Posted by Lex Davis on 29/08/2023 08:17:19:

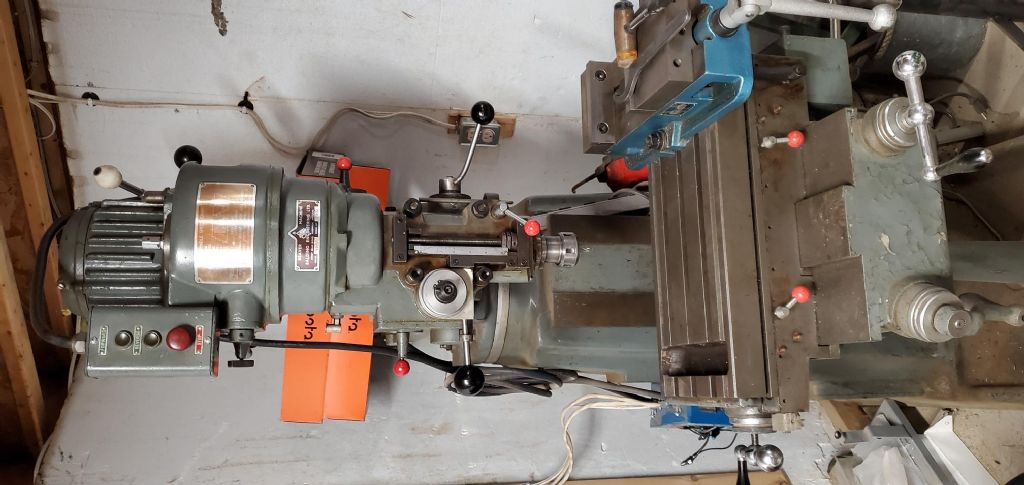

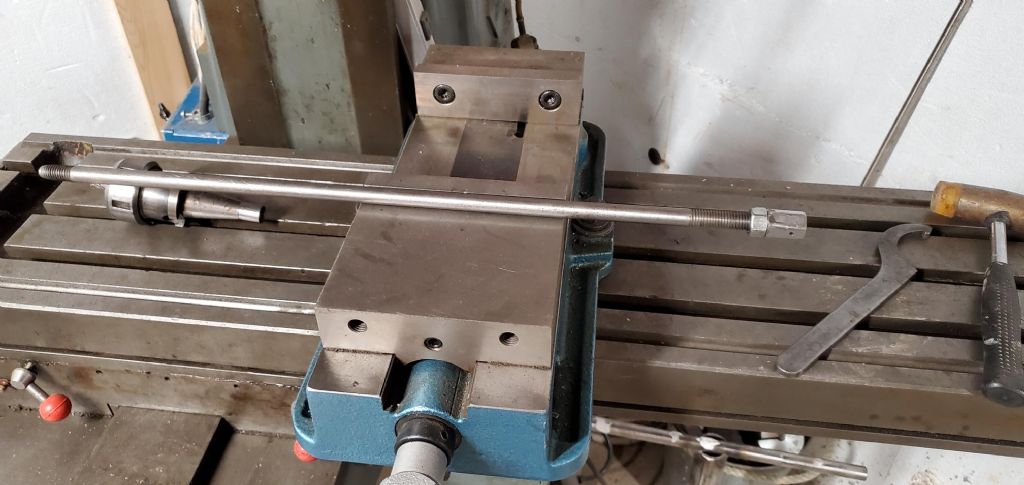

My VBRP – 2 seems to have a lot of oil passing down through the spindle from the back gear housing, the diagrams in the parts manual are not very clear as to the sealing arrangement in there, has any one resealed one of these machines?

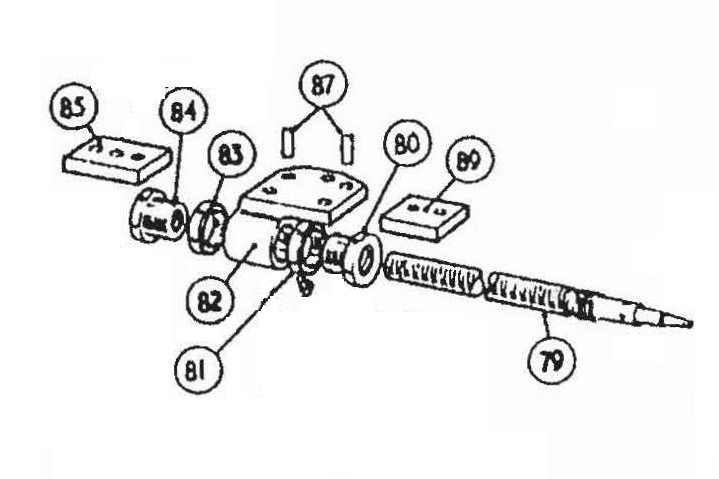

Lex, I did a clearer traced diagram of their exploded diagram of that area :

https://www.model-engineer.co.uk/wp-content/uploads/sites/4/images/member_albums/143475/808162.jpg

And of the casting alone :

https://www.model-engineer.co.uk/wp-content/uploads/sites/4/images/member_albums/143475/807977.jpg

In neither of them can I see any sign of an o-ring or flange seal, or any outlet other than the spindle/quill, but I'm unsure on orthogonal veiws. It looks like the only thing that stops spillage is the casting (green in dwg I think) being deeper than the back gear (dark blue in dwg), and the lower spindle seal (felt, hardens over the years, cracks apart when removed) leaks that spillage.

Obvious questions, but have you checked the oil sight guage on the front?. They are notorious for getting blocked with gunge and showing a fix incorrect reading. Over the years, the oil gets topped up and up and eventually over fill. Also, checked for casting cracks?

Maybe put a tin under the spindle, engage back gear and highest speed. Don something oil proof, stand well back, Quill up, push the startbutton, stop after 5 minutes, quill up, on for 5 minutes. Repeat. Or just pull the drain plug, change the sight guage, and refill.

scud106.