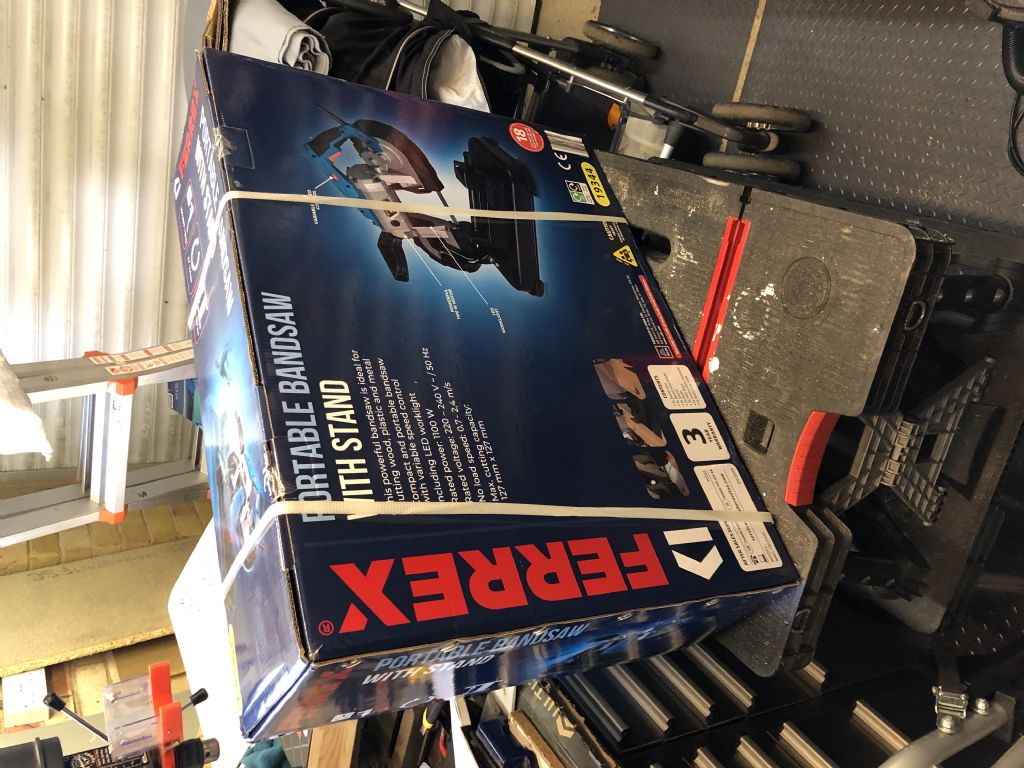

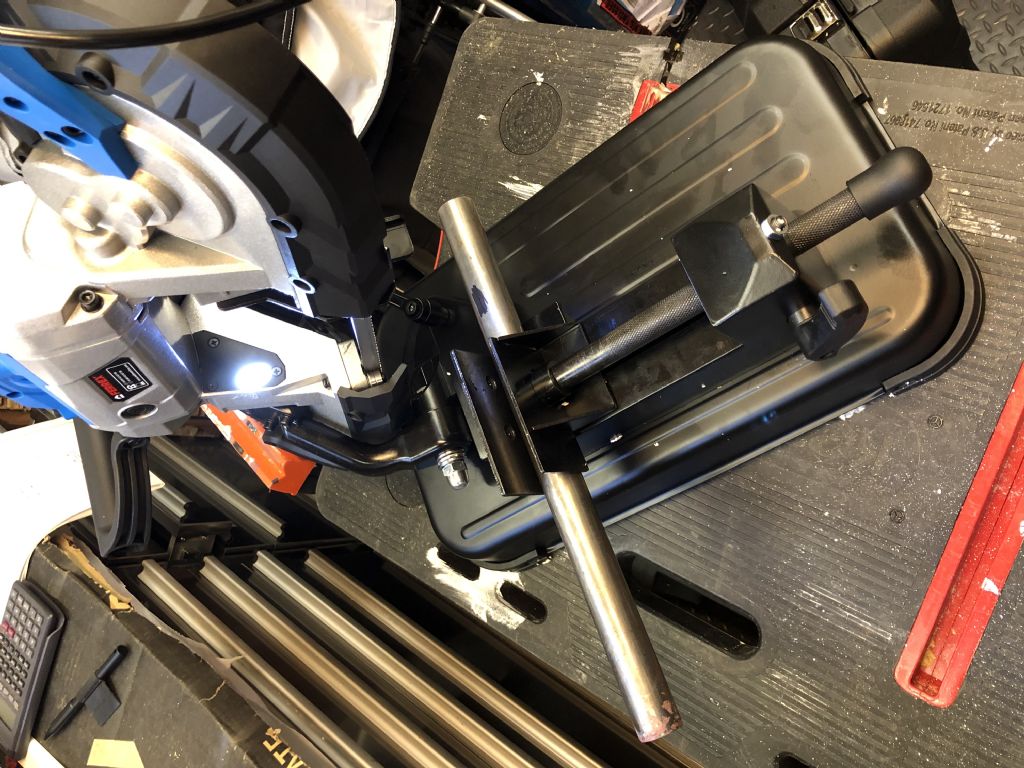

This thread started when the aldi offering was a small vertical bandsaw suitable for wood. It has included replies about disc blade metal cutters (rage type) scroll saws, their cheaper vertical metal bandsaw and now the typical hobby metal worker horizontal band saw (which can be used in three modes – horizontal, vertical with an added table or freehand)

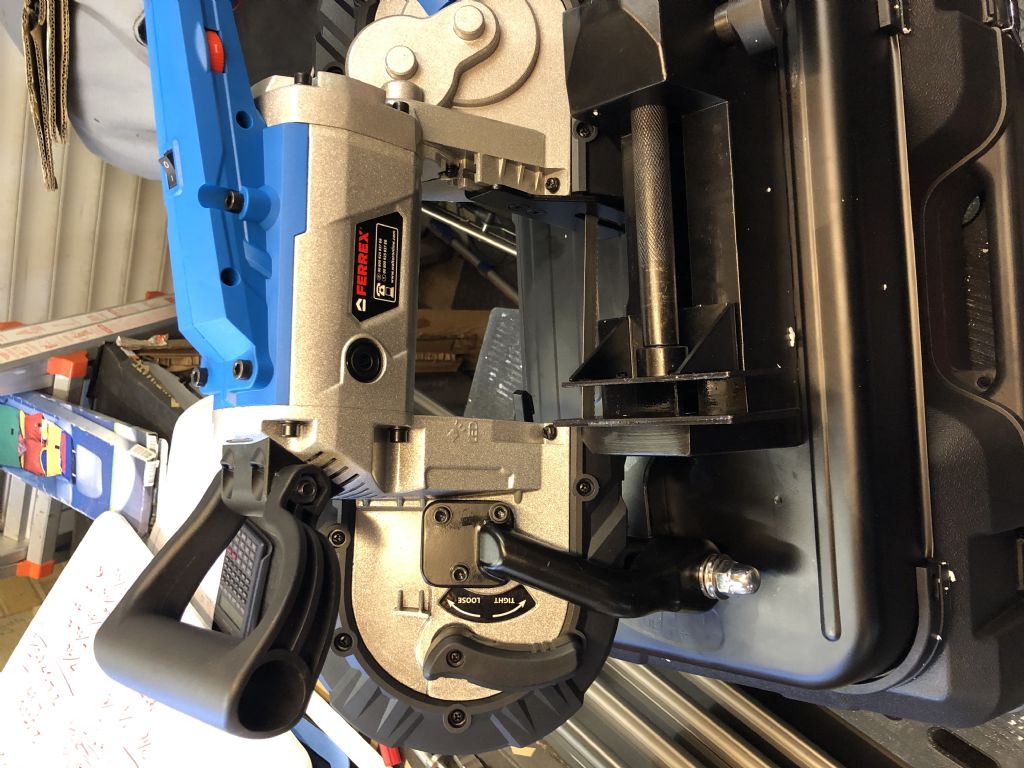

This latest offering appears to be good value for money if it does the job – what with a three year warranty – if a straight cut is all you will ever need. I somehow doubt the saw delivers the power stated – more like power input – so the run-cycle might just need watching.

Just be aware that wearing it out in 3 years will not be what it is warranted for. Doubtless just manufacturing defects if most of these warranties are to be read carefully.

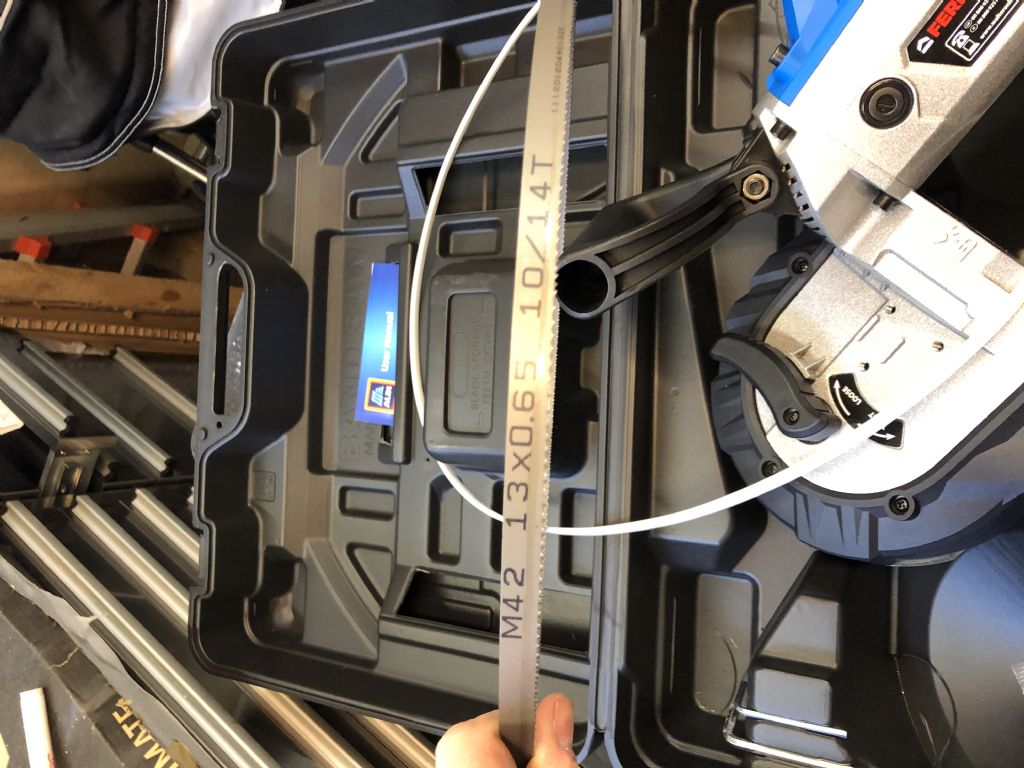

Personally, I preferred a slightly(?) more robust machine with swivel head (worth an extra fifty quid at least, I reckon). Likely a better blade (is the aldi blade just a carbon steel offering, which may mean further outlay fairly soon?). I’m not sure if mine can be easily converted to vertical operation and I have no wish to use it free-hand.

So, as a cheap option, the aldi looks quite good value – if it suits your needs, suits your pocket and doesn’t wear out too quickly. Most certainly better than no saw at all if, like me, manual hacksawing hacks me off these days!

Edited to add that the more expensive ones likely have a ‘no volts’ starter fitted as standard, an auto stop when the cut is completed and will operate without the switch being held in the on position by the operator (or rigged with some form of trigger-holding device – which may cause motor overheat if used continuously?).

Edited By not done it yet on 08/12/2019 08:18:26

Henry Brown.