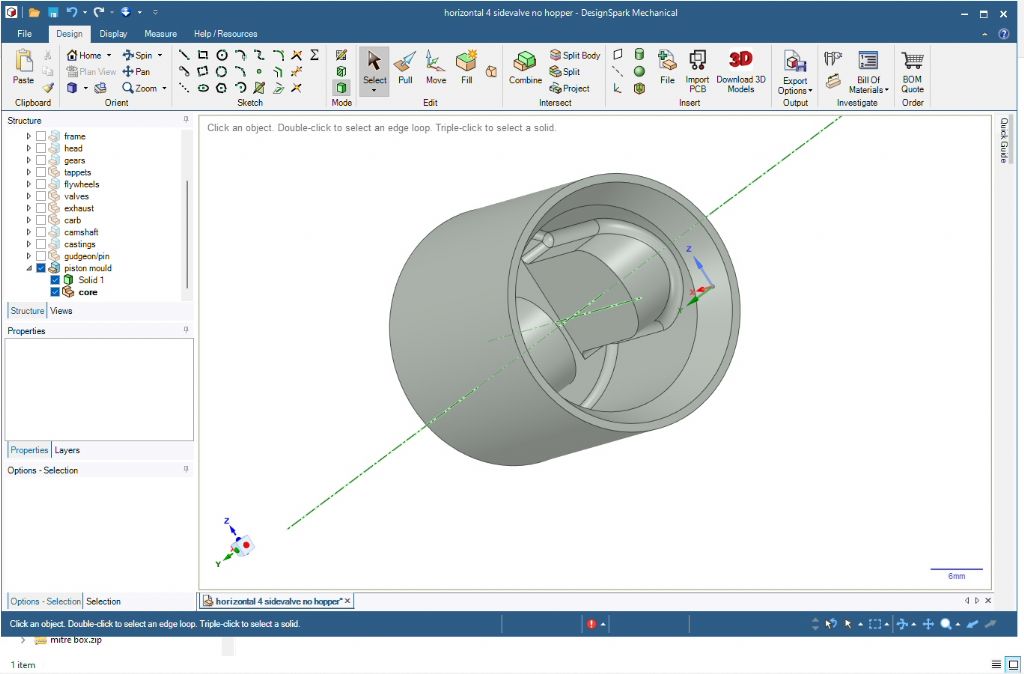

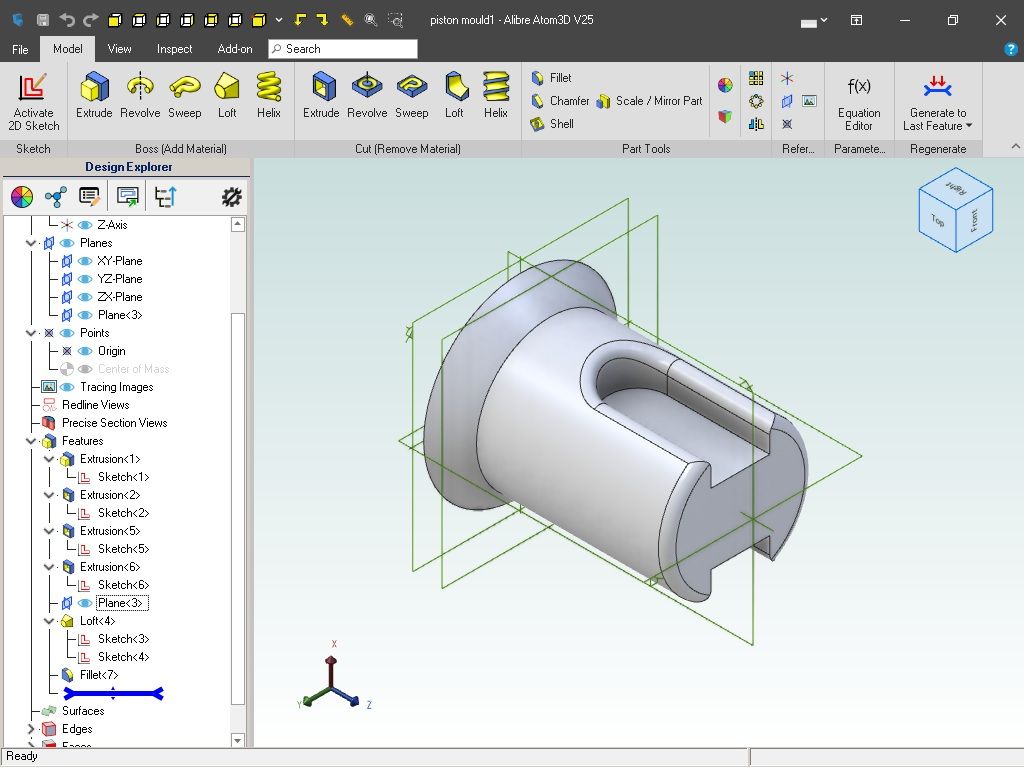

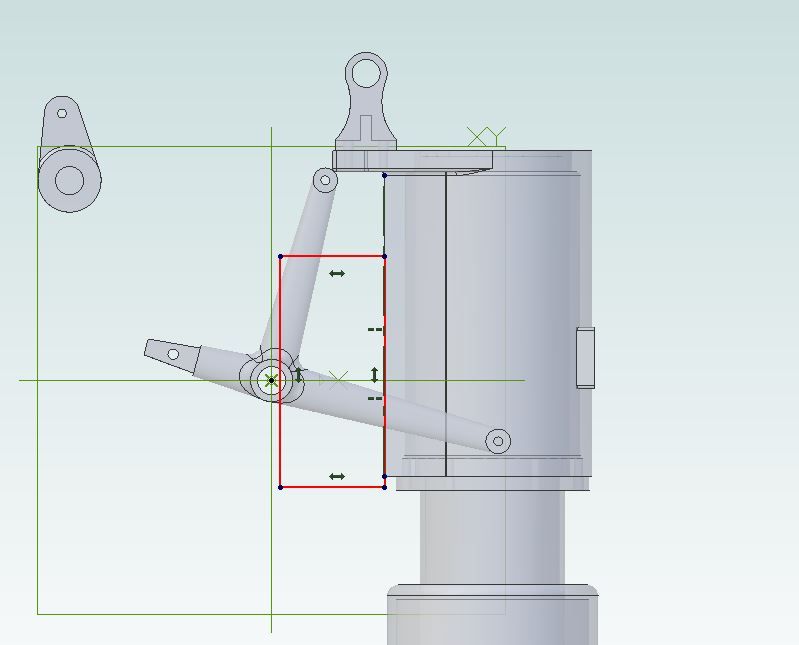

This is an example of my method of making a core box, or core mould.

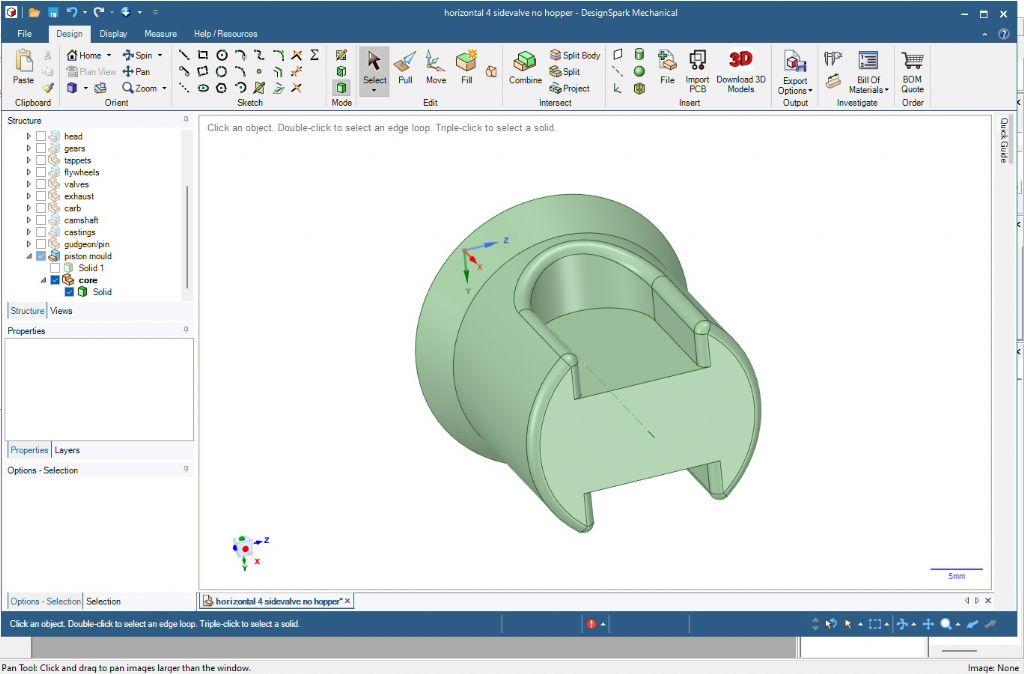

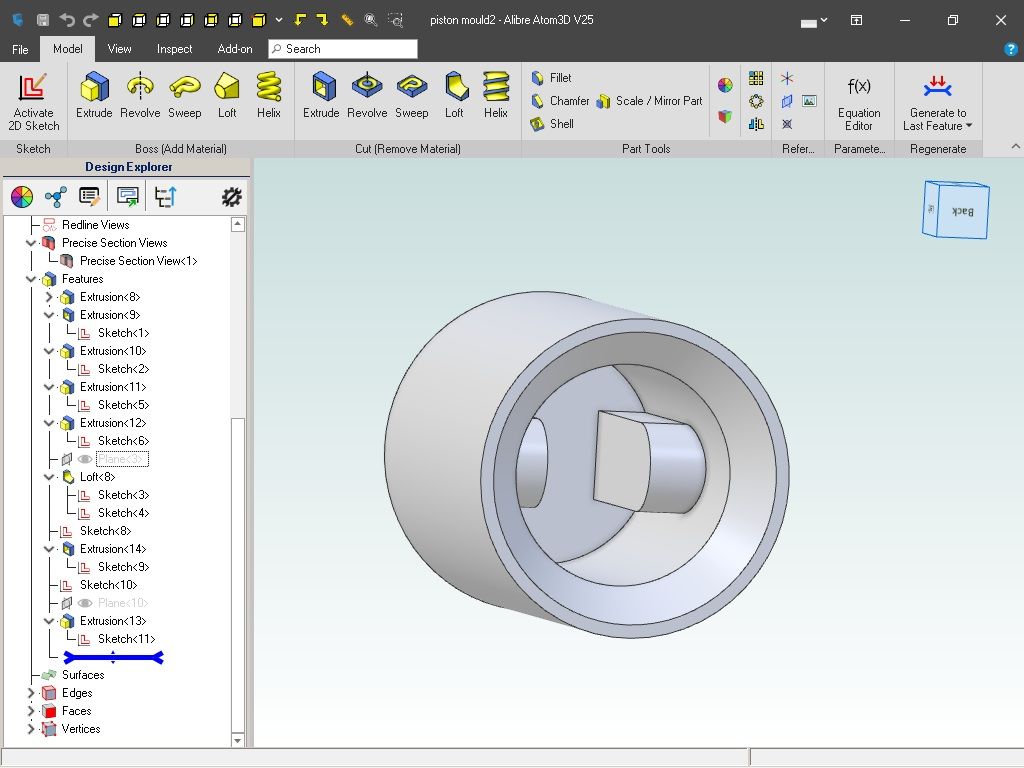

I want to make a core mould for this piston. The piston is grey because it is inactive.

I create a group called "piston mould" and in that group a body called "core". I select the end of the piston and start a new sketch. I use project to sketch to create a circle the dia of the inside of the piston, and then extrude that sketch to the other end of the piston to create a cylinder. I then cut the piston body from the cylinder to get the core. The piston body isn't destroyed! The chamfer isn't something I would cast in the piston, I would delete it from the piston body before cutting.

The core is green because it is the active body.

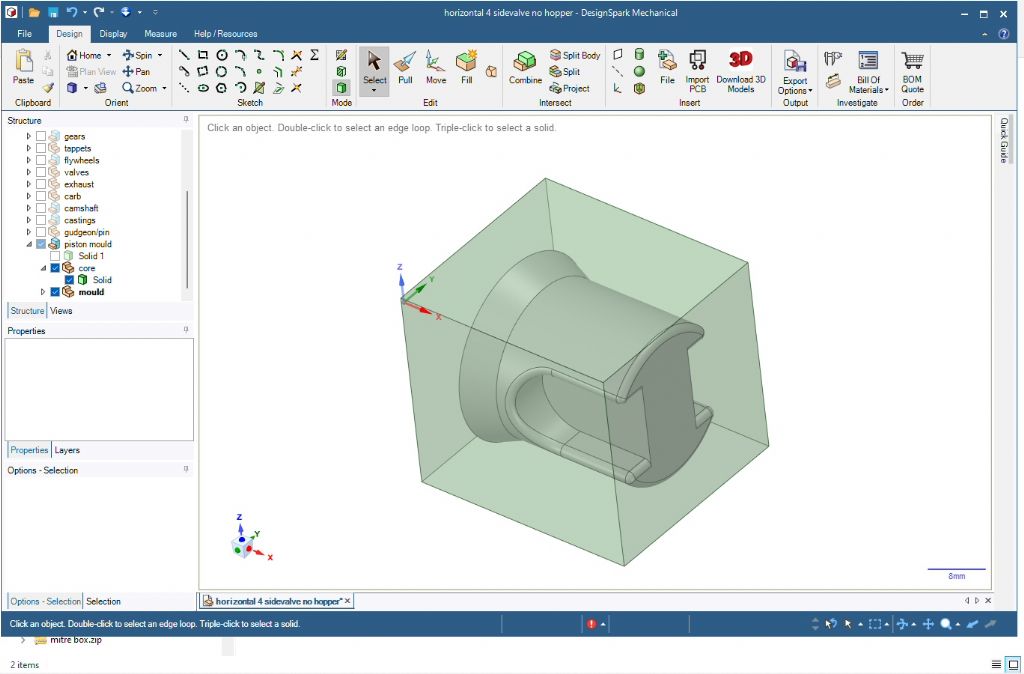

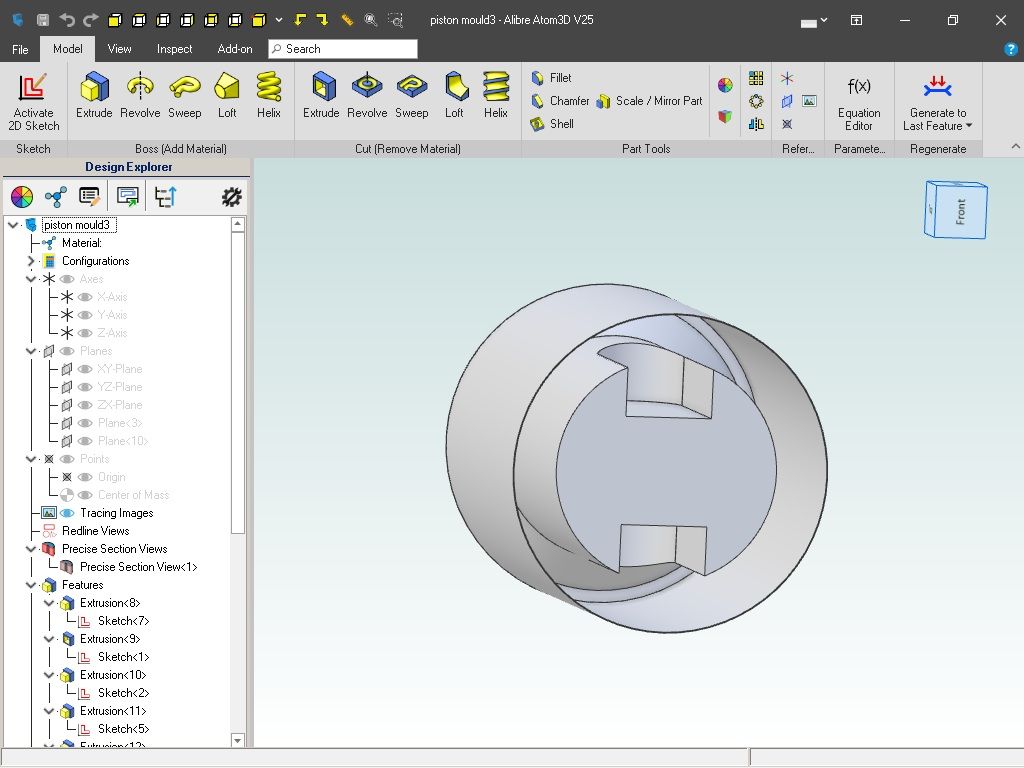

I then create another body called "mould". I've made it transparent to make the core visible.

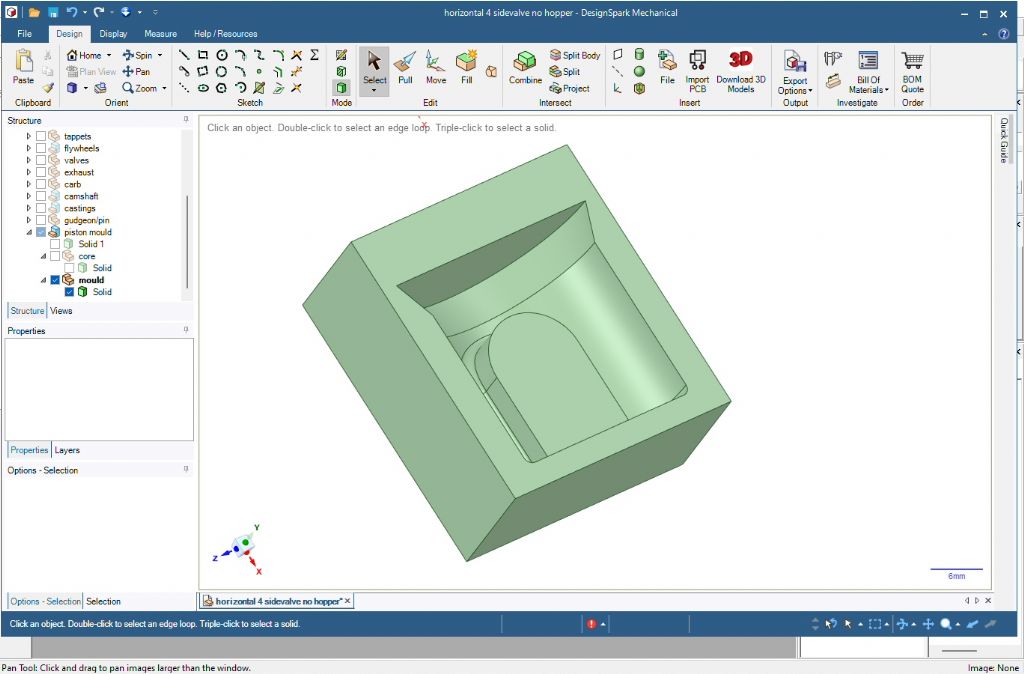

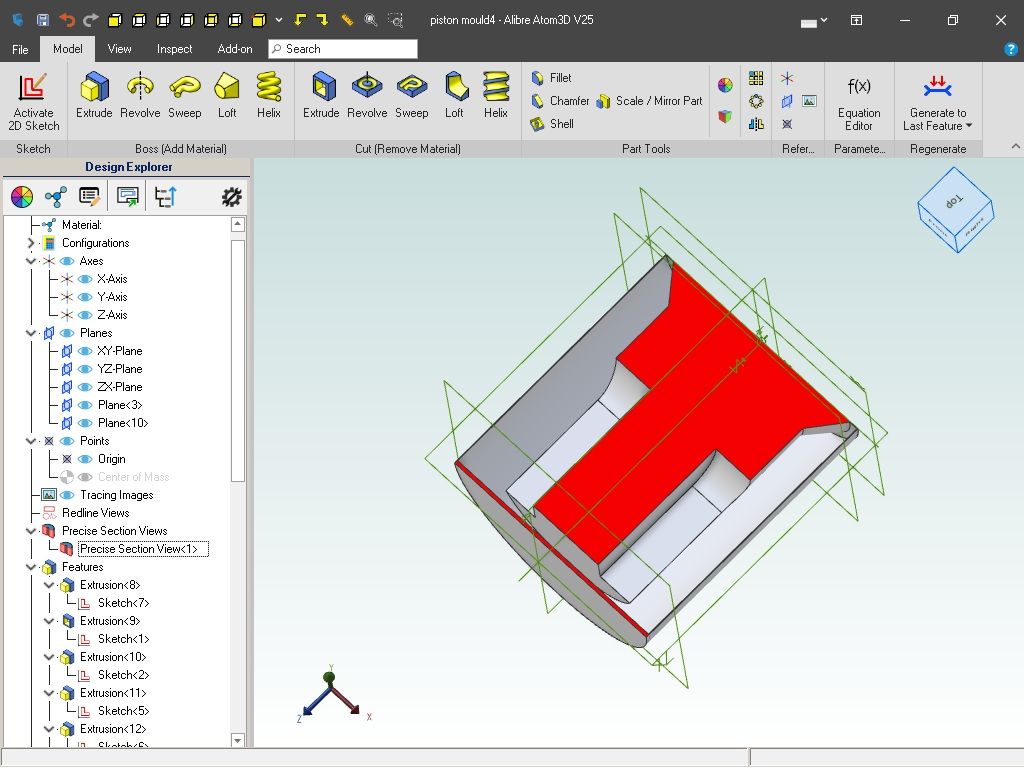

The core is then cut from the mould, and the mould split into two.

I can then add locating pins and flanges for bolts to the core mould and then use it to create a sand core.

I use this method to make most of my core moulds unless they are very simple.

The above process took about 5 minutes.

lee webster.