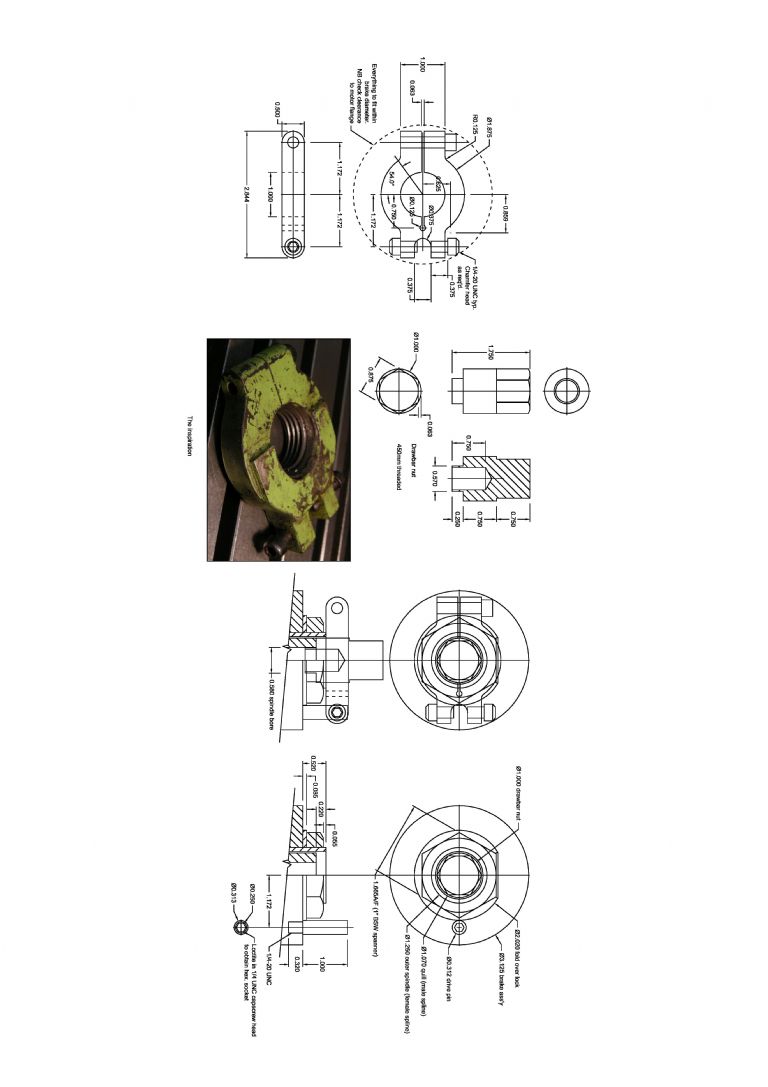

There was nothing between the bearing inner races of the driven pulley originally. A fitted spacer is probably an excelent idea to allow one to have a controlled pre-load while not needing surgical precision on the shifting spanner during tightening!

If the chattering noise occurs when there is no load, and no loose drawbar, then the pulley shaft and gear shaft probably arent lined up.

On the top aluminium cover there should be four cap head screws pulling the bearing carrier towards the cover and four allen grub screws pushing it away from the cover. You need to adjust these so that the dogs on the pulley shaft line up with the dogs on the gear shaft. The easiest way I've found is to start with all the screws loose, then gently nip up the grub screws until you get contact. Then gently nip up the capheead screws to take some straing. After that, with the mill running (and you probably standing on the table!) tweak the alignment by loosening/tightening adjacent caphead and grub screws to get the quietest running.

The dogs on mine are tapered, but I don't know if that was by design or has just happened over the last 60 odd years.The two sets of dogs do seem to match together without any play (unlike the spindle splines)

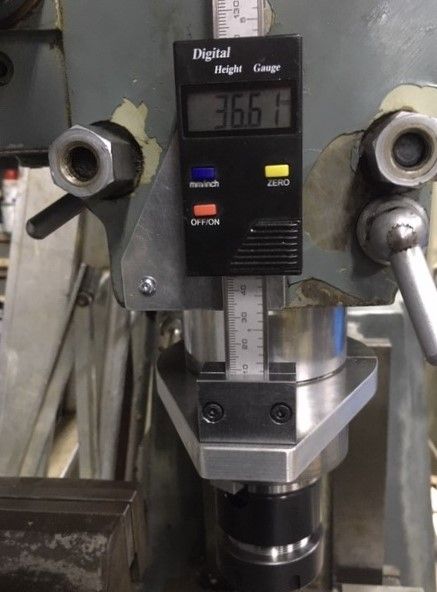

It should have a spindle lock, but they never designed one in to the Mk1… Simple way around this is a lightweight spanner on the drawbar nut (aluminium ratchet socket wrench in my case) and a sharp rap with a bit of bar or a 1 lb hammer.

In the tightening direction, one or more sharp tugs on the wrench handle usually seems to do the job. Lower speed belt settings make the technique more effective, which is good, since you nromally want a tighter grip on larger cutters.

Charles Lamont.