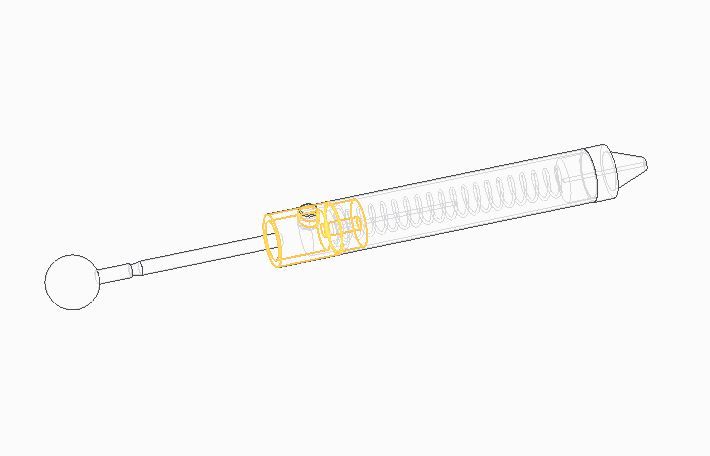

Self-training in Solid-edge led me to model a Solder Sucker:

Although my focus is learning CAD, I'm also keeping an eye on the possibility of making a real one.

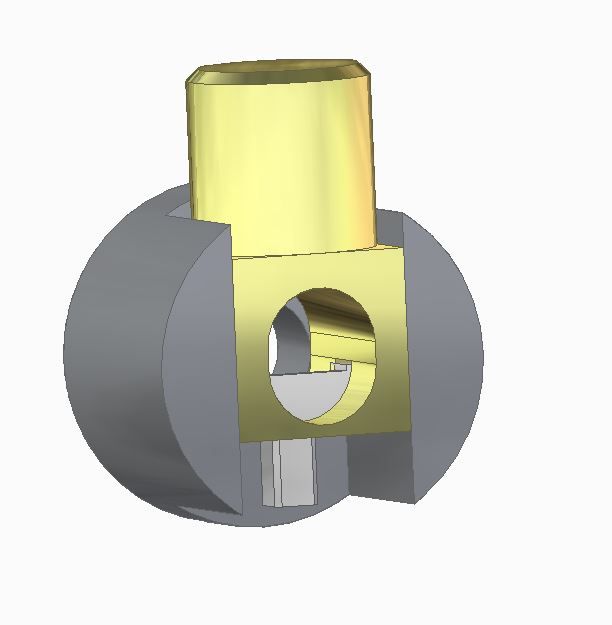

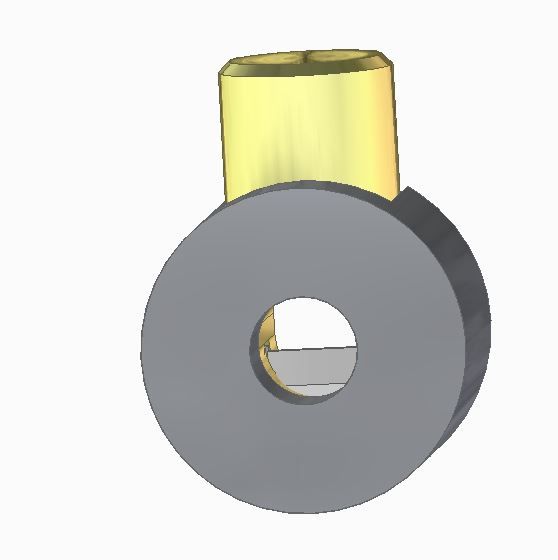

The 5mm diameter rod and thumb-piece on the left compress a piston against a coil spring until a notch in the rod engages with some sort of trigger under the button. When the button is pressed, the sear releases and the piston whizzes back creating a vacuum into which any molten solder under the nozzle flies.

The rod is stopped from ejecting out of the tool by a circlip. Interesting design point: it doesn't smack straight into metal – it's cushioned by a washer and foam pad.

Happy with the circlip except it needs a 0.6mm wide square edged slot to be cut into the rod's end. As cutting a slot that narrow for a small circlip is a bit tricky, I wondered about other ways of securing the rod.

In the picture, circlip at top, Meccano methods below.

Sorry about the ghostly photo, but from left to right: a flexible rubber collar that grips the rod firmly; a steel U-clip; and a brass collar with set-screw.

I think the Meccano methods are all unsuitable for a retaining a rod propelled by a coil spring. Can anyone suggest another way of keeping the rod in place?

Ta,

Dave

Edited By SillyOldDuffer on 26/04/2022 15:03:49

Nigel Graham 2.

![20220426_223108[1].jpg 20220426_223108[1].jpg](/wp-content/uploads/sites/4/images/member_albums/185295/907152.jpg)

![20220426_223033[1].jpg 20220426_223033[1].jpg](/wp-content/uploads/sites/4/images/member_albums/185295/907151.jpg)