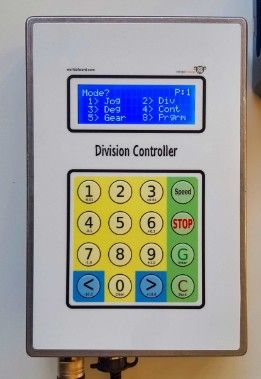

Another stepper motor powered rotary table

Another stepper motor powered rotary table

- This topic has 24 replies, 13 voices, and was last updated 13 January 2023 at 16:37 by

ianj.

Viewing 25 posts - 1 through 25 (of 25 total)

Viewing 25 posts - 1 through 25 (of 25 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Bridgeport ways and wear

- File backup to external hard drive, incremental etc?

- road registration and traction trailer.

- Old plastic handled screwdrivers

- Chester Champion, warco ZX15 drawbar

- Square end on round stock – Milling?

- Twin Engineering’s heavy mill/drill quill removal

- A Persistent Scam

- Readability / clarity in new combined magazine

- Herbert B drill – a question and a curiosity…