Rod, the short notes in the original article do mention "mandrel drawn" brass tube so sounds like something similar.

At this stage I was enjoying the building so much that I did not take as many photos as I could have done but there is nothing too special about most of the remaining parts.

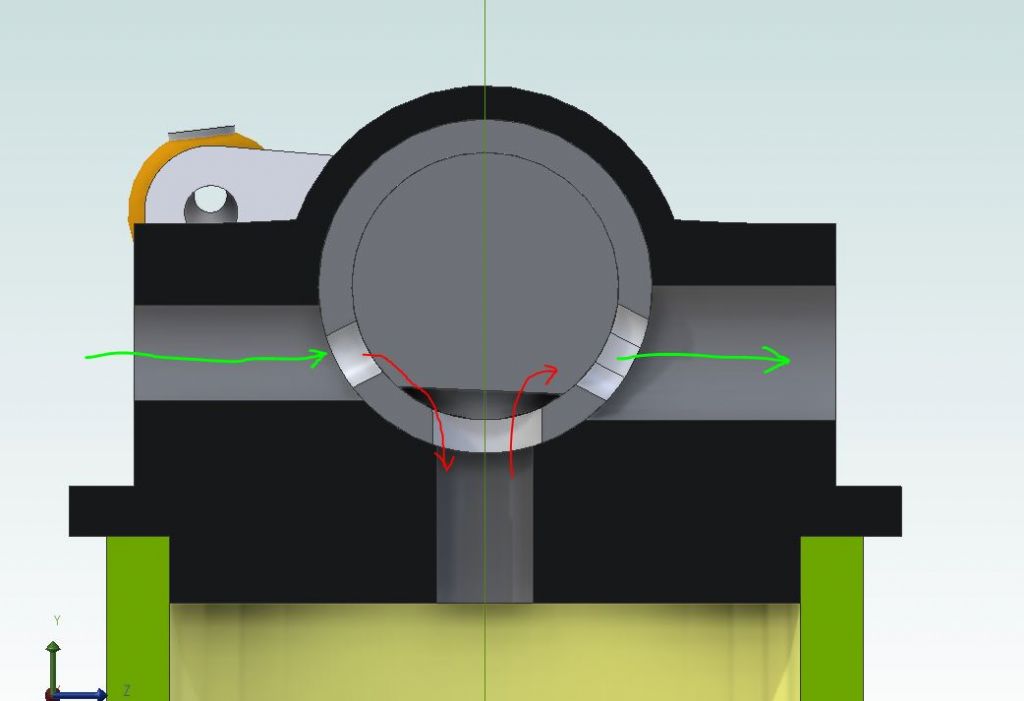

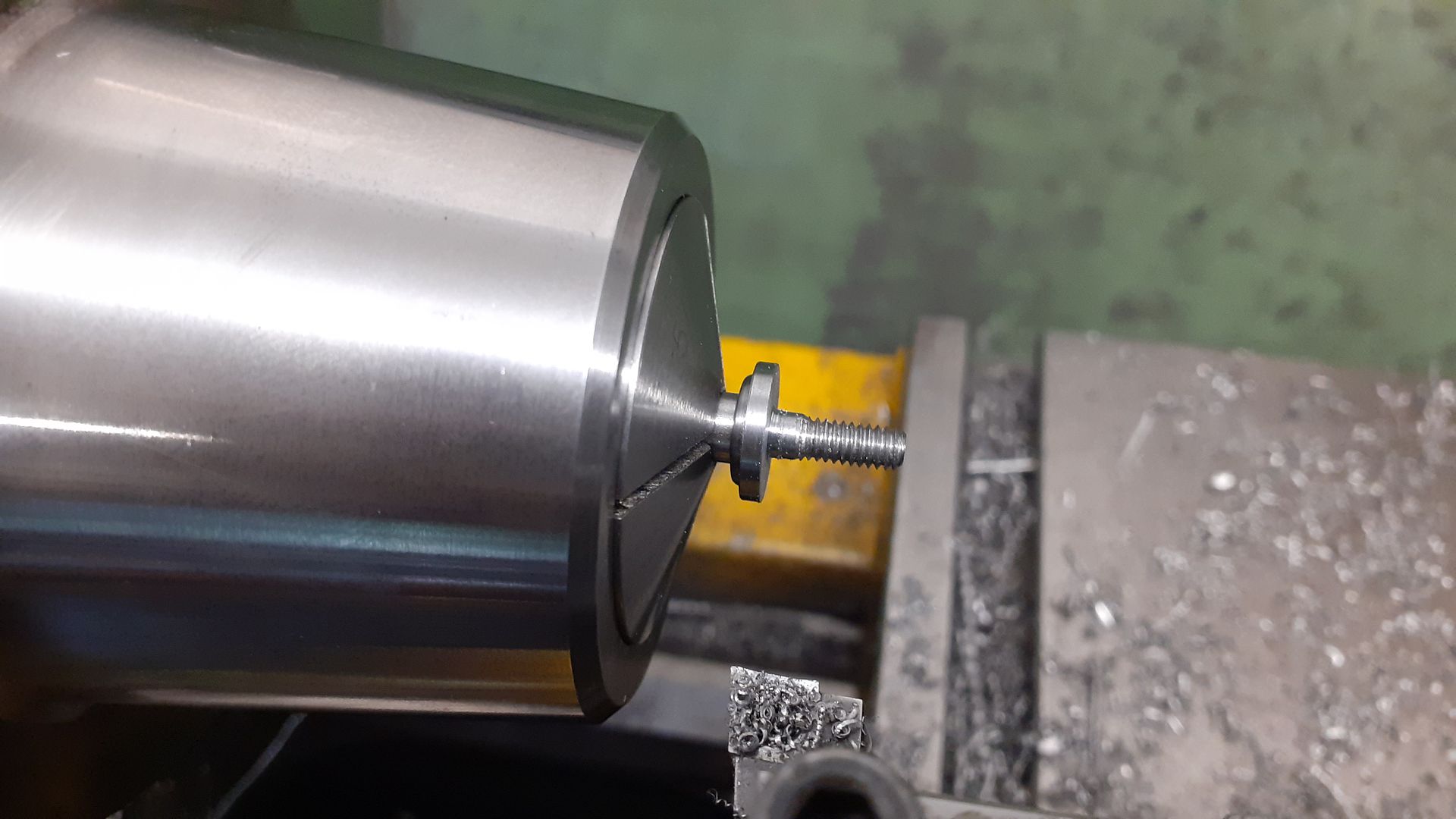

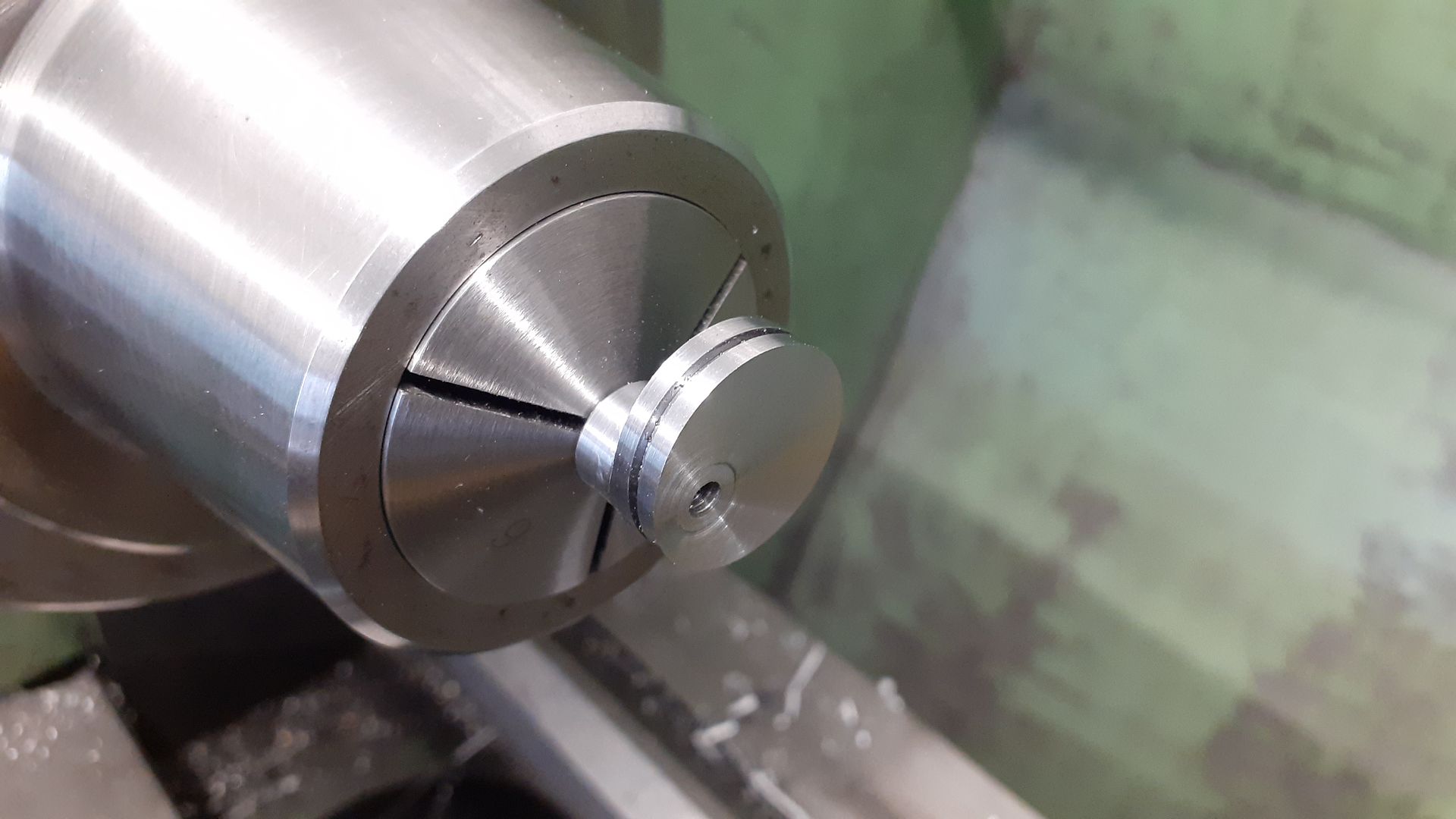

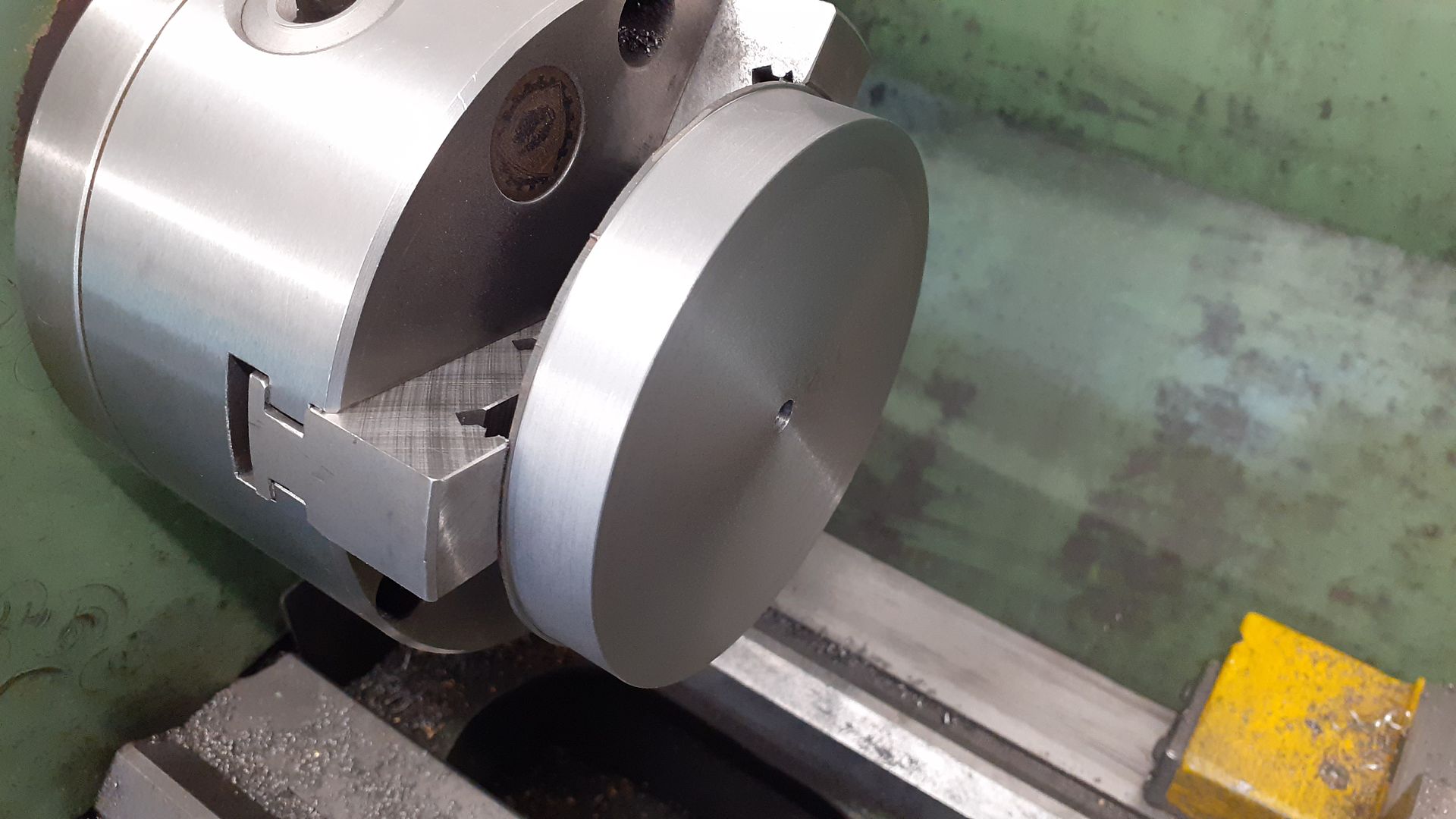

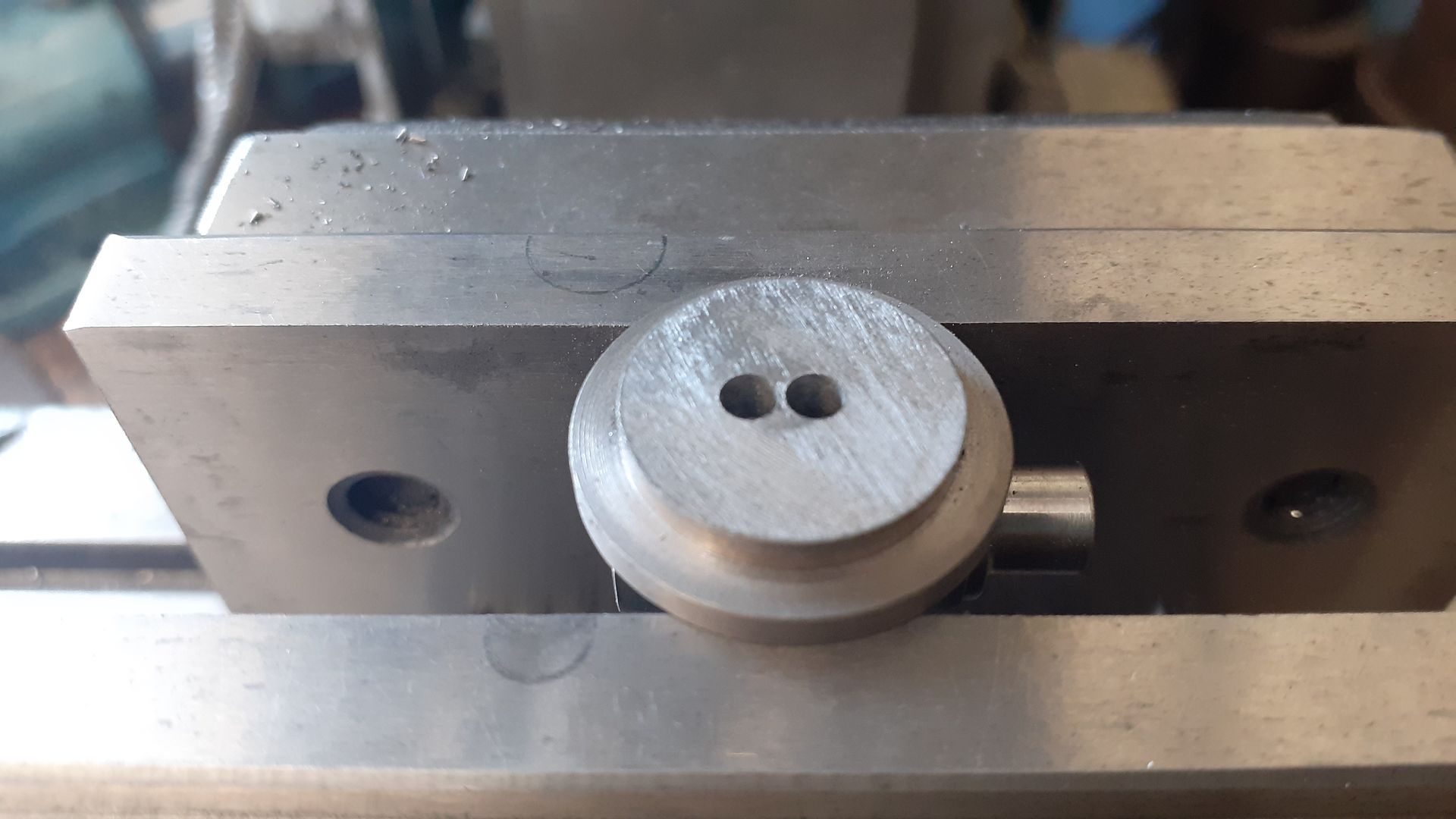

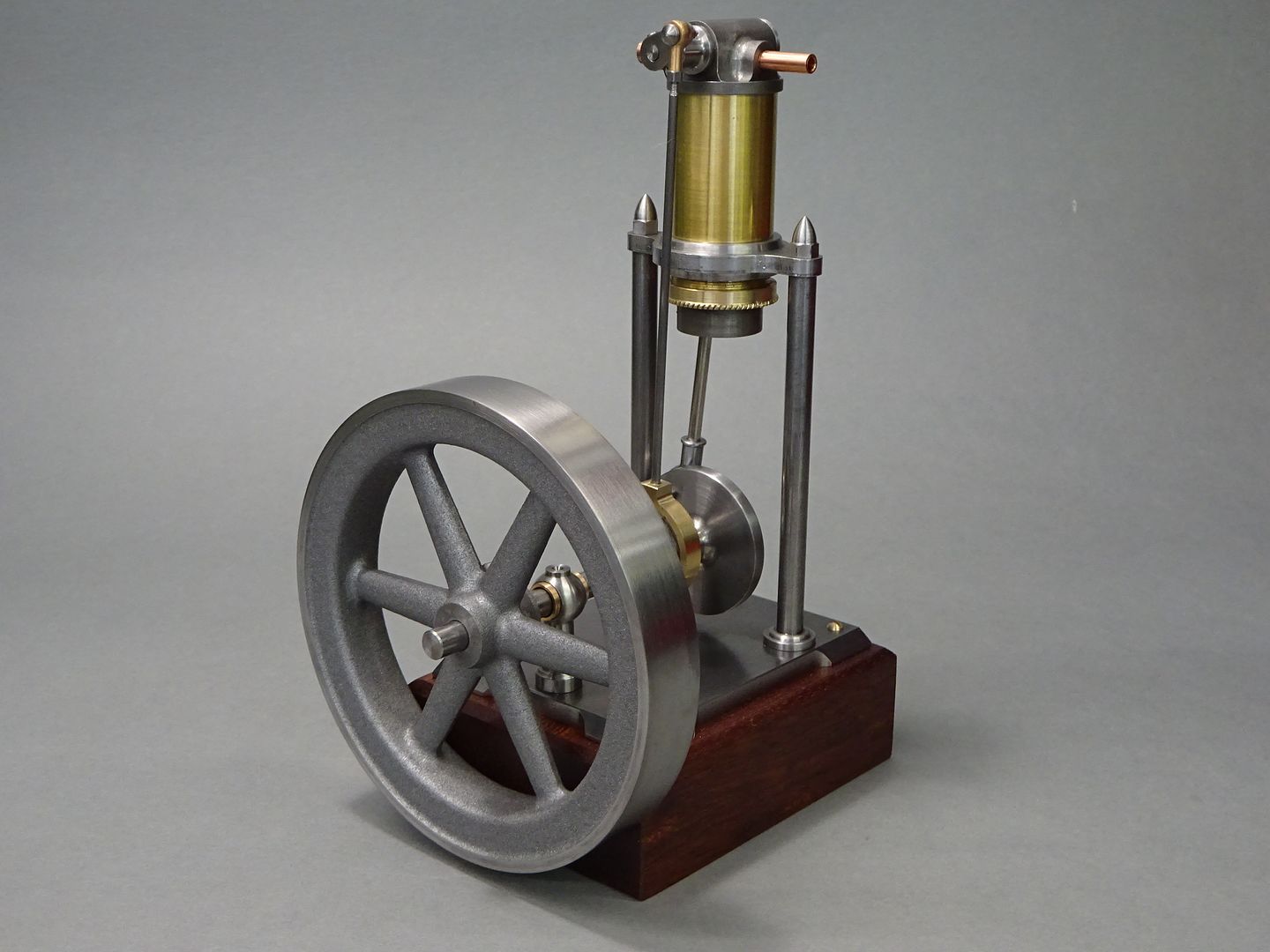

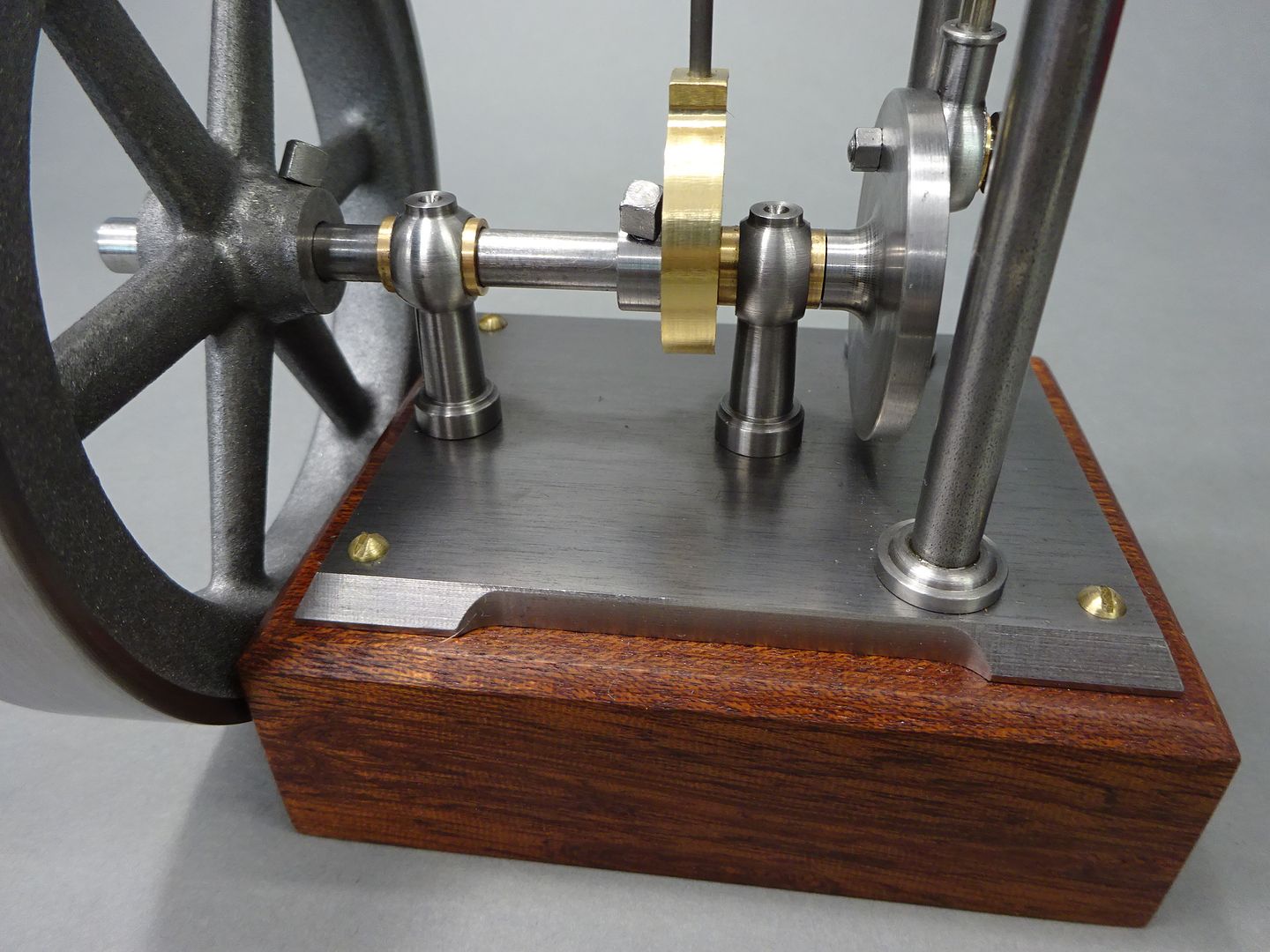

The crank disc was roughed out and then a RCGT 06 button insert used to finish the back edge and give a nice large fillet to the protruding boss and then the hole was spotted, drilled 5.8mm with a stub drill and reamed 6mm before sawing the disc off of the piece of steel bar. It was then Loctited onto a length of 6mm precision ground mild steel and once that had gone off the front face was turned to final thickness thus ensuring the face was perpendicular to the shafts axis.

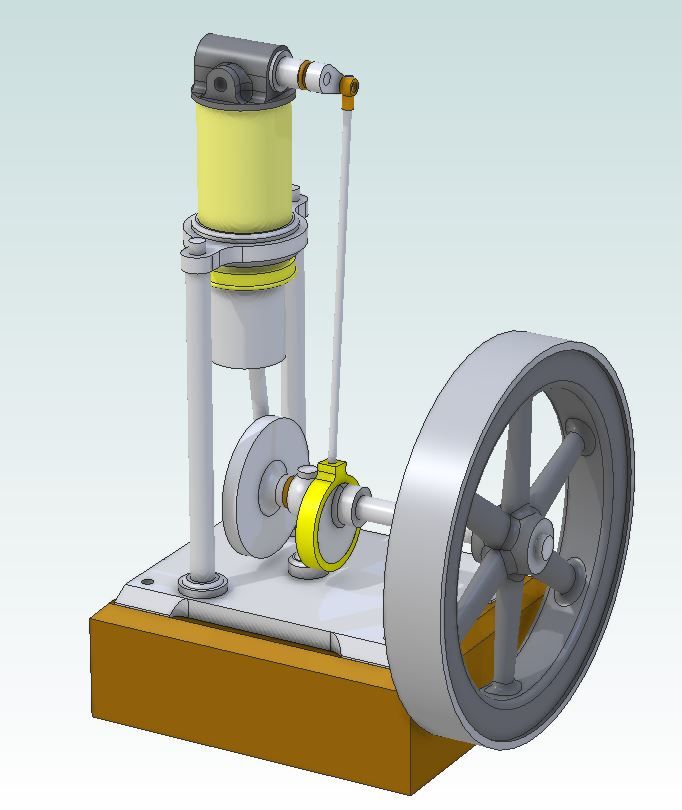

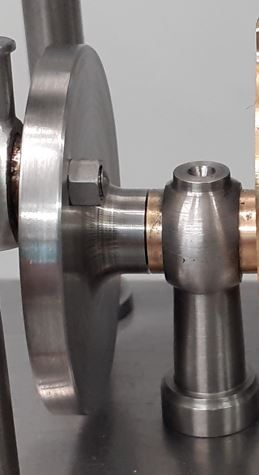

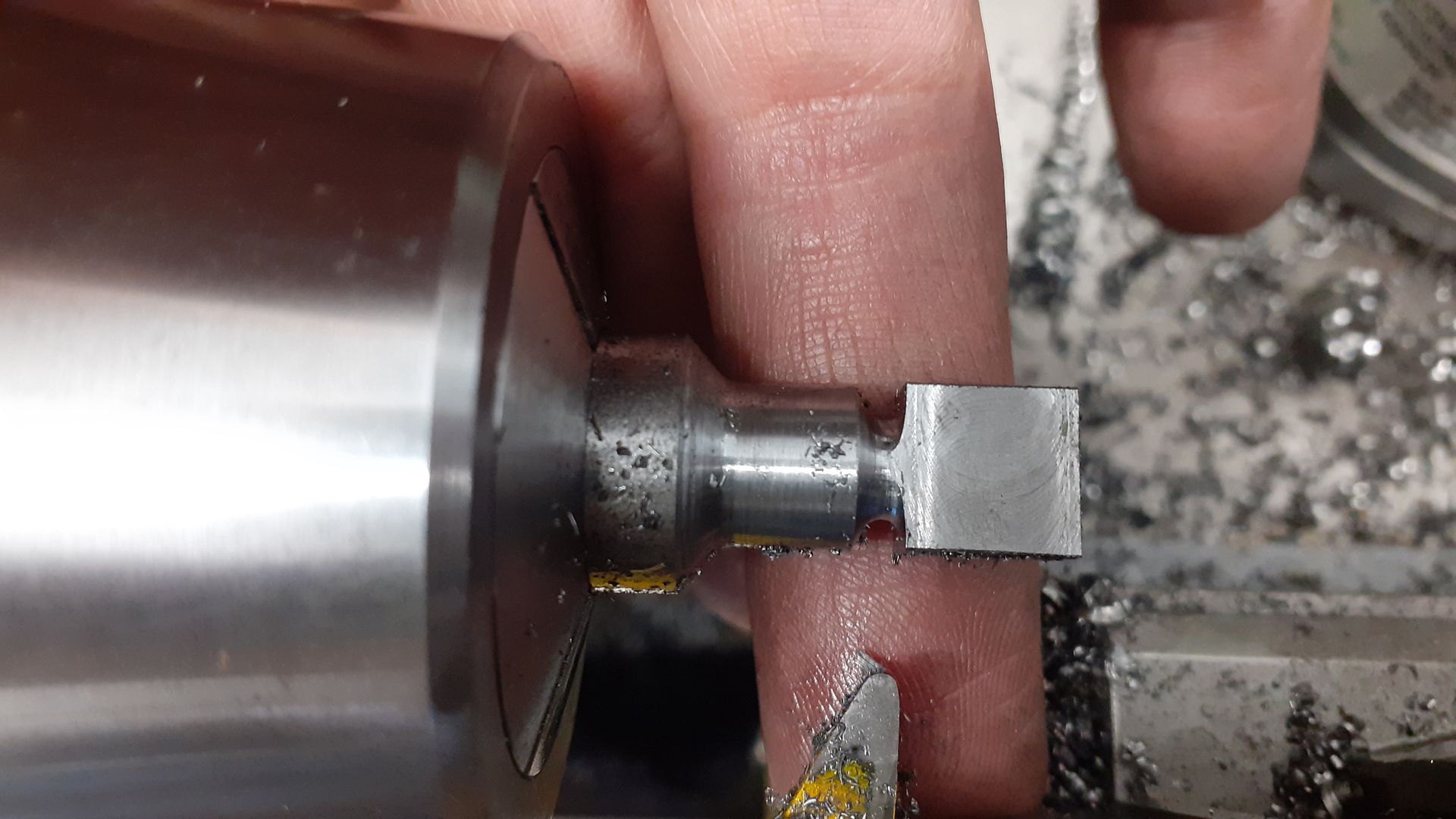

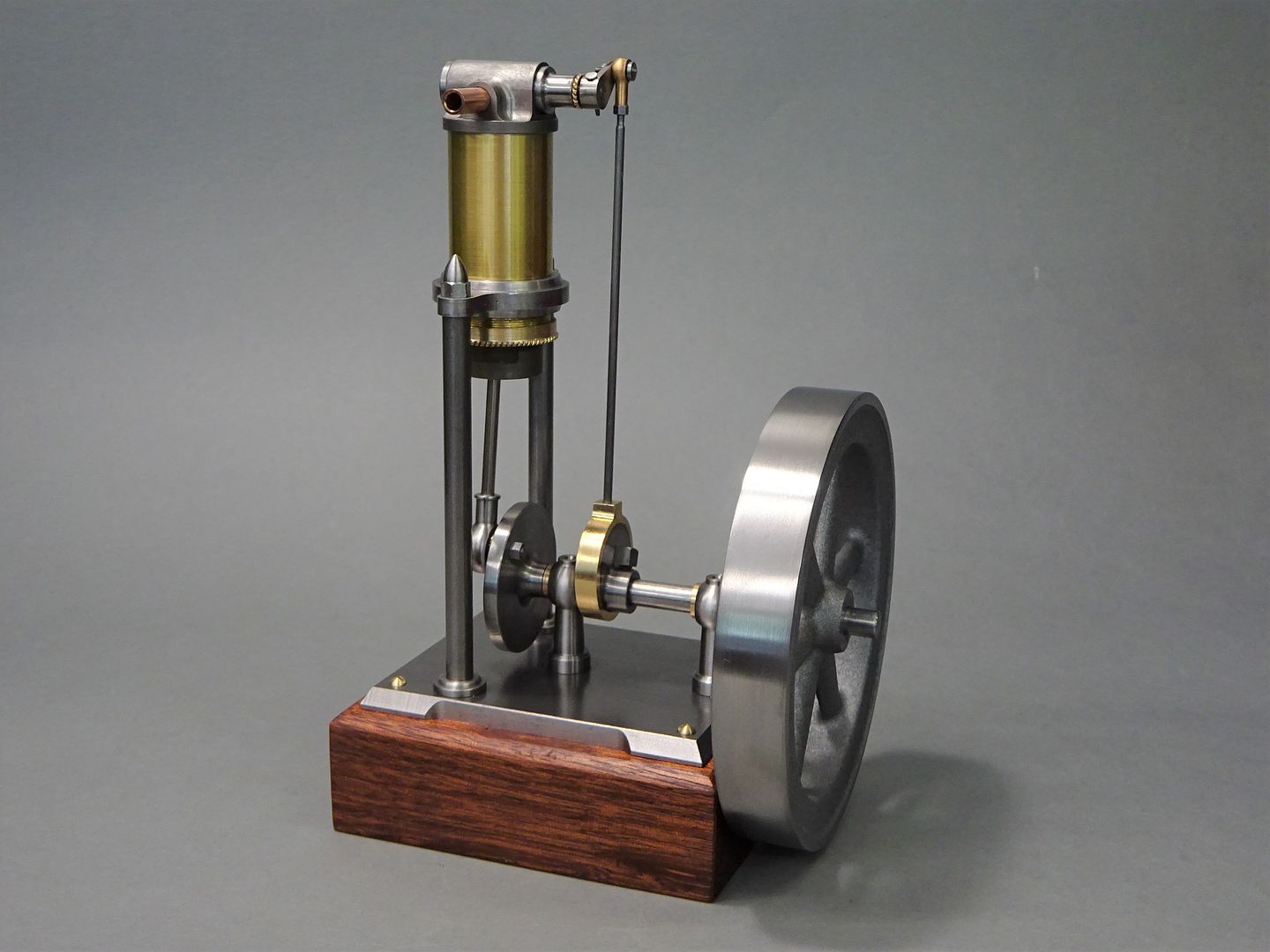

The bearing supports that can also be seen in the photo above were turned from 12mm leaded steel using a ball turner to form the top and a 1mm radius tool to turn the tapered column so it blended in nicely to the ball. Moving over to the mill 3mm was taken off opposite faces and an 8mm hole drilled and reamed through to take the bearing. Back into the lathe a parting tool was used to form a 3mm dia spigot that could be threaded once cut off for a nut to hold the support to the base

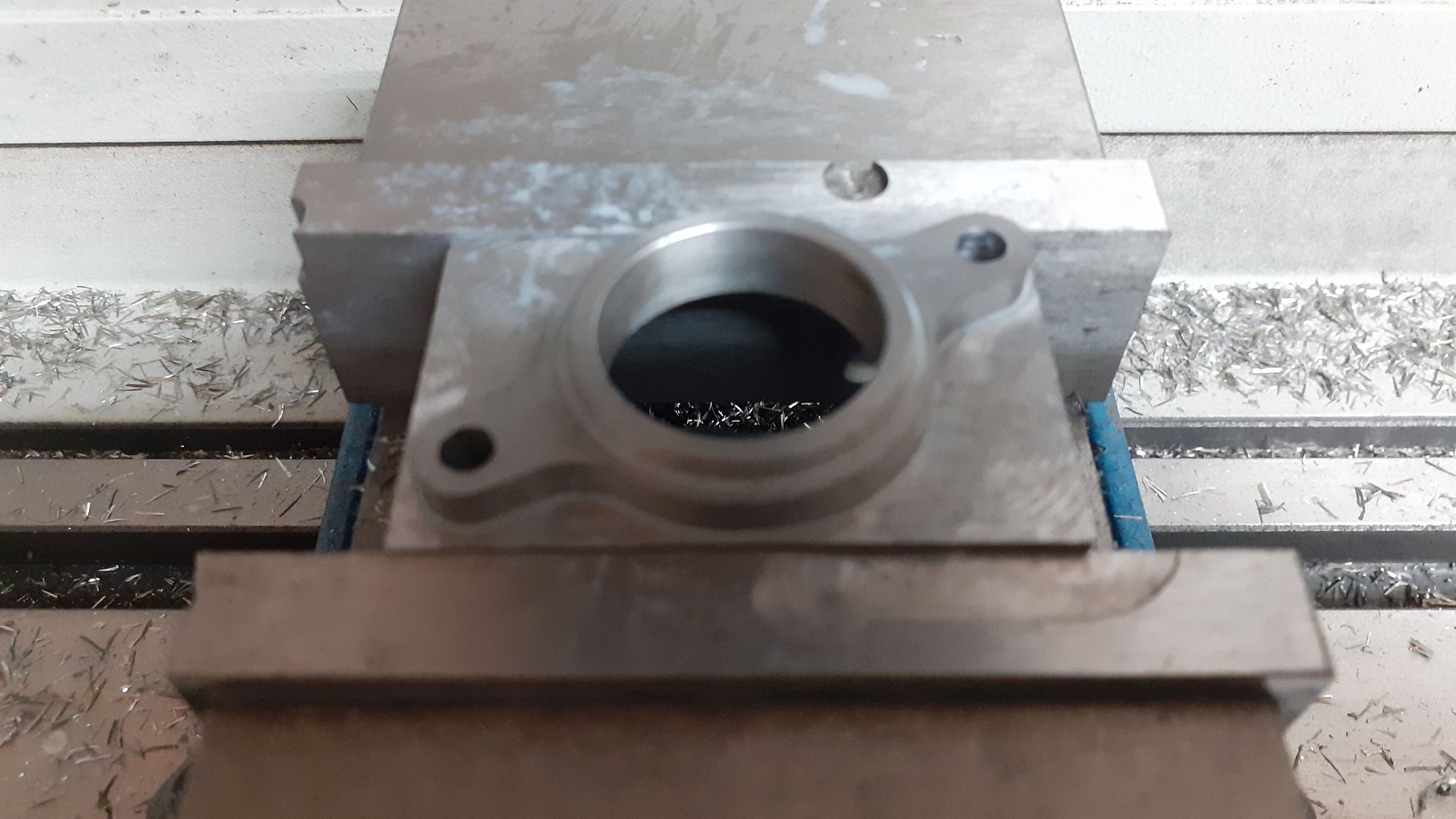

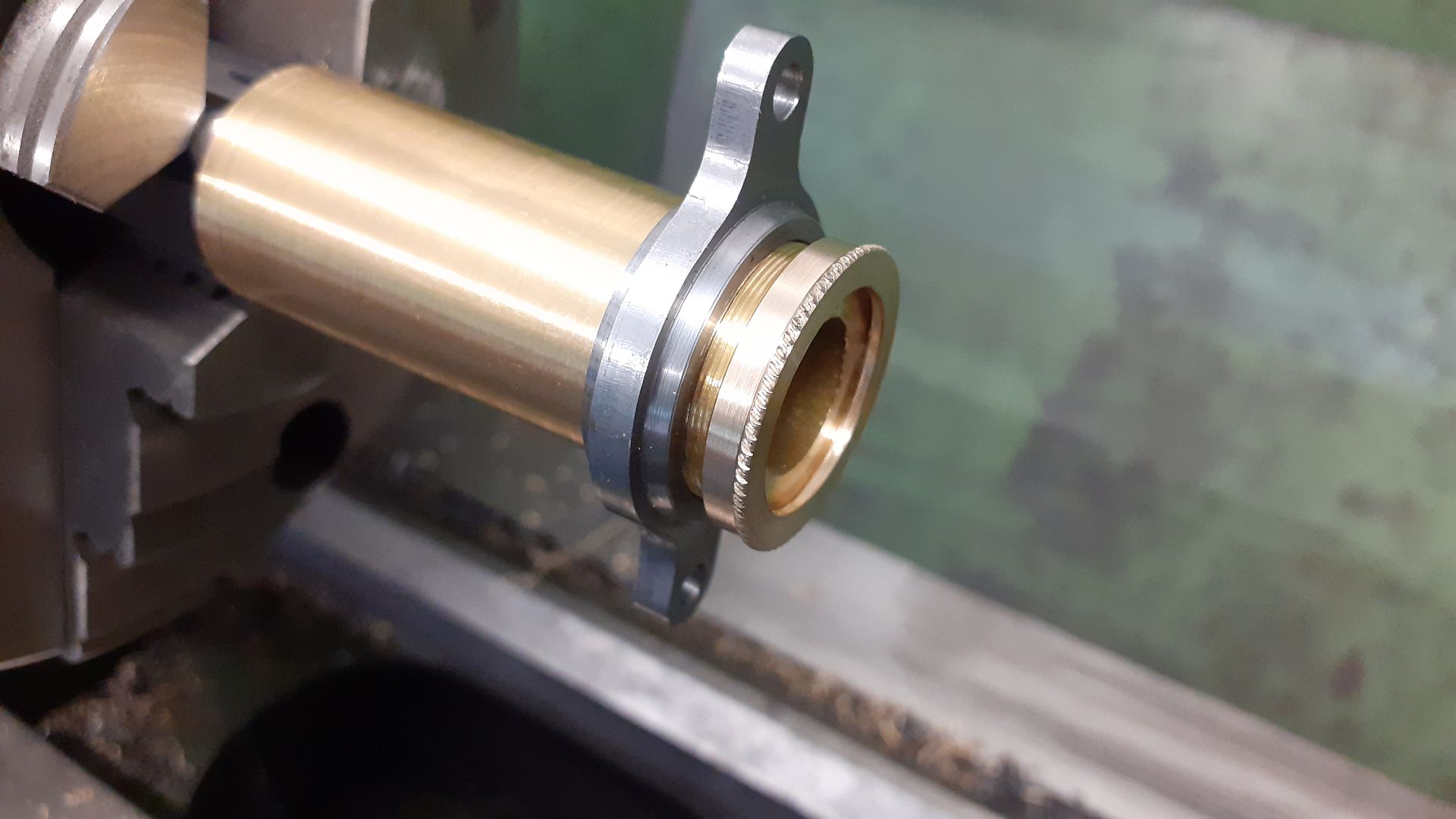

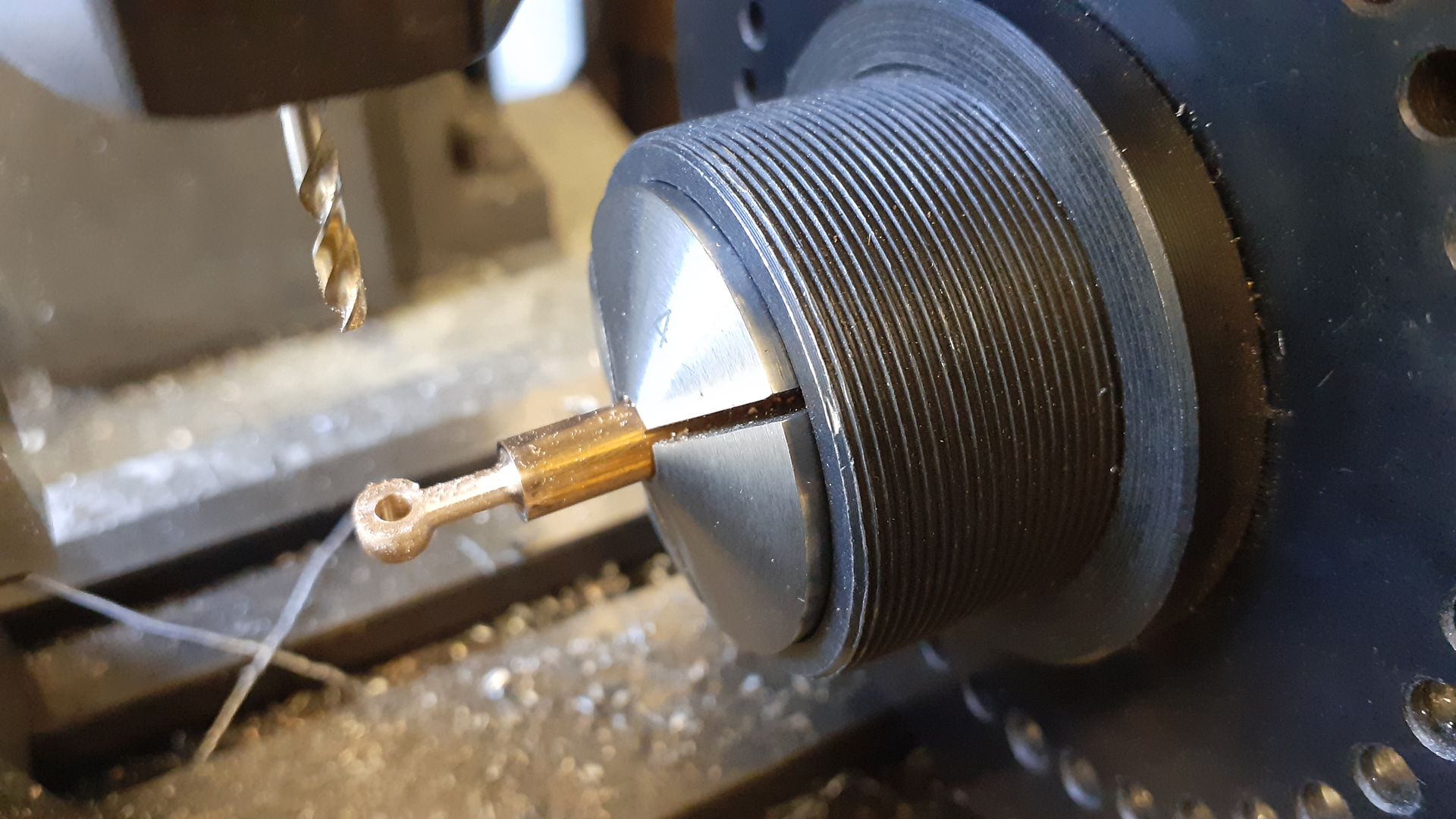

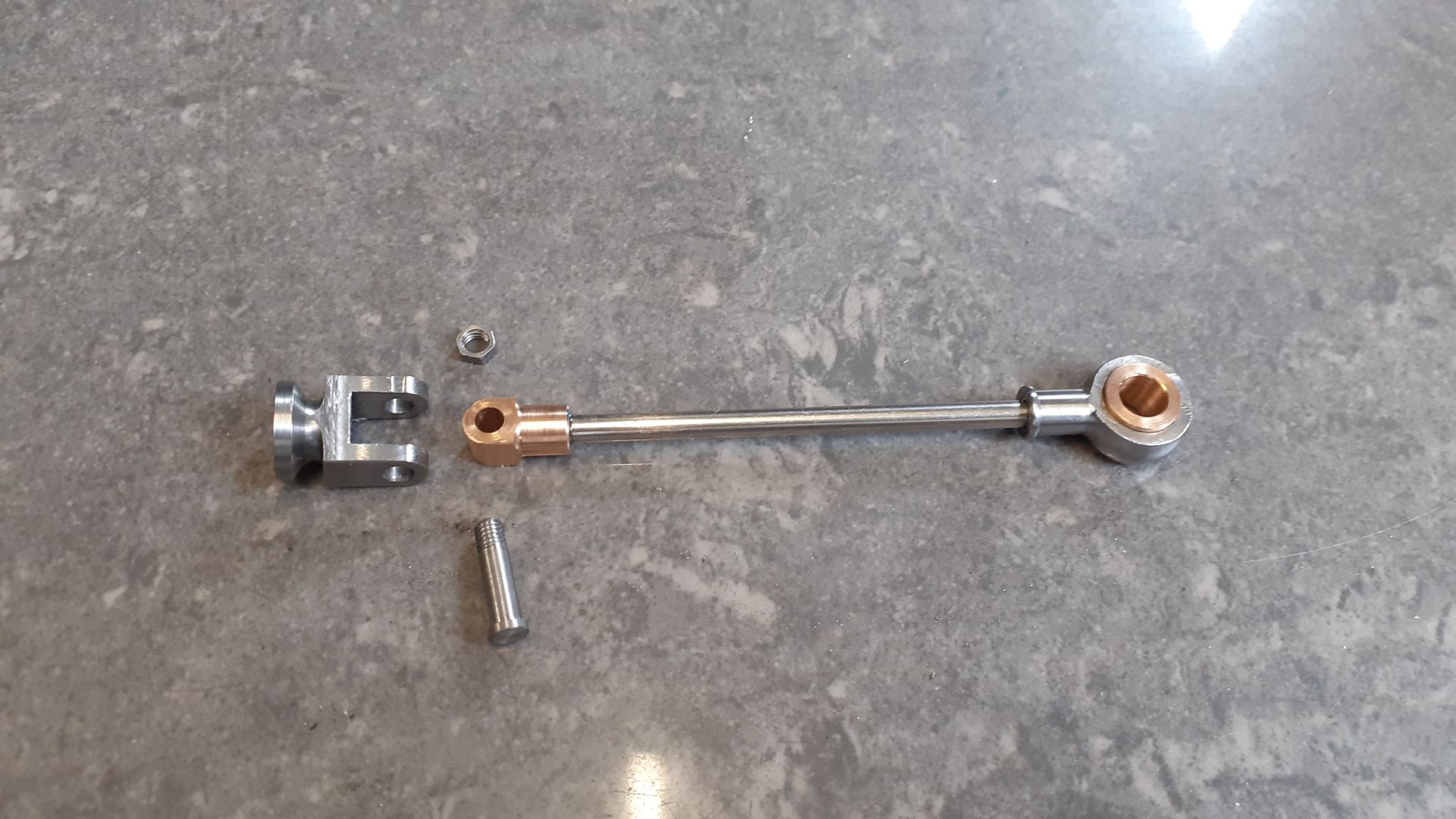

Bearings were simple turning and reaming from Colphos and loctited into place after which the oil hole was drilled through

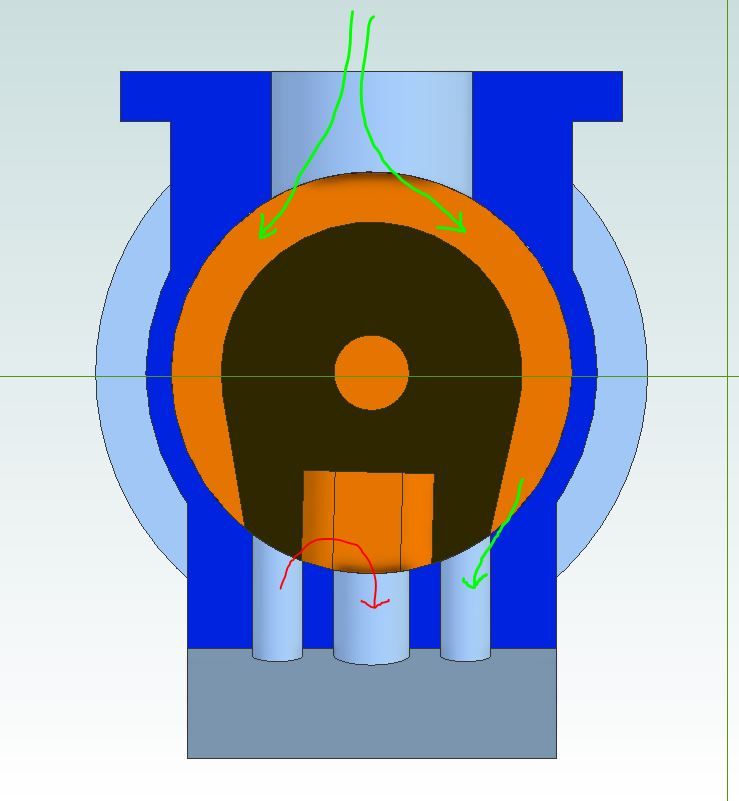

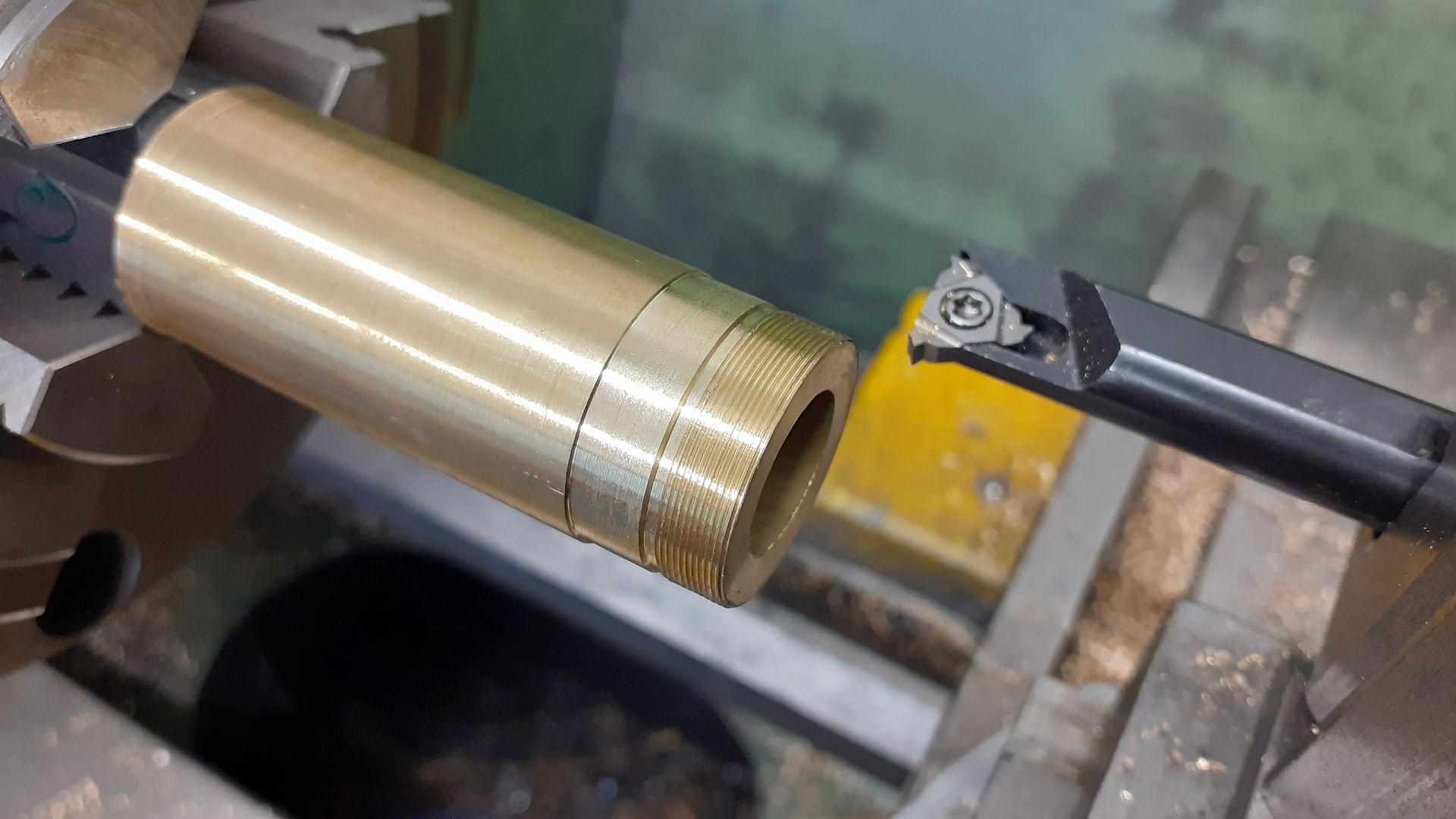

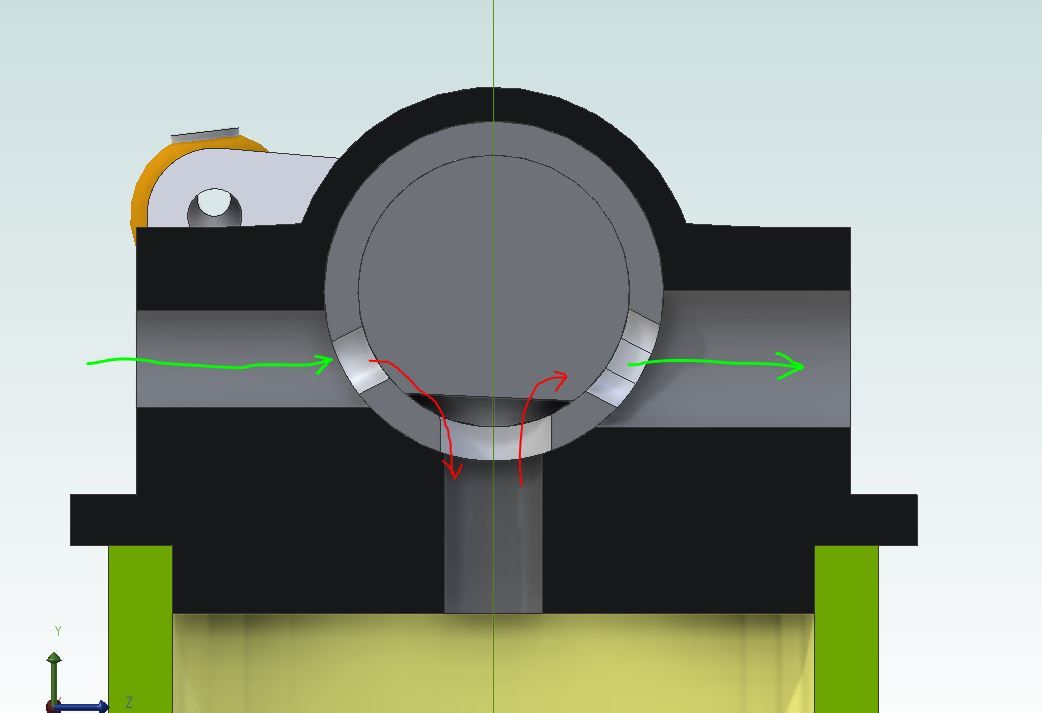

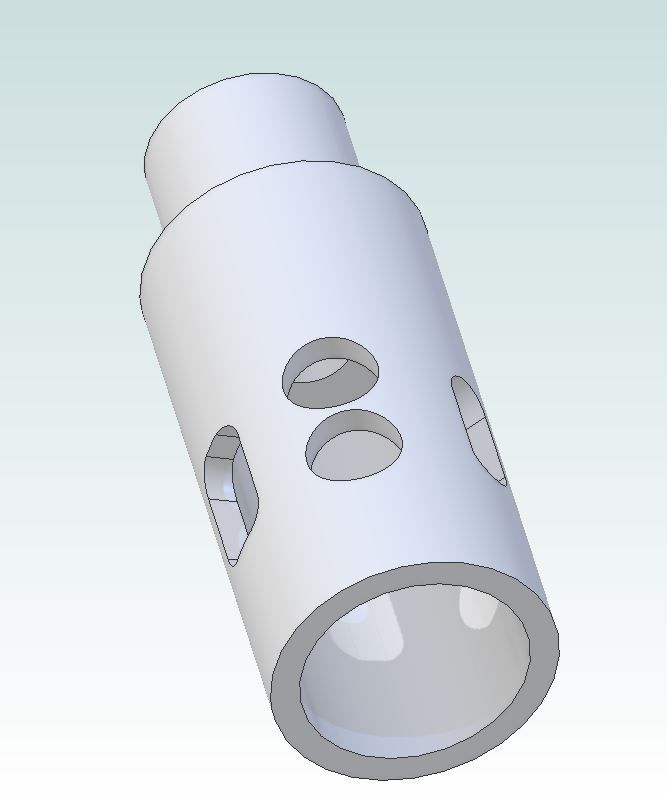

After turning the OD of the eccentric a 1mm parting insert was used to cut a central groove to retain the strap

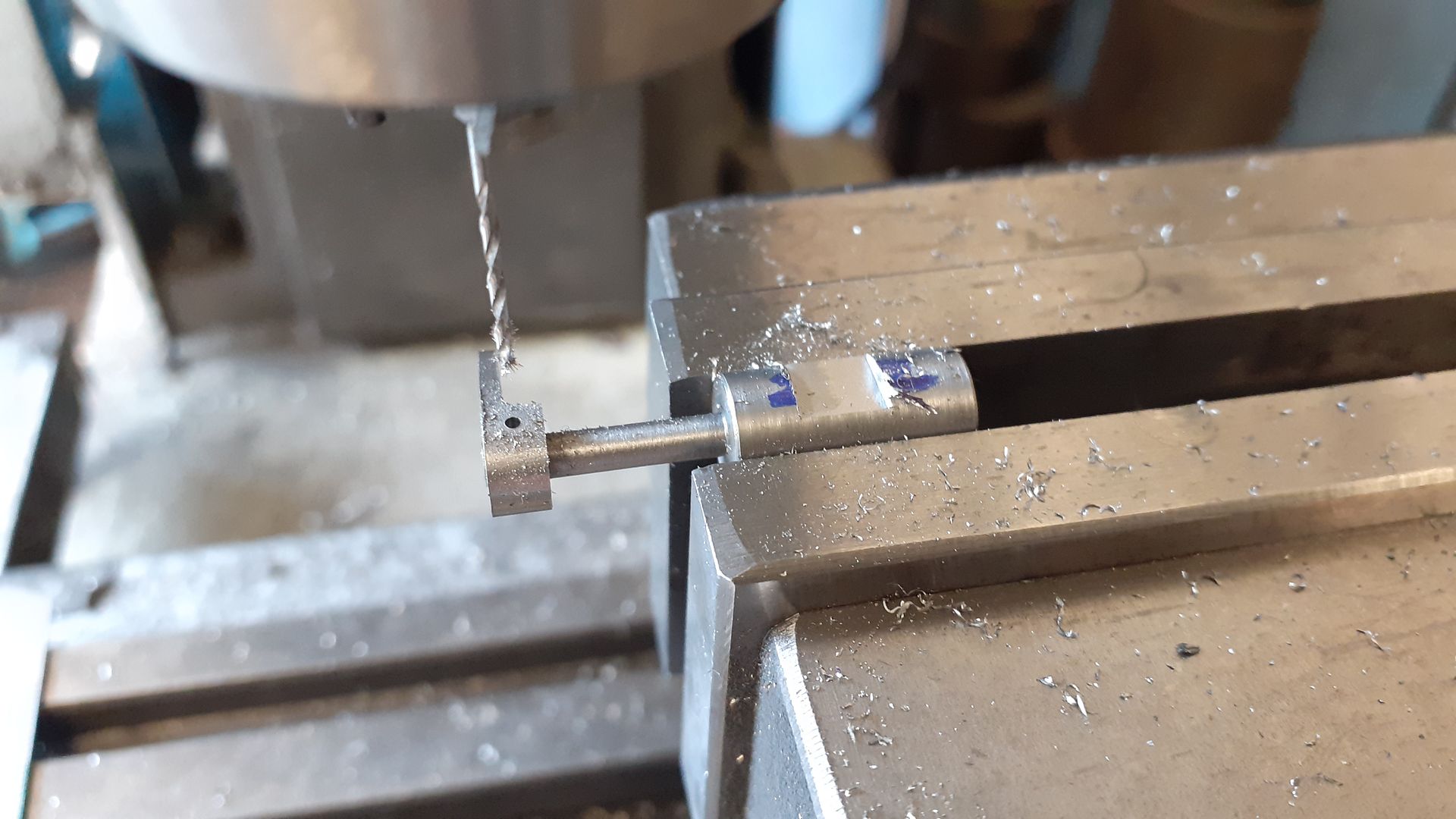

After which the stock was held in the small 4-jaw and clocked to give the desired throw before turning the spigot, spotting, drilling, reaming and then cut off

After tapping for a M3 grub screw the eccentric was mounted on a 6mm bar so the sawn face could be turned back to the final 5mm thickness

A piece of brass was square dup and then milled to 5mm thickness before boring to size using the eccentric to gauge the fit.

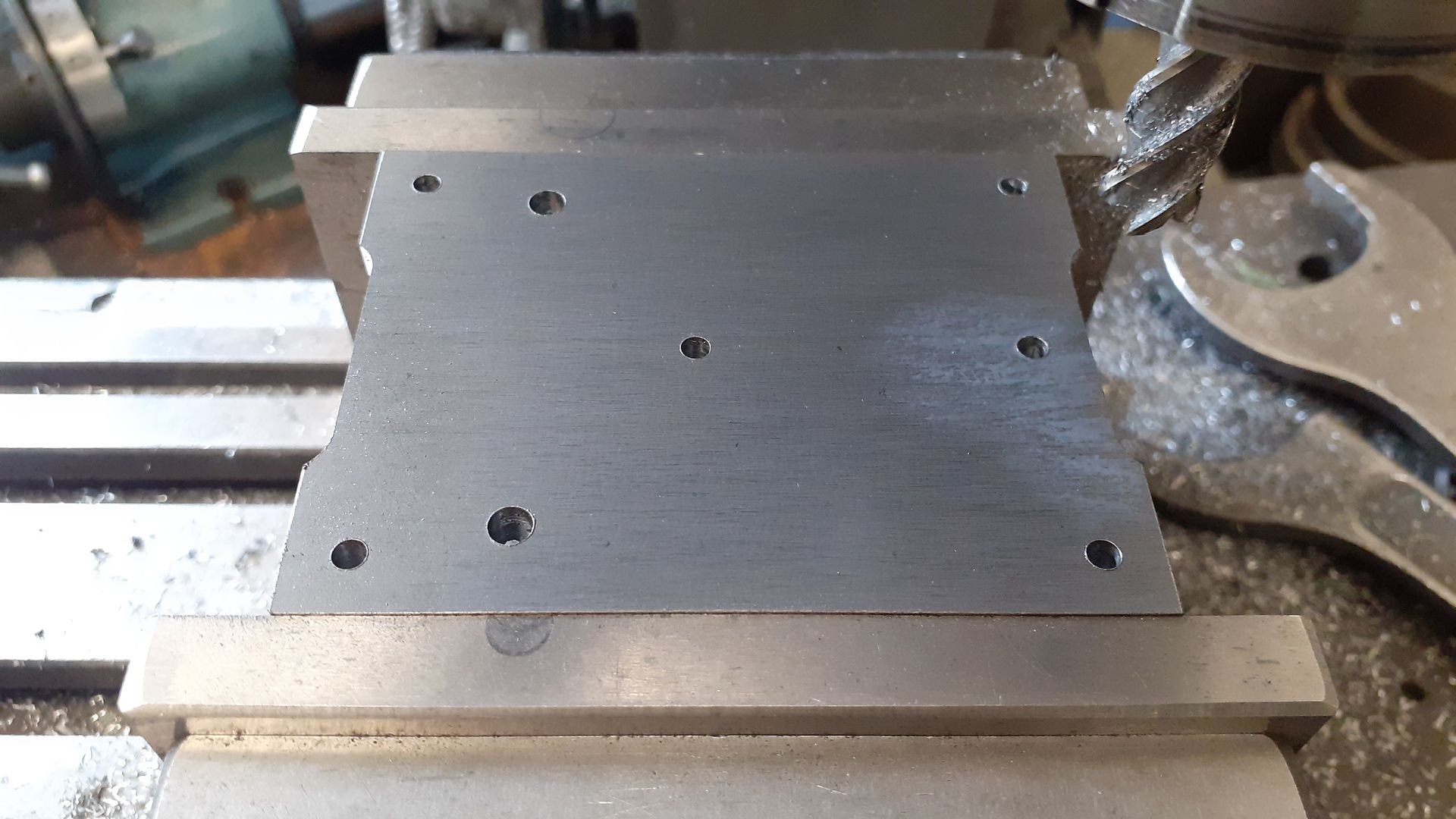

The outside profile was done on the CNC but could quite easily be done on a rotary table or even with filing buttons depending on what you have available.

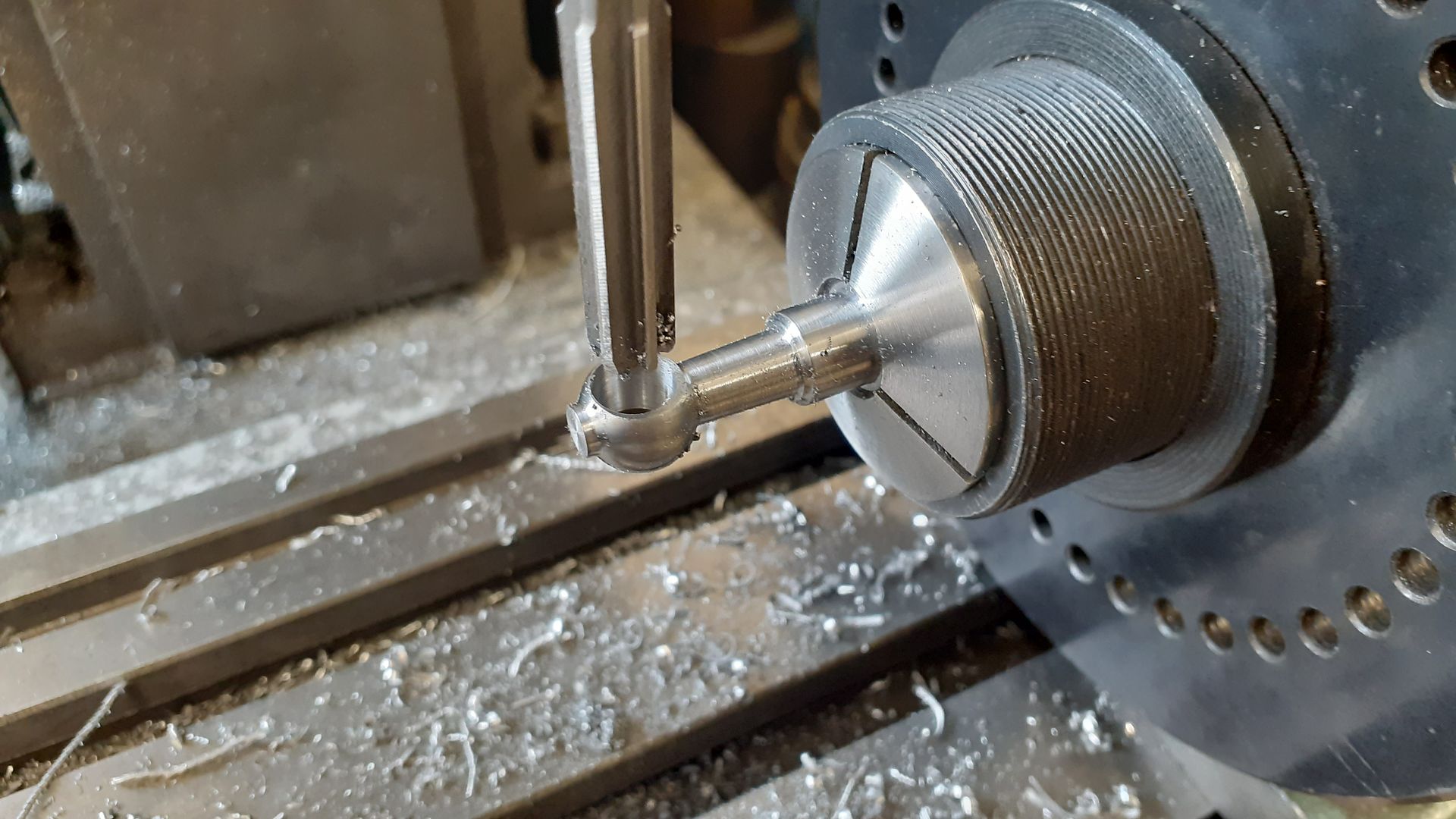

The eccentric rad was just 2mm dia steel threaded at both ends and the end that screws into the strap had a small spigot turned to locate in the groove of the eccentric

For the top end of the rod I kept the ball shaped theme going when making the rod eye.

DiogenesII.