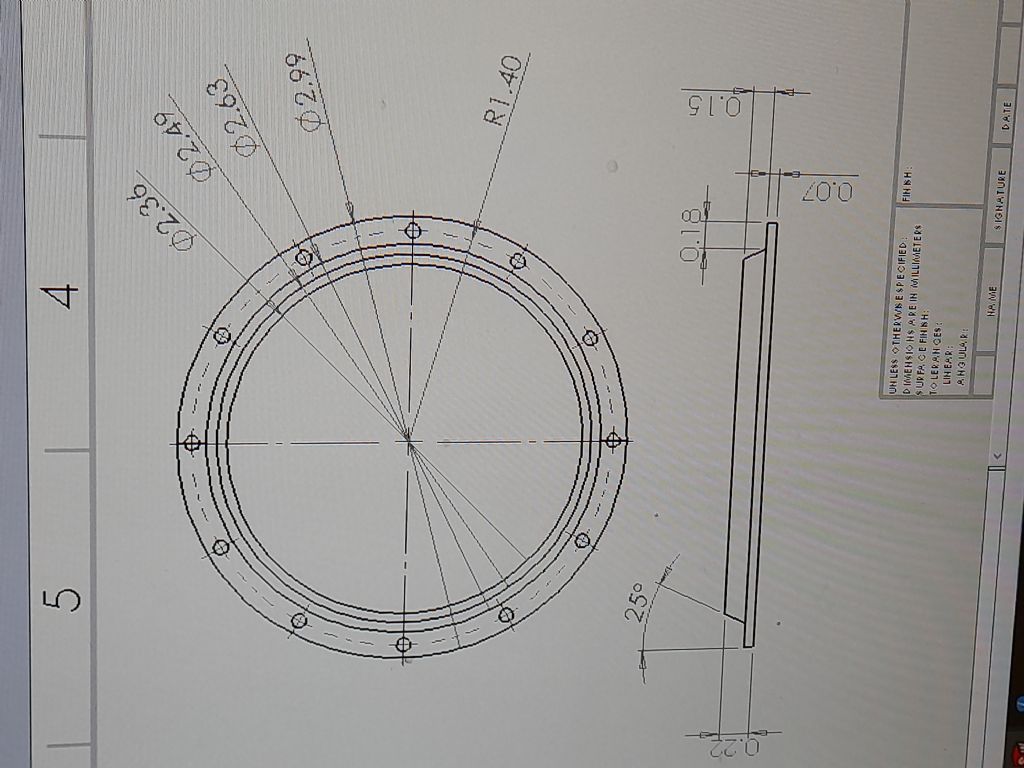

4.Turn OD to 2.990" diameter.

5.Turn the 2.630" diameter to leave .070" thick outer flange.

6.Use the topslide set to suit the 25 deg angled cut and turn the taper.

7.Face off where possible to leave .022" thickness to part.

8.Remove job from mandrel and mark out and drill the holes shown in the flange.

9.Fix the part via the holes in the flange to a piece of ply/MDF bolted to a faceplate and faced/bored to suit the flange diameter to prevent movement.

If no faceplate available:

If absolute concentricity is not required hold the work by the flange OD in a 3j SC chuck and bore to 2.360" diameter, don't overtighten the jaws or the diameter will be distorted.

Alternatively for good concentricity of the bore use a 4jIND chuck but risk of distortion still present.

Emgee

John Reese.