David –

Thank you clarifying that.

.

Martin –

What would help? Goodness knows. I don't.

'

Jason –

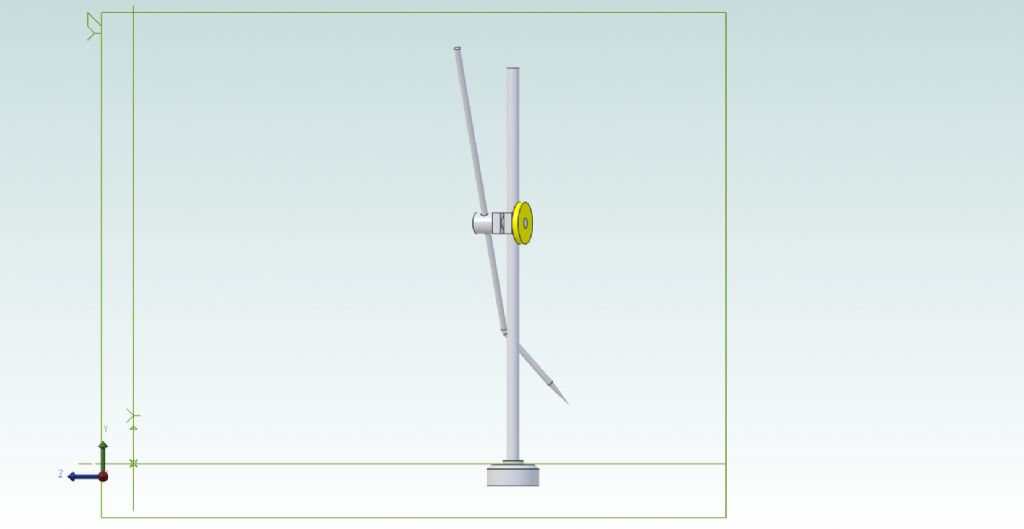

Got there eventually but what an exhausting, disheartening process (Image below).

No of course I don't think that, but when trying to follow a tutorial exercise word for word so less likely to go wrong, it is very confusing and discouraging when you can't make things work or your results don't match as it leads you to expect.

However, I was struck by your video apparently by-passing some of what the exercise test tells you, so I tried copying it and to my surprise I managed to assemble the clamp on the pole.

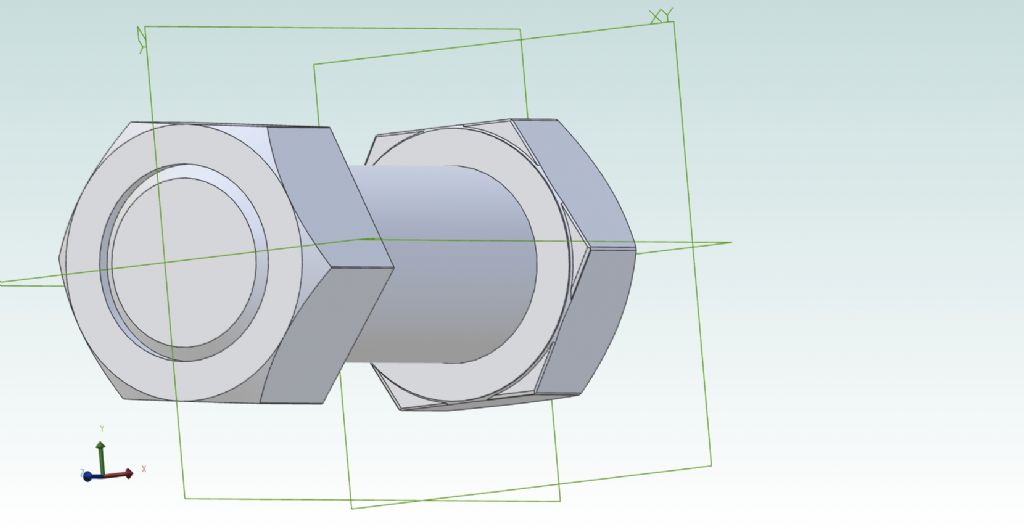

So I tried putting the rest together. That was one monumental battle, at one point welding the thumb-wheel inside the clamp. I had to close and re-open the file to sort that out, and eventually succeeded, leaving a trail of at least 20 constraints and any number of "Undos" just in the second attempt at what an expert would doubtless knock off in ten minutes with no mistakes.

.

I noticed this though. The instructions, if I had read them right, say you put the parts on the screen, then select:

Constraints > Enter the mating surfaces or edges > Constraint type (seems semi-automatic) > Apply > Close,

and watch it slide with eerie grace into place; solid steel through solid steel like a ghost through a wall.

Only, most of the time nothing happened, or it just aligned them in fresh air.. Finally, in desperation I grabbed the part to be added, and slid it by brute force and ignorance into place. It seemed to work, as if the Closed Constraints menu was still active out of sight.

Whether the assembly is accurate is another matter. Aligning the collar and pin-holes was very difficult, as much by eye as by constraints that did not seem to do anything. I suspect if you could view it transparently you'd see the scriber has made the hole in the pin oval.

As for what plane it's on…. More planet than plane. The two vertical planes are XY and YZ, the floor is XZ, and the little trident symbol was pointing anywhere but the normal, positive-going (x, y, z) directions. No idea why. I imagine you've no hope of depicting more complicated assemblies like engines or workshop machines, perhaps from sub-assemblies as well as individual parts, if you've no idea how to align the planes and orientations properly and coherently across all the drawings.

'

Oh, and I reverted to using the previous pointer despite it having no scroll-wheel, and this time everything seemed to respond as it should when selected.

'

Learning 3D CAD to use to design engineering things to make? I'll be past making porridge by the time I manage to reach that level with CAD, if I ever do.

PS: I don't sharpen my real scribers to such a long point! This one is a Chamfer set by guesswork after failing to make the Revolve Cut tool work.

Edited By Nigel Graham 2 on 03/05/2023 16:48:22

Edited By Nigel Graham 2 on 03/05/2023 16:51:30

lee webster.