How on Earth did the designers of those fine old vehicles manage with loose Tee-Squares, 2H pencils and a book of log. tables?

Light-bulb? I'm afraid the bulb's blown…..

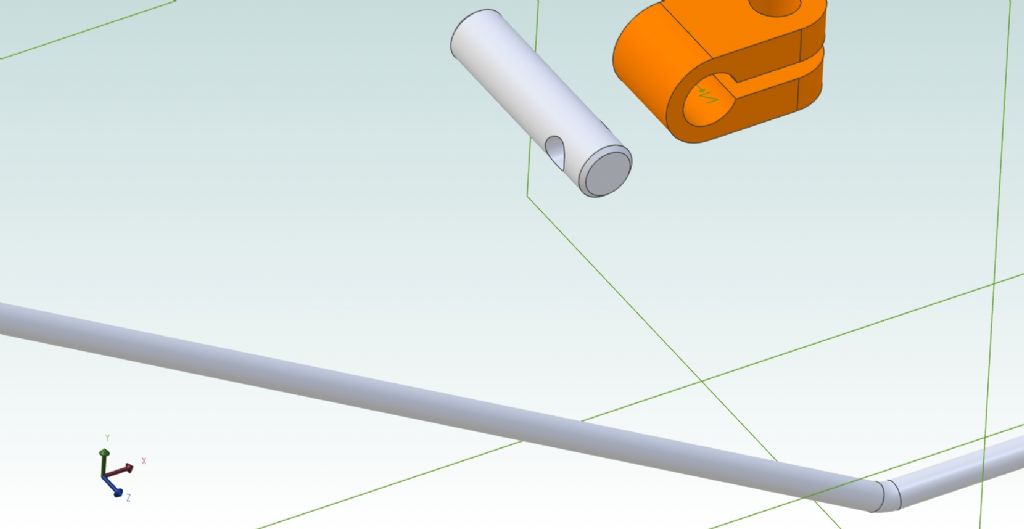

I have just spent some two hours going back over that scribing-block exercise to work out why and where the Clamp ends up on its side, making the Assembly process even harder. So I set out to re-draw that one part from new. It's the orange block in this picture, with the hole and keyhole-shaped slot; and is on its side there: the column goes through the keyhole.

I followed the words very carefully but it all went to pot, even worse than first time.

I had enormous problems with various tools' selections taking many clicks to respond. The Escape key often took several presses to clear, and the Undo arrow suggested big stacks of hidden moves by taking many presses to turn to grey.

.

To cut the slot you extrude a sketched rectangle through it. That bit was easy but the Rectangle tool just would not respond at all. I had to construct it by separate lines away off the block itself then struggle to chivvy it into the right place without knowing how to move sketch objects properly.

Eventually I managed it, though somehow missed radiusing the outer ends. The photo is of my first attempt, not this second one.

'

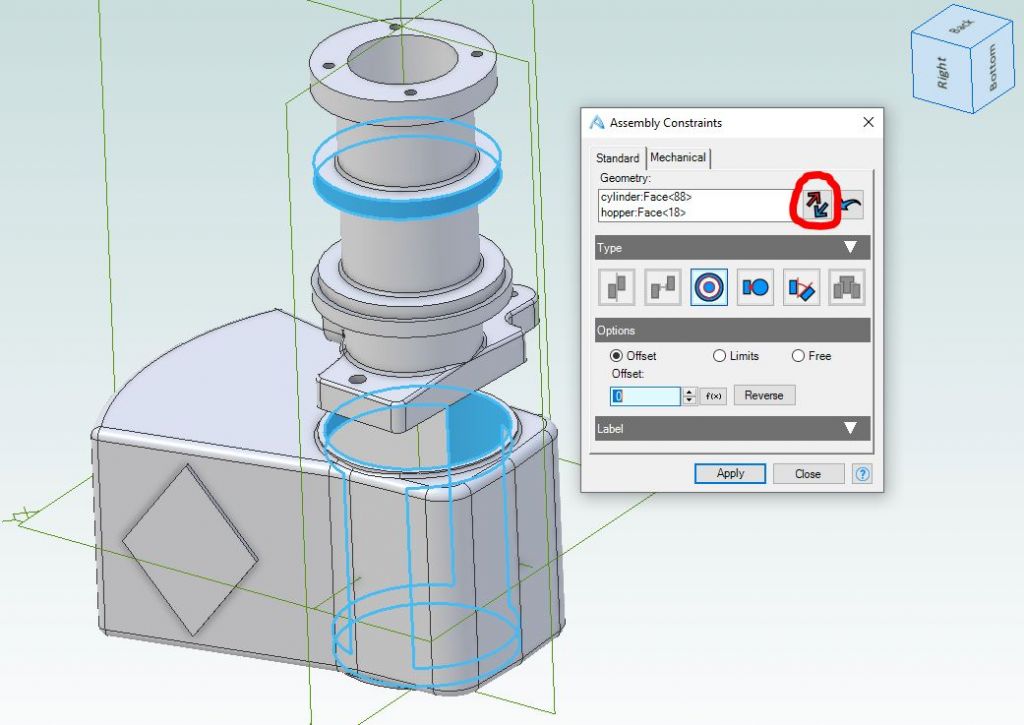

Then tried to Assemble it as the exercise text tells you. It just went haywire.

.

Could the mouse I've just bought be faulty? I don't think it is. A dodgy switch might account for tools not responding to being clicked on, but other mouse moves work. Nor would it account for the Escape key not always responding immediately. I could test this by reverting to the previous device, though it has no proper scroll facility.

'

Progress? Interesting? One way to describe it….

Aye – Alibre is easier than other CAD makes I've tried, and I was making "progress" at first; 2 steps forwards, 1 back.

It's now 2 forwards, 3 back.

Any complicated software is a long uphill struggle for me; but I expected the footpath to reach the summit eventually, not fade away in the foot of the scree-slope.

lee webster.

may well point to exactly what went wrong. Much more instructive to talk through a file that exhibits some issue, and look at what may have happened / how to fix it. You'll learn more than from getting it right at a first attempt.

may well point to exactly what went wrong. Much more instructive to talk through a file that exhibits some issue, and look at what may have happened / how to fix it. You'll learn more than from getting it right at a first attempt.