It’s not the best iron, I would not want it for piston rings or a cylinder liner but OK for some things

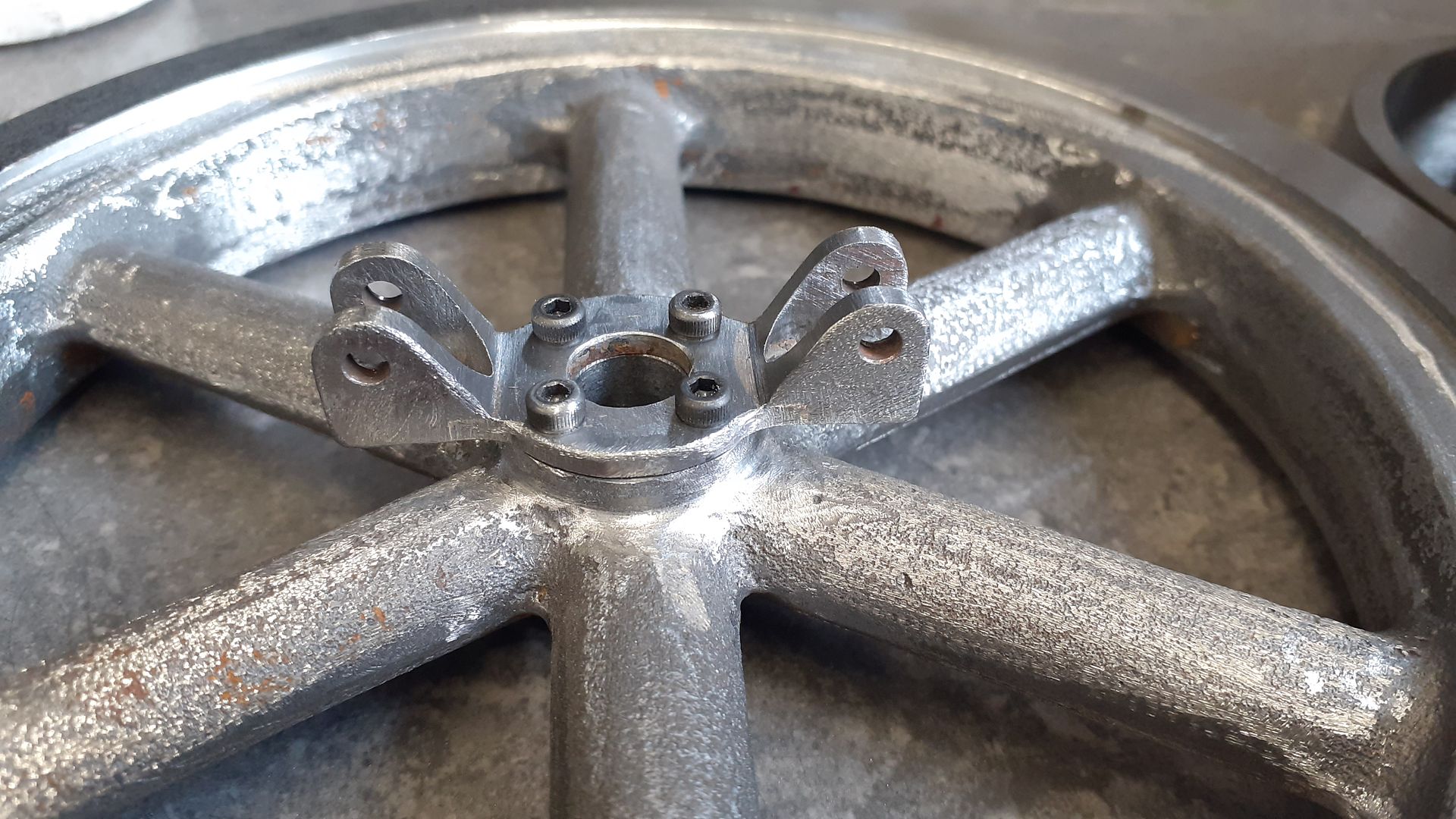

The two flywheels arrived at the beginning of the week, they did look a bit rough and had a fair amount of thin flash so the first thing I did was to take a small cross pein hammer and carefully chip the flash off. This shows the one on the right after chipping and the left as delivered.

I then fettled the flywheel, I like to do this before any machining a sit saves marking the finish turned rim if you intend to leave that bright. It was mostly done with files and then a quick tickle with the Dremel equipped with a grinding bit, again one on the right has been fettled. There is a little more to do between the spokes where they meet the hub.

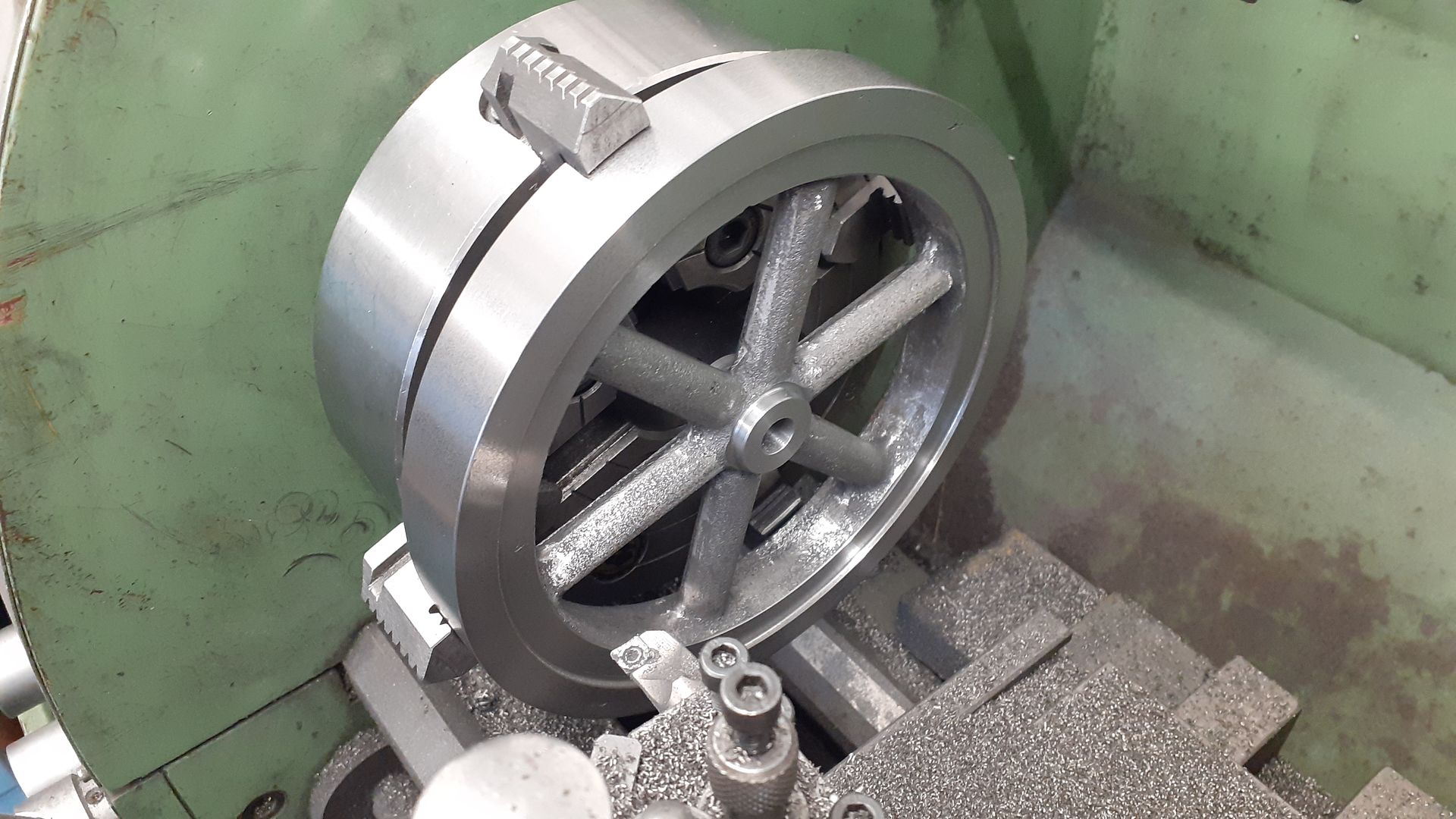

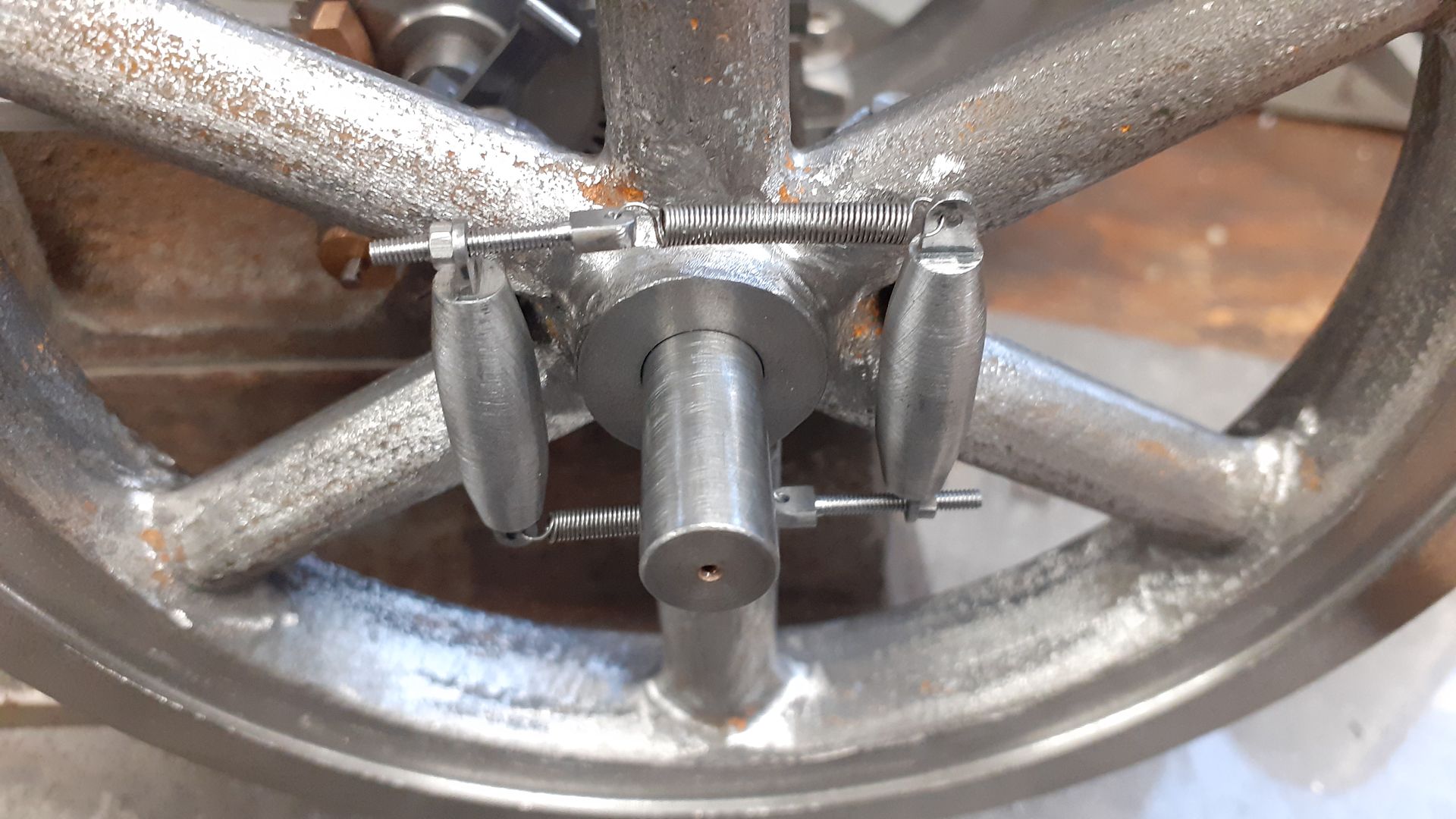

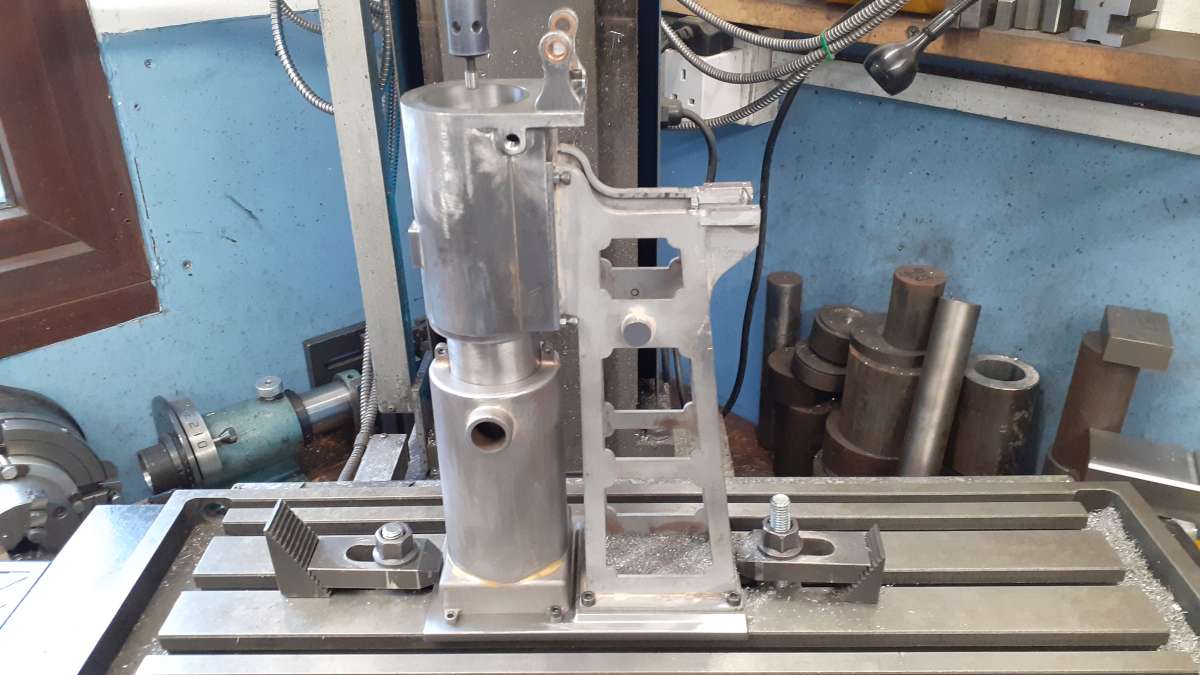

Where possible I like to hold flywheels by the inside face of the rim and get that to run true as it is not a surface that is going to be machined, this is another reason to clean them up first. With the 3-jaw’s jaws reversed it fitted easily and was just tapped on the side until it ran with minimal wobble.

My machining sequence was:

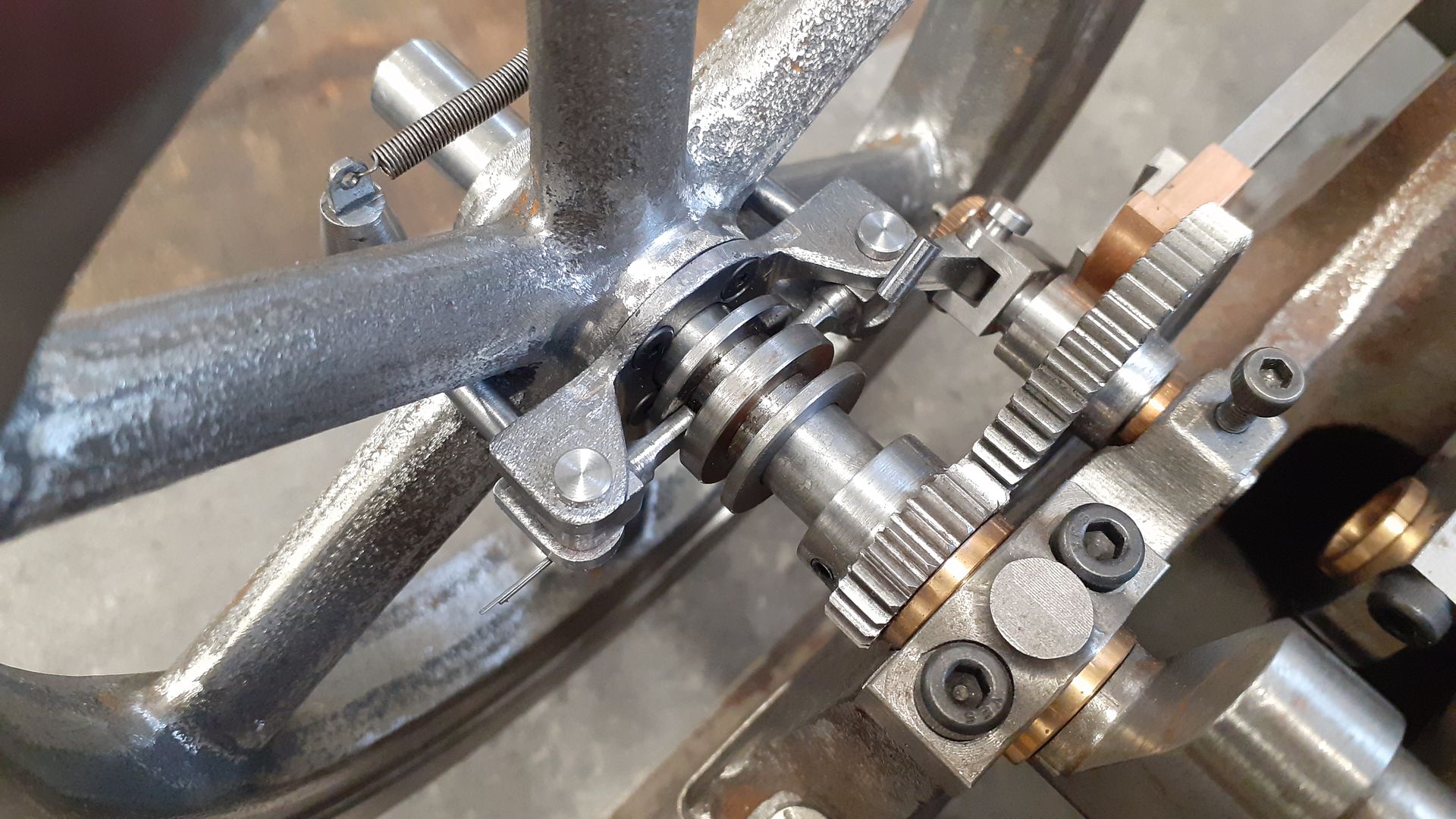

Rim OD, Rim Side both these done with CCGT inserts using the holders that make use of the two “spare” corners.

I then changed to a boring bar with 0.8mm corner radius CCGT insert and flattened off the side of the inner rim, this ended up 1.75mm below the side face of the rim.

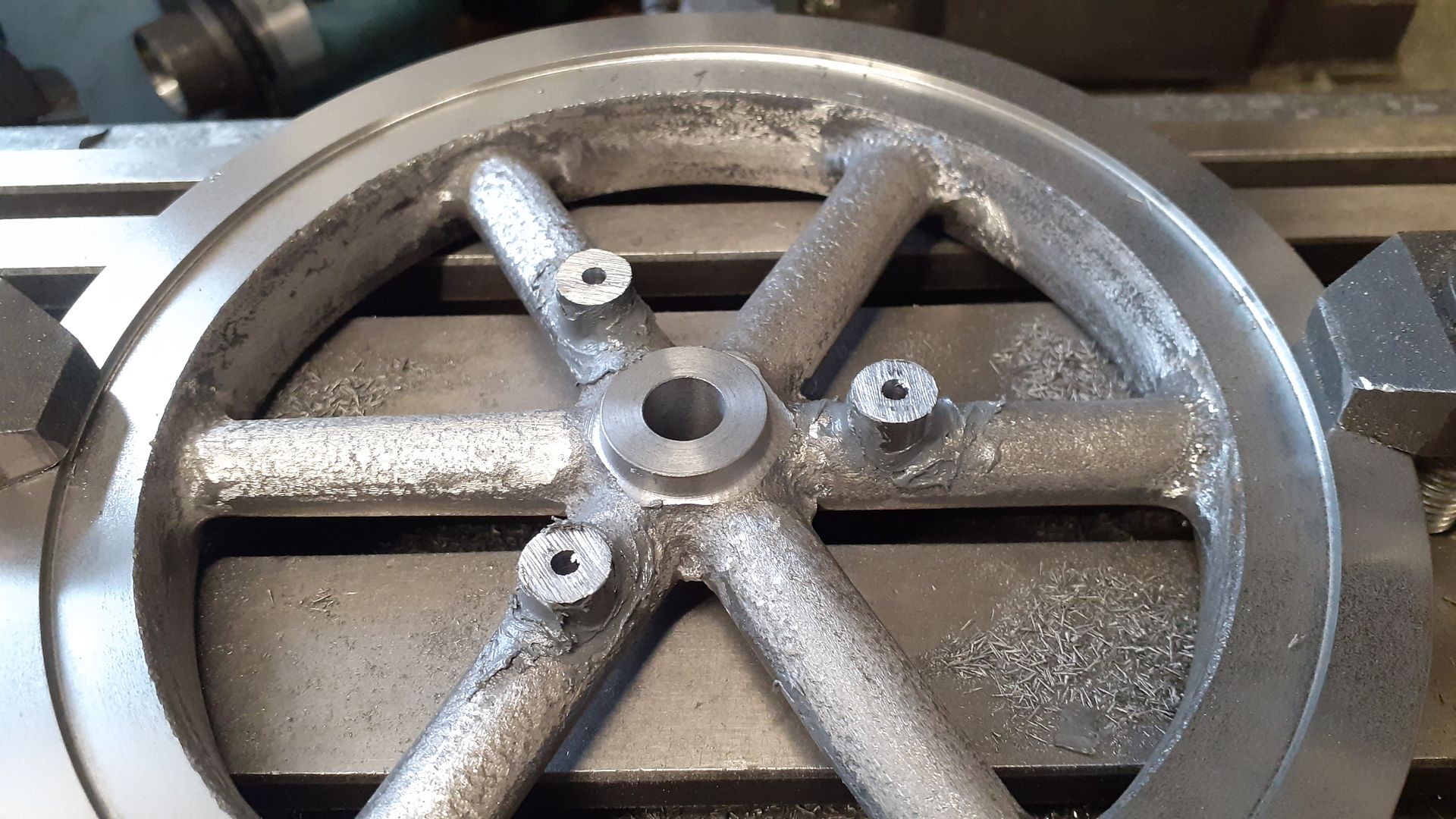

The hub was then faced, spot drilled, drilled 6mm with a stub length drill, opened out to 9mm and then a boring bar used to take it out to final 10mm dia using the crankshaft material as a plug gauge to get the fit right which is tighter than a nominal 10mm reamer gives.

Lastly change to a brazed tip tool with 1.5mm nose radius, set the topslide to a few degrees and clean up the OD of the hub. Knock off all corners with Lathe file.

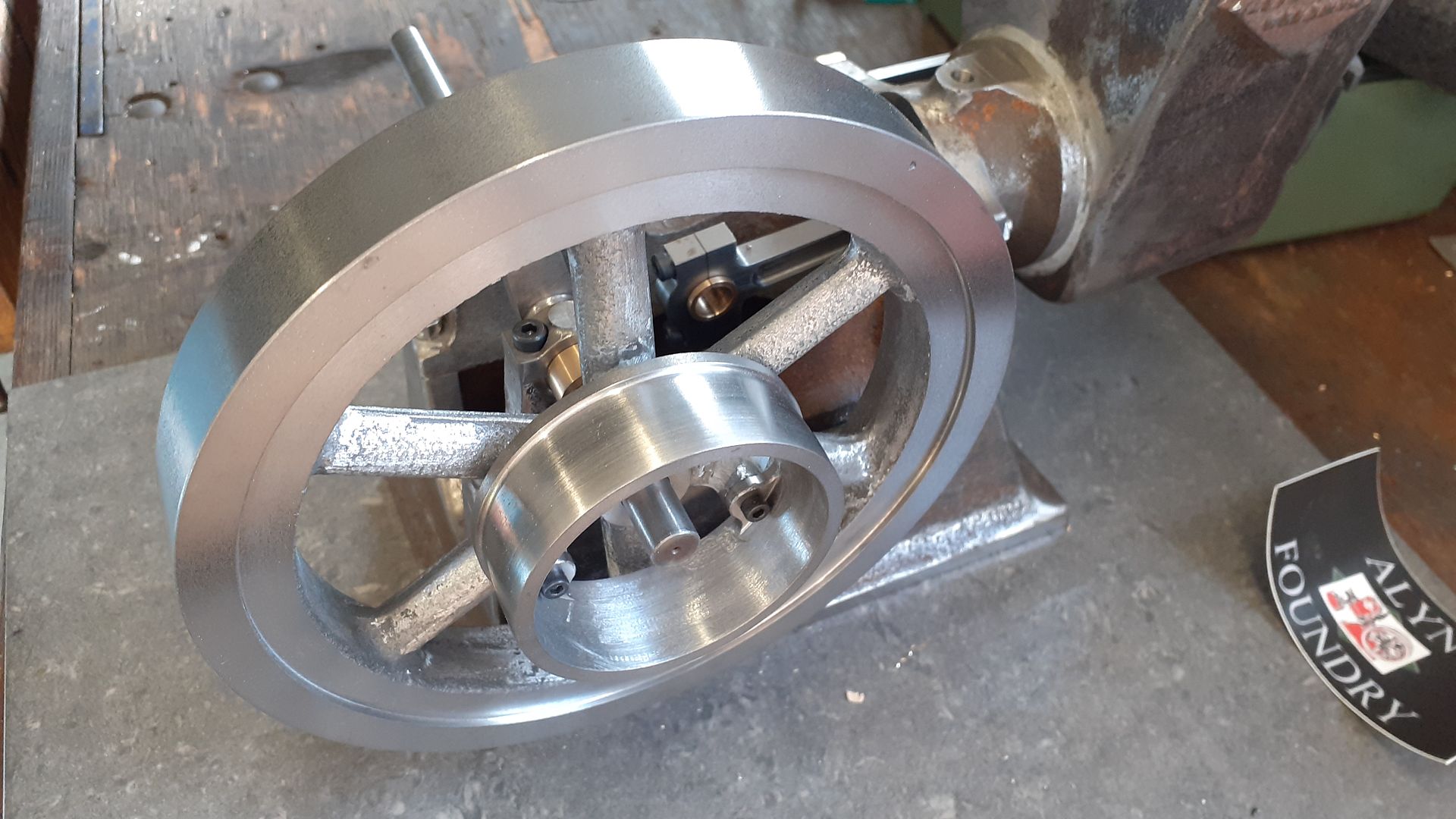

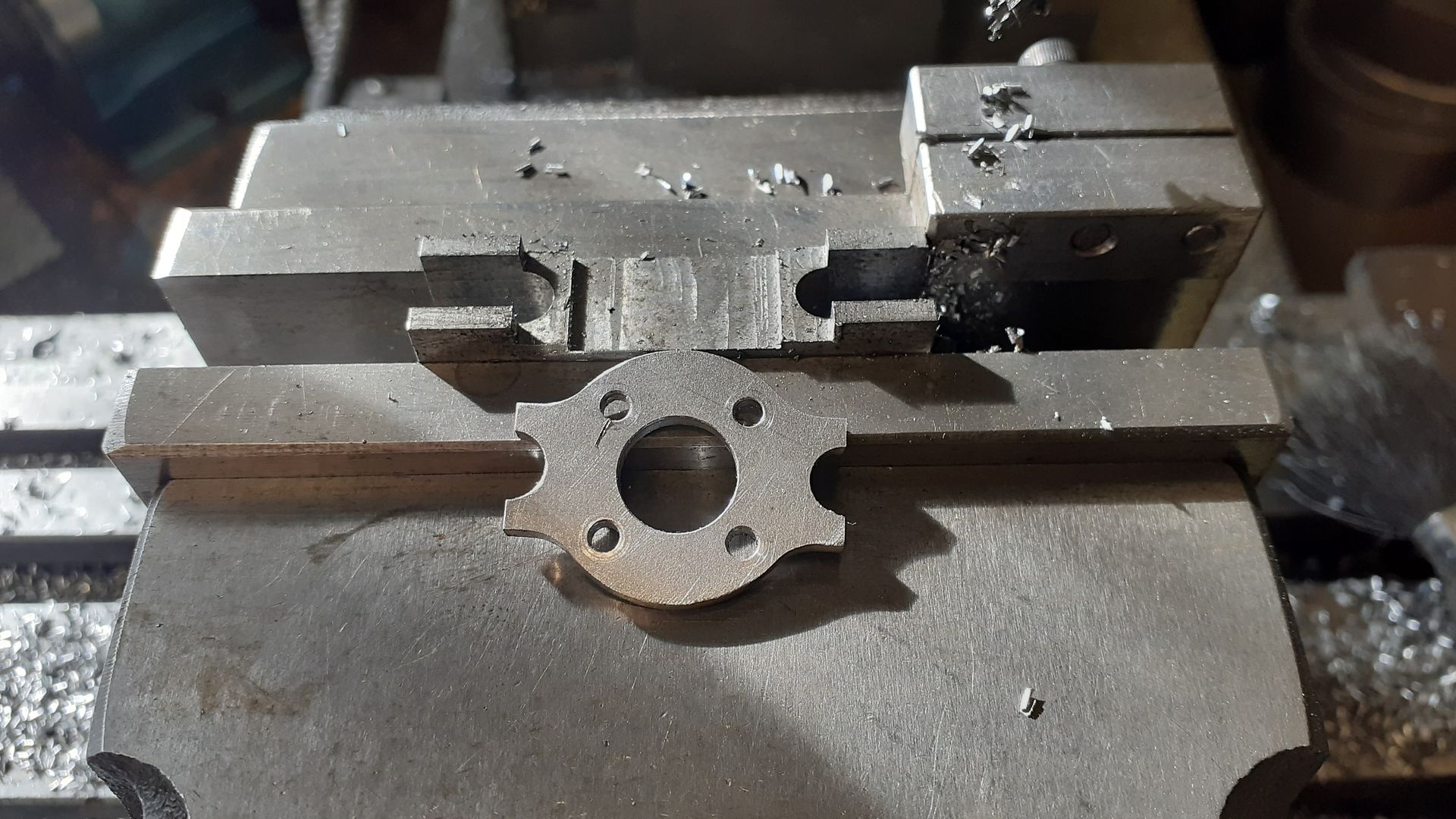

To do the other side I changed to the 4-jaw and got the flywheel OD running true before machining Rim side, recessed side, hub face, hub OD.

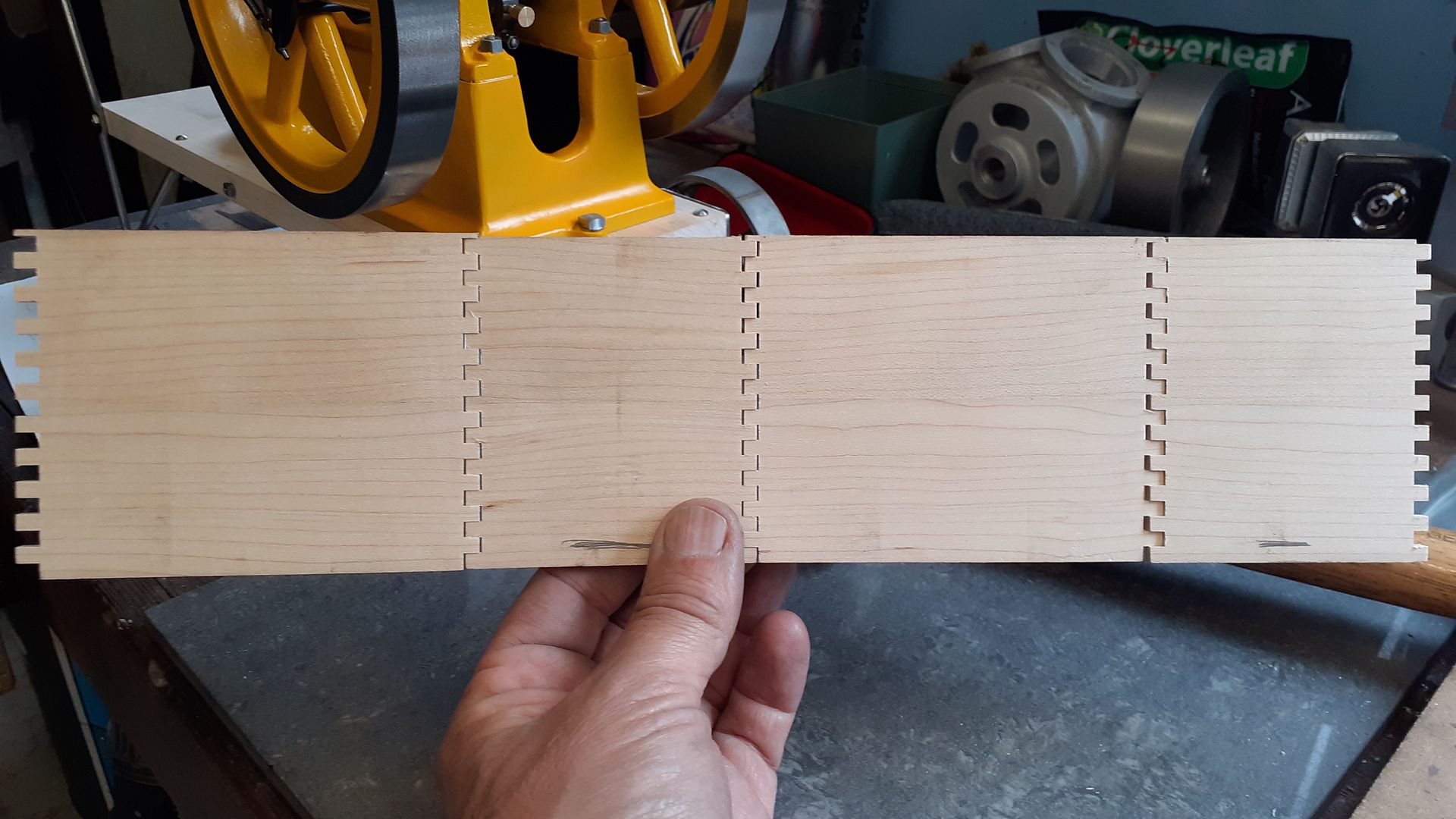

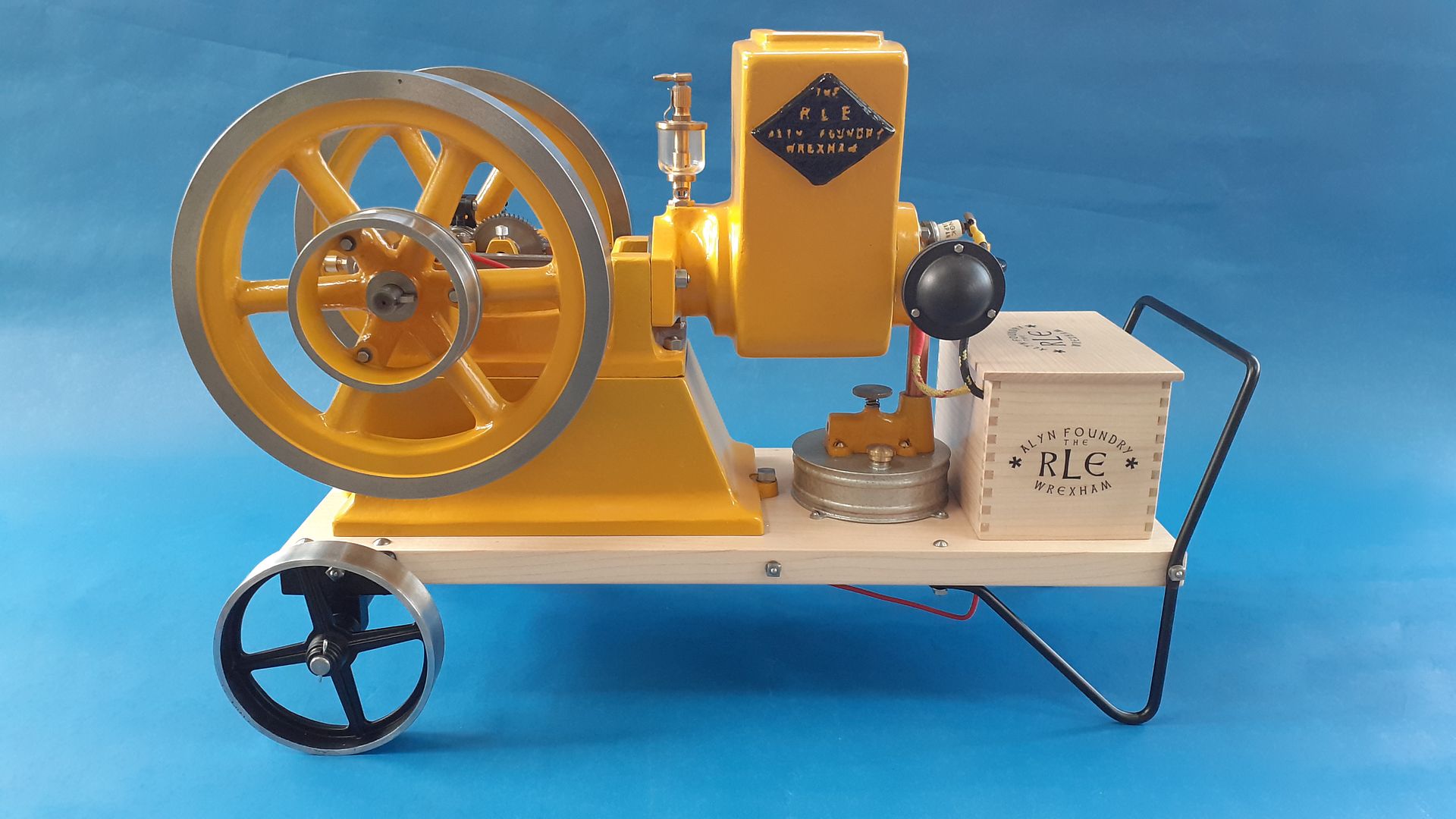

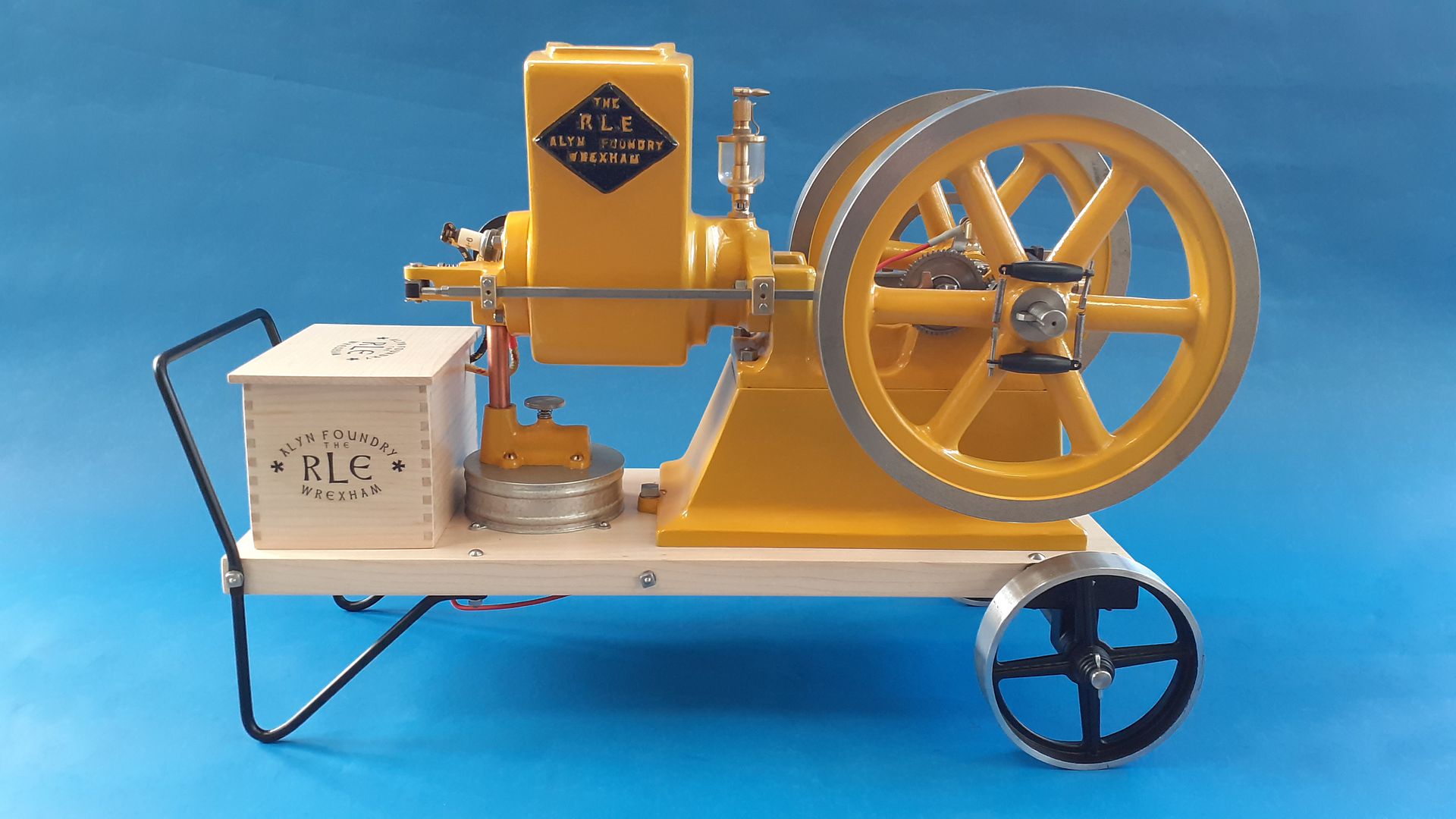

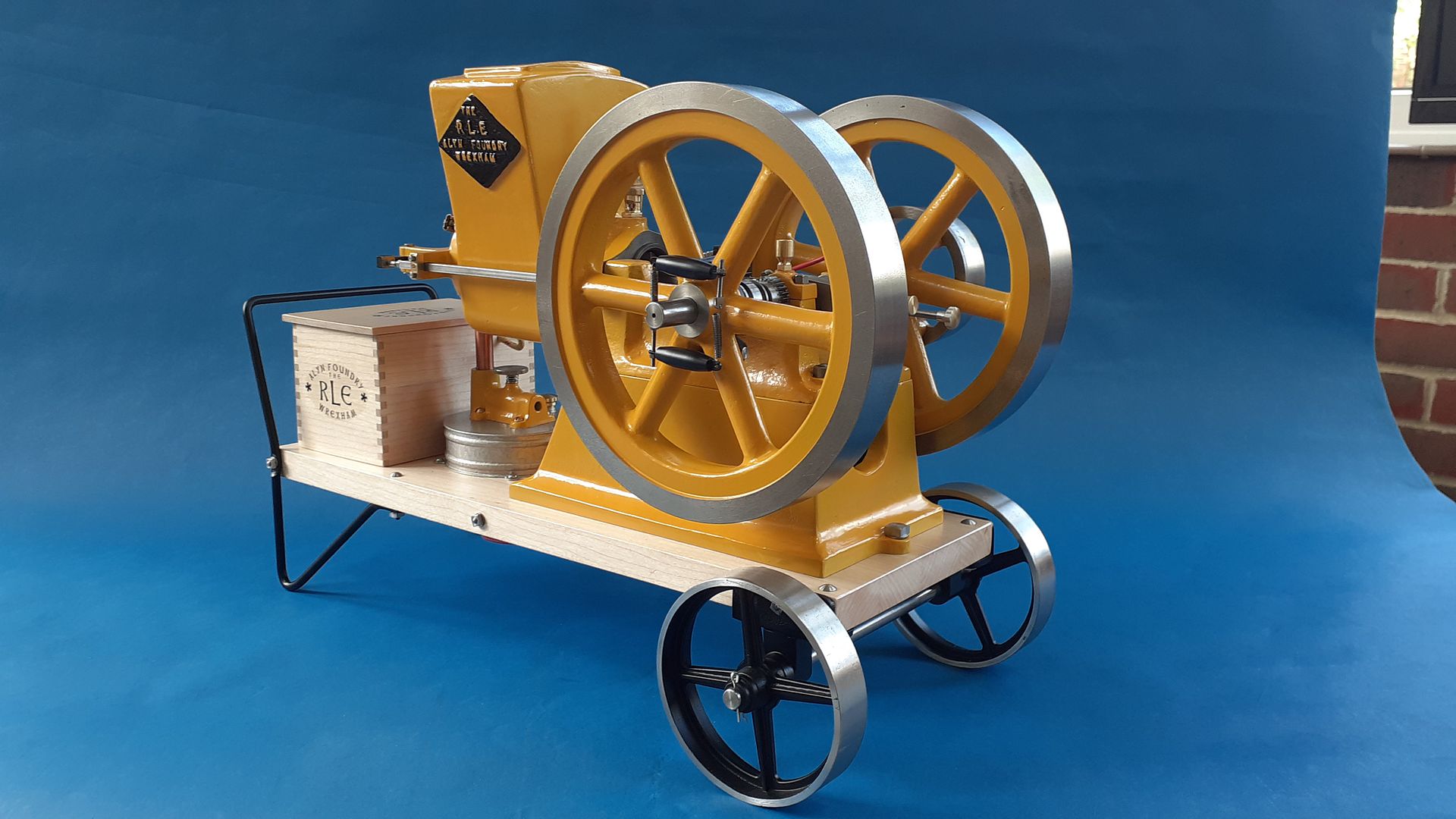

With two done it was time for a trial fit

derek hall 1.

![20230802_162555[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/u2fju7cacngg2fbnyra856s6rpoe2zba.jpg)

![20230806_083159[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/idsblm8qfbt1retjaip7m1vl5jgtf2nj.jpg)

![20230806_083541[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/gk5325ycbo2zkr08cb33skuoyhngn6zf.jpg)

![20230806_085914[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/taf4m8892vfhy7k34pembp3ph3m2ba4y.jpg)

![20230806_092255[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/mcheud7weqk26sq0ef590dv6x6zqwvrg.jpg)

![20230806_122235[1]](https://www.model-engineer.co.uk/wp-content/uploads/sites/4/hm_bbpui/701139/ci8t7xp9c0w27izwjb1lctinmyjtco9s.jpg)